Customer: Polyus

Location: Eruda, Russia

Customer business issue: Operation on crude oil fuel

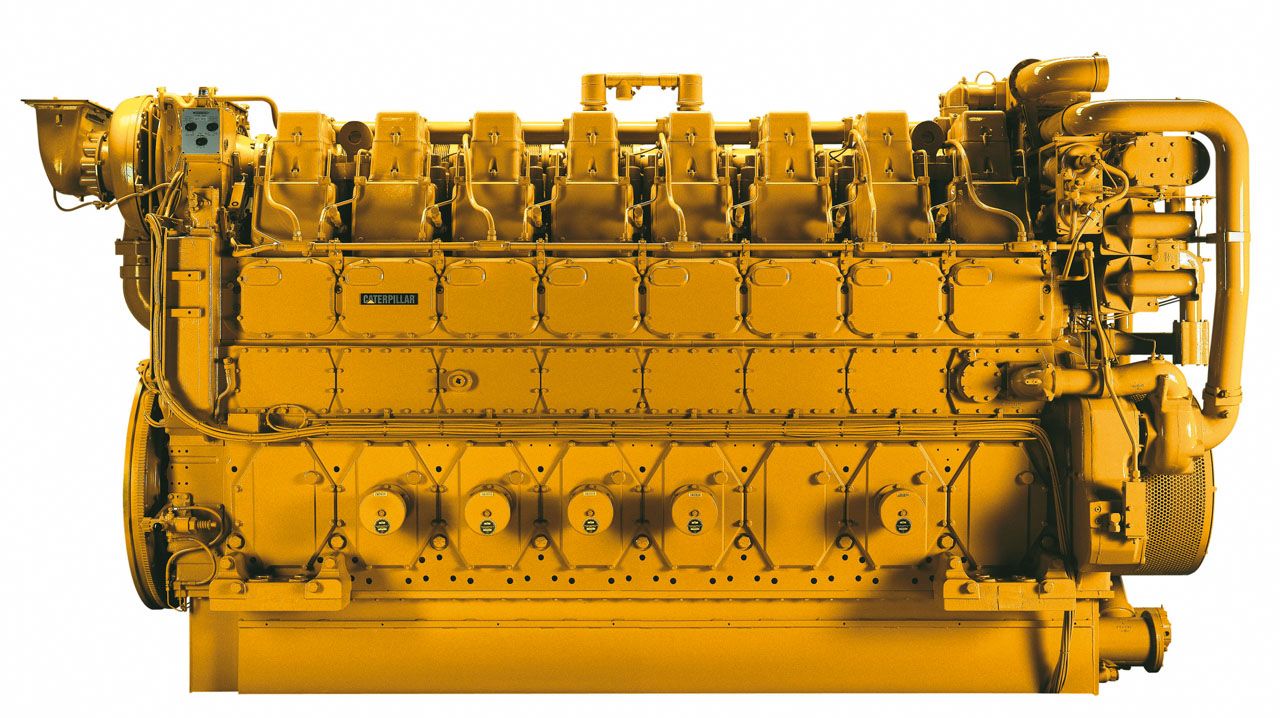

Solution: Four Cat 3616 generator sets

Cat Dealer: Vostochnaya Technica

Headquartered in London, Polyus Gold is one of the world’s largest gold producers. The company operates gold mines in five major regions in Russia – the Krasnoyarsk Territory; the Irkutsk, Magadan and Amur regions; and the Republic of Sakha (Yakutia). Additional mining operations are located in the Republic of Kazakhstan, Romania and Kyrgyzstan.

Because the delivery of diesel fuel to the operations in the northern and western regions of Russia is expensive, Polyus uses crude oil, the local energy resource, in place of diesel fuel to power its operations. Polyus’ power generation needs were twofold: they needed enough power to mine gold, and they needed to provide heat for the surrounding residential settlements and facilities.

