Customer: Nong Rai Farm

Location: Rayong, Thailand

Scope of engine use: Cat® G3406, G3306

Cat Dealer: Metro Machinery Co., Ltd., Bangkok, Thailand

Nong Rai Farm was seeking a means of tapping its biogas resources to fuel electrical generators for on-site power. The farm partners with the CP Group, one of the largest food suppliers in Thailand, operates a feeder operation for more than 30,000 hogs in Rayong, Thailand. Nong Rai Farm consumes approximately 200 kW of power for blowers, drying systems, and other auxiliary needs associated with its operations. The manure produced by its hogs is piped into a digester pond, where it generates biogas that is used to fuel the generator sets. The generators produce power sufficient for all of Nong Rai Farm's electric power requirements.

Nong Rai Farm selected Caterpillar generator sets because of the anticipated long-term benefits of using their high-quality and reliable generator sets over other, low-cost gas generators, often modified from automotive engines. While Nong Rai Farms recognized that the initial investment in Caterpillar biogas-fueled generator sets would higher, it was confident that the long-range savings associated with a reliable, durable platform would be significant. As the generator sets would be running continuously, it was important to work with a supplier that could provide guidance on engine care and also have parts available in a timely manner when necessary. Caterpillar was chosen because of its reputation for quality power generating equipment and extensive field validation of similar units operating on methane gas. Another consideration was its capability to provide local service and technical support for the installation through its factory-trained design and maintenance personnel at Metro Machinery Co., Ltd, in Bangkok. In addition, the dealership possessed the experience and expertise necessary for both commissioning and maintaining power projects utilizing ag-biogas.

Metro Machinery Co., Ltd., installed two biogas-fueled Caterpillar generator sets at Nong Rai Farm. These gas generator sets are capable of producing a total of nearly 200 kW. In addition, control panels and automatic transfer switches were installed to ensure that the power generated is distributed reliably and efficiently. This project exemplifies sustainable development. It involves the capture of a waste gas, circumventing the harmful effects on the environment associated with methane migration. Furthermore, any energy created by the methane conversion in the generator set offsets the emissions that would be created if power was supplied by a standard coal-fired facility.

Installation of the Caterpillar power system was designed to cut costs for electricity as well as utilize existing on-site biogas resources at Nong Rai Farm; it has met both of these goals. The Nong Rai Farm installation was completed in mid-2005 and has been operating successfully since it came online. Not only is the Nong Rai Farm power plant meeting all of the farm's electric power needs, it is saving the farm approximately 2.8 million baht annually that would have otherwise been spent purchasing electricity from the local power grid.

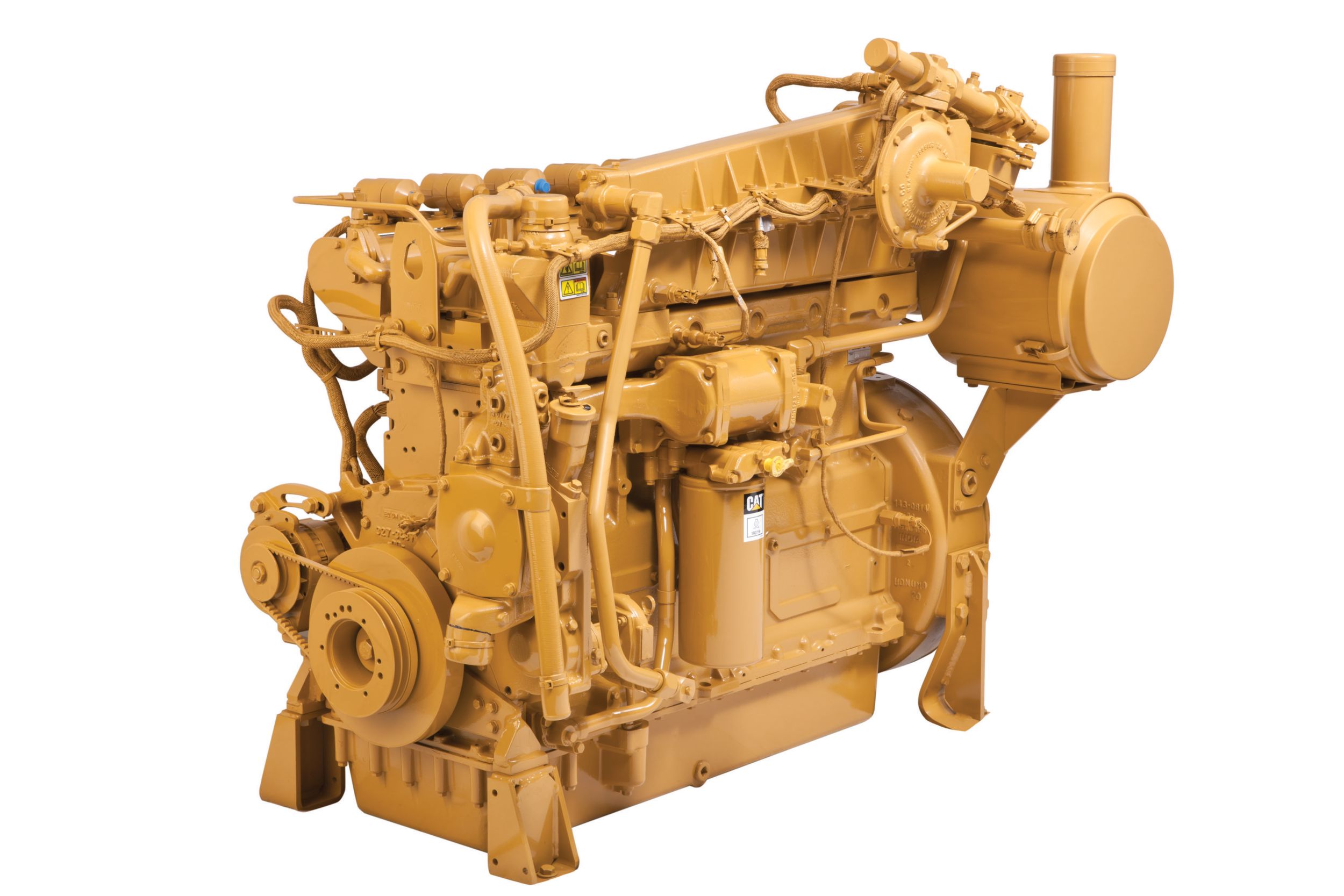

Tough and durable, built on the industry-standard G3300 platform and equipped with technology that brings performance, uptime, and low operating cost to your operation. G3306B engines meet the most demanding continuous duty gas compression applications with virtually no unscheduled downtime. Ideal applications for G3306B engines include gas lift, gas gathering, and wellhead gas compression. Cat G3306B gas engine. Ratings: 108-157 bkW (145-211 bhp) @ 1800 rpm are NSPS site compliant capable with Caterpillar or customer-provided air-fuel ratio control and aftertreatment.

Learn More