POWER NEED

With roots that date back to 1907, Saint Peter’s University Hospital is one of the few remaining Catholic hospitals in New Jersey. Based in New Brunswick, NJ, the non-profit acute care hospital provides a full scope of adult medical and surgical services.

The Children’s Hospital at Saint Peter’s University Hospital offers a full range of specialized pediatric healthcare services for newborns and children. Known as a regional leader in maternal health, it operates one of the largest maternity services in the country with over 5,000 deliveries per year. Its neonatal intensive care unit is nationally recognized by U.S. News & World Report as one of the top 50 in the United States.

Saint Peter’s is designated by the state of New Jersey as a Specialty Acute Care Children’s Hospital, Regional Perinatal Center, and Stroke Center and sponsors accredited residency programs in Internal Medicine, Obstetrics and Gynecology and Pediatrics. The teaching hospital is a clinical affiliate of Rutgers University’s academic health center, Rutgers Biomedical and Health Sciences, providing full-time training to as many as 50 students in their third or fourth years of medical school. It also has a clinical affiliation with The Children’s Hospital of Philadelphia.

In 2011, Saint Peter’s embarked on an energy-savings initiative that included a comprehensive upgrade of electrical systems and installation of LED lighting throughout the hospital campus. In 2012, more than 10,000 solar panels were installed in four locations that provide about 20 percent (2.1 MW) of the campus’ energy demand. The combined solar system is expected to save Saint Peter’s approximately $10 million in electricity costs over the next 25 years.

SOLUTION

Three years ago, the hospital doubled down on its commitment to energy efficiency when it began the installation of a 2 MW combined heat and power (CHP) plant, powered by a Cat® G3516H generator set fueled by natural gas.

“The cogeneration plant was part of a natural evolution over a period of years,” says Leslie D. Hirsch, FACHE, president and CEO of Saint Peter’s Healthcare System. “We’ve invested about $10 million upgrading our entire electrical system, and we’ve had a wonderful relationship with PSE&G as well as the state of New Jersey Economic Development Authority and have benefited from grants and low interest loans. We were one of the first hospitals in the state to really focus on resilient energy.”

The $9.2 million CHP project was made possible by a $6.5 million grant from the U.S. Department of Housing and Urban Development for climate mitigation and disaster resilience, as well as a 10-year $1 million interest-free loan from PSE&G, which enabled the project to be launched sooner, as it covered portions of the project not covered by the grant or a low-interest loan, according to Garrick Stoldt, CFO of Saint Peter’s Healthcare System.

“Now that we have CHP, we’re fully operational 24/7 anywhere in the organization in the event of a loss of utility power covered by a storm or other outside event,” Stoldt says. “That is especially significant for emergency medicine. We’ve become a refuge for our community in times of emergency.”

When Superstorm Sandy lashed the region in October 2012, knocking out grid power, many people came to Saint Peter’s seeking shelter and treatment. But with emergency generators providing backup to just the critical areas of the hospital, Saint Peter’s lacked additional power to provide more than just emergency and inpatient care.

With the startup of the CHP plant in late 2018, Saint Peter’s has the ability to operate in island mode in the event of a utility outage. It provides more power beyond the capacity of the four Cat diesel backup generators.

“The Caterpillar cogeneration plant is absolutely a game changer for us in terms of responding to natural disasters,” Hirsch says. “I’ve had some personal experience with Hurricane Katrina, Hurricane Irene and Superstorm Sandy before I joined Saint Peter’s, and in each of those disasters, one of the common elements was limited power.”

“During a natural disaster, when you lose the electric utility and go on backup generator power, much of your operating function in the hospital is limited,” Hirsch continues. “Some areas have full power and some areas don’t. Your clinical functions are limited. The fact that Saint Peter’s now has this cogen plant really makes us an island unto ourselves. It gives us the ability to function under normal and adverse circumstances with full power.”

“Most hospitals do not have 24/7 full-power mechanisms when the utility grid goes down due to a disaster. We, on the other hand, have that power 24/7—and that makes us unique in the state.”