At the end of 2008, a crude oil-powered combined heat and power (CHP) plant was commissioned by Polyus in the village of Eruda in the North Yeniseisk region of the Krasnoyarsk Territory. The 17.2 MW CHP plant, run by four Cat® 3616 generator sets rated at 4.3 MW, is the first power plant in Russia to run on crude oil. The Cat generator sets being used there were specifically designed to operate on crude oil, and in turn provide Polyus with high output and reliability at a low operating cost.

The Cat 3616 generator sets were supplied by Vostochnaya Technica LLC (VT), the local Cat Dealer in Siberia, Yakutia and northeast Russia. The CHP plant was designed by ZAO Polyus.

Ella Udodova, the project manager of VT, notes, “In the winter, the temperature in this region reaches as low as -50°C (-58°F) so constructing an oil pipeline is both economically challenging and risky. Delivering oil by truck from the nearby Yurubcheno-Takhomskoye oil field to the village of Eruda is the safest and most economical solution.”

The delivered oil is stored in tanks near the CHP plant. These tanks include 12 outdoor, 3,000-square-meter (32,200-square-foot) tanks; two 25-square-meter (270-squarefoot) daily tanks inside the building; and one 5-square-meter (54-square-foot) tank at the separator. A fuel preparation unit separates the crude oil from water and mechanical impurities, heats it to the preset temperature and maintains fuel pressure. The multi-stage oil fuel filtration provides purity of up to 12 μm.

The Cat 3616 generator sets feature fourcycle, V-type, 16-cylinder engines with direct fuel injection and turbochargers. The fuel system includes a fuel pump, pump-injector units and double fuel filters. The unit has a differentiated cooling system with an expansion tank, which is mandatory for heavy-oil engines. The cooling circuit of the engine’s jacket and the cooling circuits of turbocharged air and oil are separate and maintain temperatures of 90°C (194°F) and 32°C (90°F), respectively. Each generator set is equipped with an exhaust heat recovery system and a module of heat exchangers.

A closed circuit lubrication system is used in the engine. It includes a gear wheel pump driven by the engine, a 1,600-liter (420-gallon) oil pan, an oil-to-water heat exchanger, oil filters, a dip stick and a filler neck. The engine prelubrication system is operated pneumatically.

An air engine start system with electronic control system is used. The digital control system regulates the engine speed and loading of the drive. The actuator is engine mounted and the control unit is placed on the control board. The engine has overheat protection, overspeed protection and low oil pressure protection. The engine and the generator have isolation pads installed between the frame and the concrete foundation. The AC electric generator is a brushless, synchronous generator. The capacity of the generator is 5400 kVA and its output voltage is 6.3 kV.

The generator is designed to carry 110 percent overloading during two hours when operating as a main or permanent power unit, as well as short circuit current exceeding the operating current by 300 percent during 10 seconds.

Because of the geographic location of the CHP plant, the delivery of the 64-ton units was the most difficult task and required some treacherous route negotiation. The situation was further complicated by bad weather conditions in Russia and a hurricane along the transport route in the U.S. In spite of these difficulties, the Cat 3616 generator sets were delivered on time by the VT team.

Power generation for Polyus is now easier and more cost-efficient with Cat engine technology and VT service support. The CHP plant in Eruda significantly reduces the cost of generated power while at the same time improving its quality. All systems are highly automated, which makes it possible to operate the CHP plant with a staff of 30. The CHP plant is supplying reliable electrical and heat power to the mining facilities as well as to the surrounding village.

For your largest power needs in any environment, Cat?� 3616 Industrial Diesel Engines offer the unsurpassed performance and durability your customers need to keep their industrial applications and operations running. They deliver high power output, proven reliability and excellent fuel efficiency. These engines maintain low operating costs to keep your customers profitable for years to come. Industries powered by 3616 engines include Construction, Forestry, General Industrial, Material Handling and Mining. These 3616 engines, with ratings: 4160-4920 bkW (5579-6598 bhp) @ 800-1000 rpm, are non-certified and are available for global non-regulated areas.

Learn More