DISTRIBUTED GENERATION

Distributed generation can appeal to end users as well, especially where time-of-use or real-time pricing apply. In such cases, the ability to host a distributed resource can give a business a valuable hedge against market price volatility, or enable the profitable sale of energy to the grid. Applications can include:

- �Prime power systems for complete control over reliability and power quality.

Standby power sized to sustain critical production loads (not just bare-minimum emergency needs).

- �Peak shaving systems to minimize demand charges or spikes in costly on-peak utility power usage.

- �Demand response installations, in which the utility dispatches the equipment during times of peak demand on the grid and rewards the host with rate incentives.

Gas engine-generator sets are proven in distributed power applications. Today’s advanced gas engines operate with uptime often approaching 98 percent and with electrical efficiency as high as 45 percent. The latest configurations develop high power output in footprints up to 50 percent smaller than traditional units, providing an excellent fit on space-constrained sites or in small existing engine rooms.

Installation is fast and simple: units can be online and producing power within a few months from the date ordered, at attractive installed system costs from $450 to $600 per kW. Multiple units can readily meet power requirements up to 50 MW; capacity can be added in increments to accommodate planned growth. Gas engines are relatively straightforward to site and permit; emissions can meet the world’s toughest air-quality regulations.

The units perform well in intermittent service, operate efficiently with variable, cyclic loads and readily tolerate high altitude and high ambient temperatures. They are built for flexibility to operate on gases of varying quality, including natural gas, landfill gas and wastewater treatment digester methane. The gas engine technology is simple and well understood; qualified service technicians and replacement parts are readily available worldwide.

CHP does not fit every distributed generation site: Some heat loads are too small to justify a heat-recovery investment. That aside, CHP is generally most feasible where:

- Host facility heat and electric loads coincide.

- Utility electricity prices are relatively high.

- Generator fuel price is relatively low.

- The local utility or government entities offer efficiency incentives.

- Sustainability, energy efficiency, or greenhouse gas reduction goals need to be met.

Sites with high potential for distributed generation with CHP include wastewater treatment plants, hospitals, universities, district energy systems, and process industries such as food, chemicals, petroleum refining and paper.

THE CHP BONUS

CHP enhances the inherent fuel economy of gas engines – overall efficiency of 75 to 80 percent is routine, and efficiencies up to 90 percent are achievable. Figure 2 shows a comparison of total resource efficiency between a power plant and boiler vs. a gas generator set cogeneration system. In general, the potential for greater CHP profitability grows as annual operating hours increase.

Historically, diesel-fueled generators were used for distributed power, operating for as few as 100 to 500 hours per year to help carry the highest daily and seasonal peaks. More recently, as air-quality regulations have grown stricter and diesel fuel prices have risen, gas units have become a preferred generating source. Their lower operating costs can allow them to run economically for only a few hundred hours per year as continuous base-load units, or anywhere in between as electric power market conditions dictate.

For units hosted on customer sites, these extended hours help justify investment in heat-capture equipment. In turn, heat recovery improves economics so that it becomes cost-effective to operate the systems for up to 4,000 annual hours – essentially half the year – or even more. Economically viable CHP configurations can range from complete heat recovery systems optimized for large, continuous process heating demands, to systems with low-cost coolant circuit heat exchangers for limited domestic water or space heating.