In the aftermath of Superstorm Sandy, many communities were without power for an extended period, and diesel fuel required to run backup generators was in short supply.

“The CHP system has given Saint Peter’s an extra level of resiliency because it burns natural gas,” observes Doug Boyler, chief engineer at Saint Peter’s. “Diesel fuel was hard to get during Sandy, so this really strengthens us during a situation like a bad hurricane where we can run in island mode—it’s a security blanket.”

RESULTS

With the addition of solar energy and cogeneration, Saint Peter’s has extremely low utility energy usage compared to other hospitals in the state of New Jersey, averaging about 1 to 1-1/2 kilowatt hours per square foot (kWh/ft2). The average New Jersey hospital can operate at about 3-1/2 to 4 kWh/ft2.

By running its CHP plant continuously, Saint Peter’s avoids the peak utility demand charge, saving $200,000 to $300,000 per year in energy costs.

Another benefit of the CHP system is that it provides coverage for future expansion of the hospital. A dilemma many hospitals face is that when they contemplate new building additions, the capacity of emergency diesel backup power becomes stretched. Cogeneration makes the most sense, particularly given that hospitals tend to operate on thin margins.

“We’ve actually future-proofed our hospital because most hospitals are at the very end of their load capabilities,” says Andrew Schober, director of Engineering and Project Management at Saint Peter’s. “They’re teetering on needing to add more infrastructure, but prior to doing anything else, they need to add standby or prime power to back up the additional load.

“If we added another 500 kW or even 1000 kW in supported infrastructure, we would still be in almost that same footprint of energy usage with our CHP plant,” Schober says. “It’s actually to the point where I’m not looking at energy efficiency projects as my number one priority until I build more buildings. I don’t think there’s another hospital in the country that can say that.”