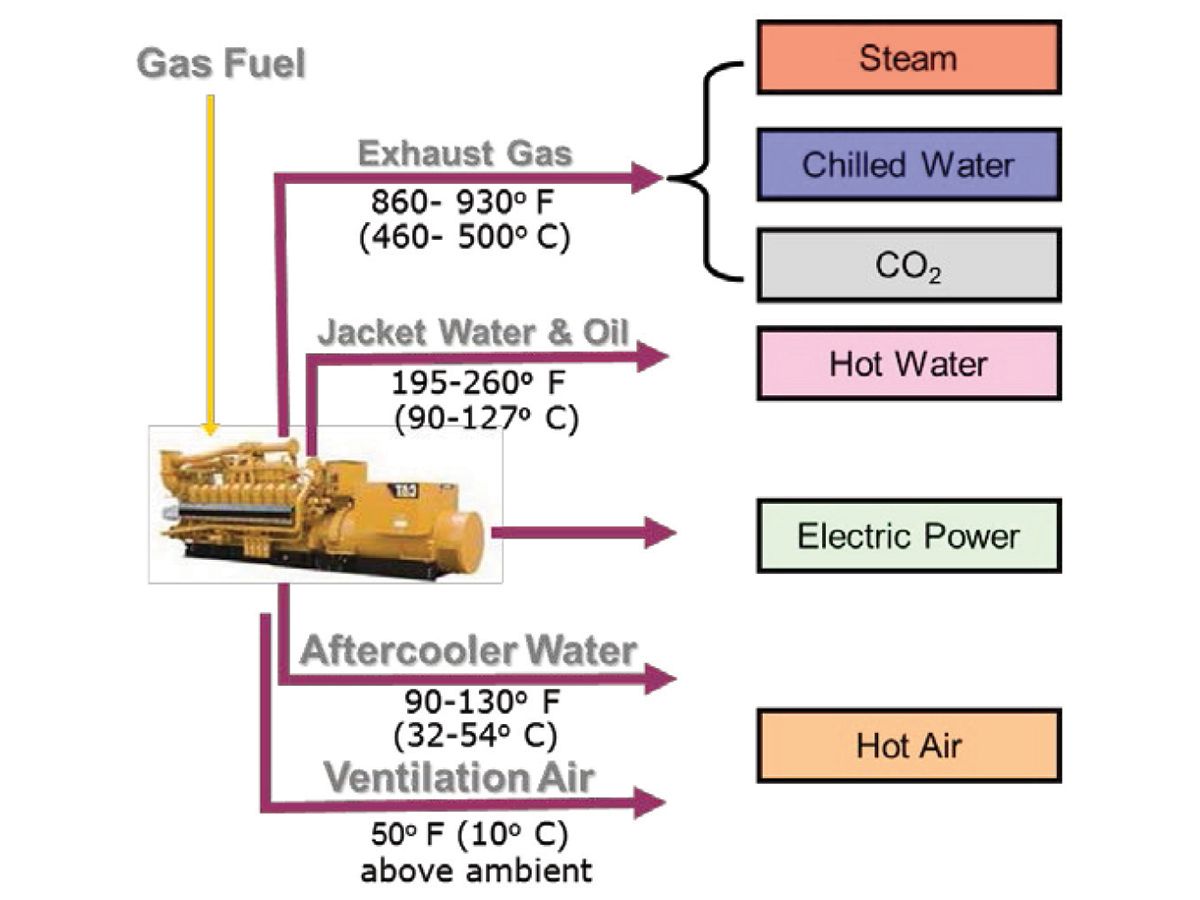

By far, engine exhaust provides the highest temperatures and the greatest heat output. Exhaust heat can generate intermediate pressure steam for purposes like boiler feedwater heating, and low-pressure steam for processes like sterilization, pasteurization, space heating, tank heating, humidification and others. Heat can also be extracted from the engine jacket water, oil cooler and aftercooler to produce warm or hot water for space heating and various industrial processes (See Figure 3).

The essential question is always whether the economic gain from heat recovery offsets the incremental cost of the equipment. Fortunately, CHP is not limited to highly engineered systems. Simple and well-conceived heat recovery can improve the economics of many distributed generation projects with only a modest additional investment.

Economical heat recovery from the engine cooling circuit can be achieved with almost any application that entails roughly 1,000 or more annual operating hours. A simple shell-and-tube or plate-and-frame heat exchanger can produce water at 180 to 210F (82 to 99C), depending on the jacket water temperature.

The captured heat displaces some costs for fuel or utility electricity. To the extent that this heat supports energy needs during times of peak electric load, total electric demand and thus demand charges may also be reduced. If heat recovery from a jacket-water heat exchanger can then partially offset the cost of fuel for space heating, water heating or dehumidification, return on investment improves. Examples of cogeneration include:

- �Commercial real estate. Office buildings can cost-effectively operate generator sets during business hours, avoiding utilities’ highest time-of-use rates.

- �Light industry. A small or mid-sized manufacturer with an onsite generator set could install a heat exchanger in the engine cooling system loop, with a thermostatically controlled diverter valve to regulate the flow to the in-plant load, thus cost-effectively satisfying a variable hot water requirement.

- Hospitality. Hotels can readily use heat recovery for domestic hot water, laundry facilities, kitchens or swimming pool heaters. In summer, the recovered heat can power absorption chillers or desiccant dehumidifiers.

- �Food processing. Food producers can recover jacket water heat for light process loads such as raising dough, or to produce hot water for cleaning and sanitizing. Depending on the size and character of the heat load, such systems can be cost-effective in single- or multiple-shift service, even if heat demand is cyclical or seasonal.

IS IT FEASIBLE?

A first step in exploring a distributed energy/CHP project is to determine whether it meets a standard “five finger test” for electrical project development. A project has potential to go forward if it meets all five of these criteria:

- An air quality permit is attainable at reasonable cost.

- A wastewater discharge permit, if needed, is attainable.

- �Land and building space can accommodate the engines and heat recovery equipment.

- �Natural gas service is available without the need for a costly service upgrade.

- �Electrical interconnection is available at reasonable cost.

Assuming that test is met, the decision comes down to economics. If the distributed generation project is feasible in its own right, then CHP can enhance the bottom line, provided the value of the heat recovered (thermal credit) exceeds the incremental costs to install the heat recovery equipment (principal and interest), and to operate and maintain it (staffing, components, consumables, service, repairs).

MOVING FORWARD

CHP offers opportunities to make distributed generation projects even more financially attractive. These are favorable times to explore CHP as a value-added component of projects that help utilities and their large customers operate more reliably, cost effectively, and sustainably.

ABOUT

About The Author

Diane Clifford is a Market Consultant in Caterpillar Energy Solutions located in Lafayette, Indiana.

About Caterpillar

For more than 90 years, Caterpillar Inc. has been making sustainable progress possible and driving positive change on every continent. Customers turn to Caterpillar to help them develop infrastructure, energy and natural resource assets. With 2017 sales and revenues of $45.462 billion, Caterpillar is the world’s leading manufacturer of construction and mining equipment, diesel and natural gas engines, industrial gas turbines and diesel-electric locomotives. The company principally operates through its three primary segments – Construction Industries, Resource Industries and Energy & Transportation – and also provides financing and related services through its Financial Products segment. For more information, visit caterpillar.com. To connect with us on social media, visit caterpillar.com/social-media.