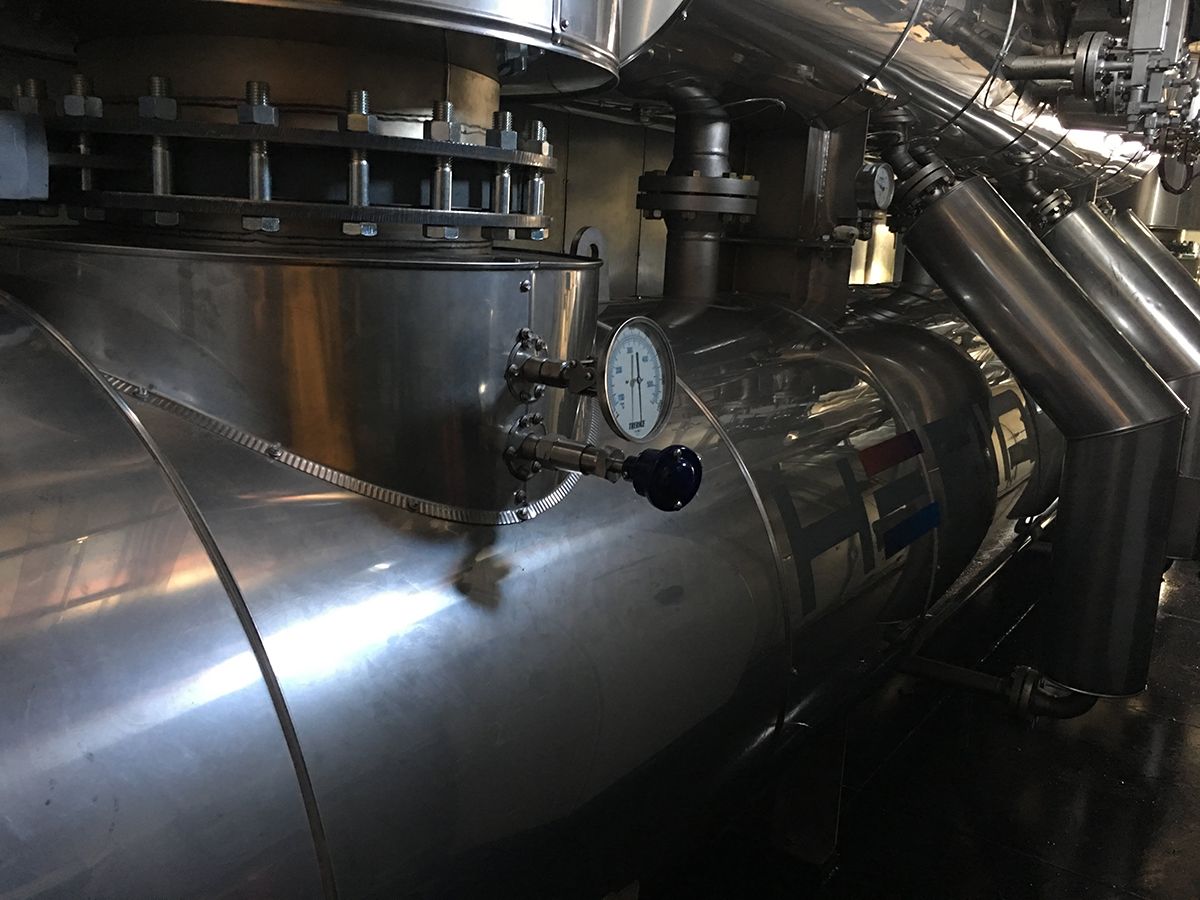

Energy efficiency is another signature piece of the cogeneration plant. The Cat G3516H was engineered to deliver best-in-class electrical efficiency and run for extended periods between maintenance intervals, which increases uptime and reduces owning and operating costs.

Additionally, the G3516H has the highest power density, highest recoverable jacket water temperature, and lowest natural gas fuel pressure. These features helped the hospital install the equipment in a tight space, use the recovered hot water heat efficiently throughout the year, and fuel the generator without concern given the local gas utility’s system pressure limitations.

Waste heat from the Cat generator set is recovered, resulting in Saint Peter’s cogeneration plant operating at 75 percent or greater combined efficiency. Jacket water and exhaust heat from the generator are transformed via heat exchangers to produce hot water and steam that is used throughout the hospital. This “free” heat reduces the hospital’s need to produce heat by 20 to 25 percent.

“We’re not fully running the boilers at 100 percent, which gives us a lot more capacity if we were to need it,” Schober says. “This has been a major windfall for the hospital.”

Based on energy savings, the estimated payback for the CHP plant is three years, Stoldt says.

As of the first week of November, the Cat genset had operated for just over 15,000 hours with minimal downtime.

“It’s been running all through the summer and beyond without any downtime at all,” Boyler says. “Our Cat dealer (Foley Power Systems) has been really good, and if we have a problem, they dispatch service personnel that day to get us back up and running.”

Foley Power Systems has an ongoing partnership with the hospital and plays a key role in helping Saint Peter’s achieve its energy efficiency and resiliency goals. The Cat dealer’s Product Support and Service team administers a Long-Term Service Agreement (LTSA) to provide maintenance for the generator and other equipment.

“We take care of scheduled service tasks, and dispatch personnel whenever needed with parts and consumables that are usually in stock at Foley or can be shipped the same day,” says Scott Yappen, director of Business Development for Foley Power Systems. “The net result is that Saint Peter’s enjoys maximum annual uptime and energy production from its equipment.”

Saint Peter’s University Hospital has a long history with Foley dating back to 1988 when the Cat dealer installed the first emergency diesel generator.

“They have installed and maintained our generators,” Schober says. “They provide rental equipment if we need a temporary backup generator, or even a backhoe or a front-end loader for snow removal. They demonstrated that they could provide the best equipment and service for this application. Also, we wanted to go with someone we trust and have a long history, and that was why we chose Foley for this project.

“Over the last two years, we haven’t had a day where there was a critical need that they didn’t help us meet,” Schober adds. “We make a phone call saying we need help, and they understand how critical it is for patient care, and knowing that, people are not going to be in the dark at Saint Peter’s University Hospital.”

Download the Power Profile