Southwestern Energy saves $700,000 in 11 months with Cat® Dynamic Gas Blending™

Customer: Southwestern Energy Company

Location: Fayetteville Shale, Arkansas

Customer Business Issue: Fuel efficiency, emissions

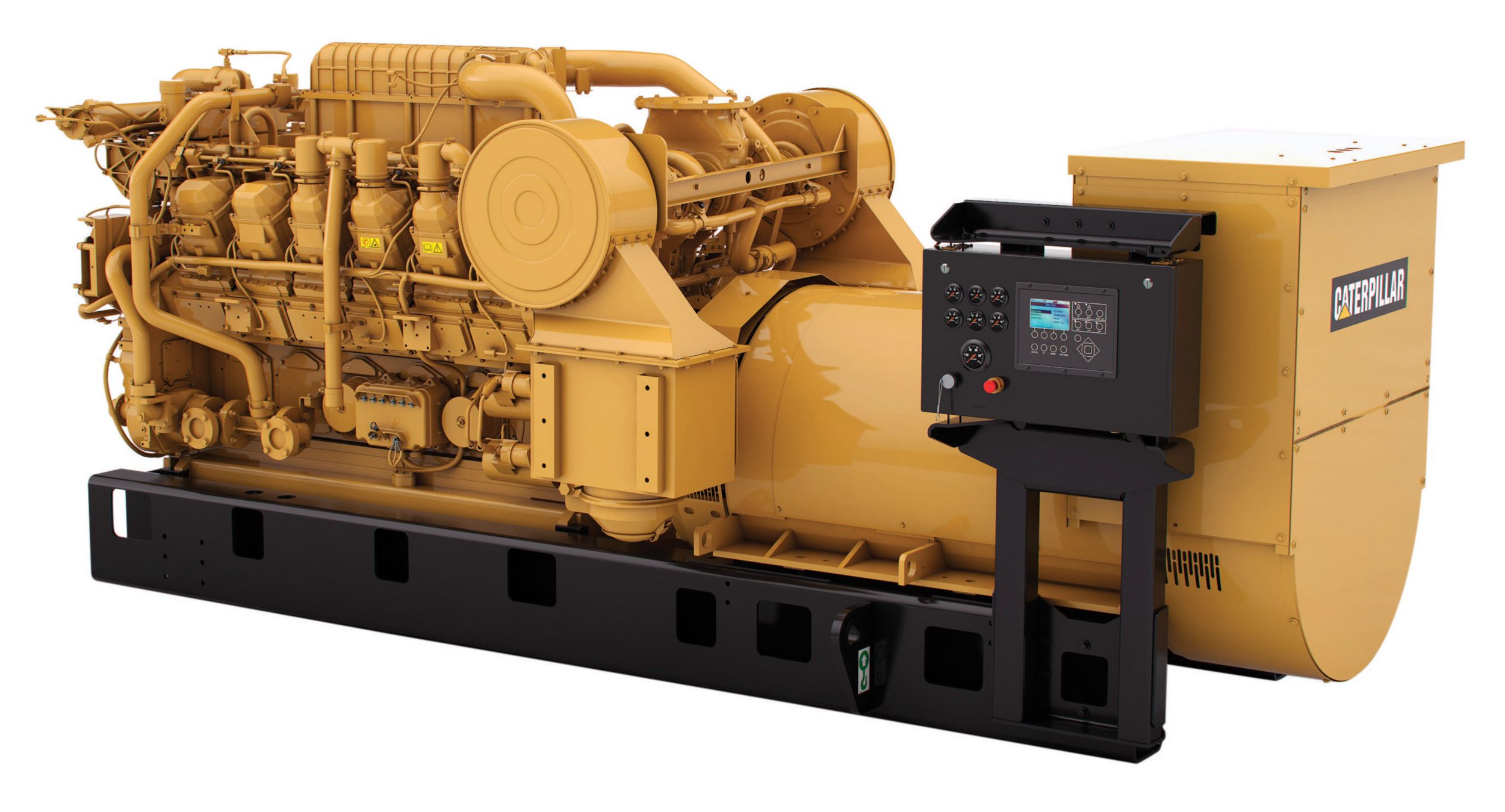

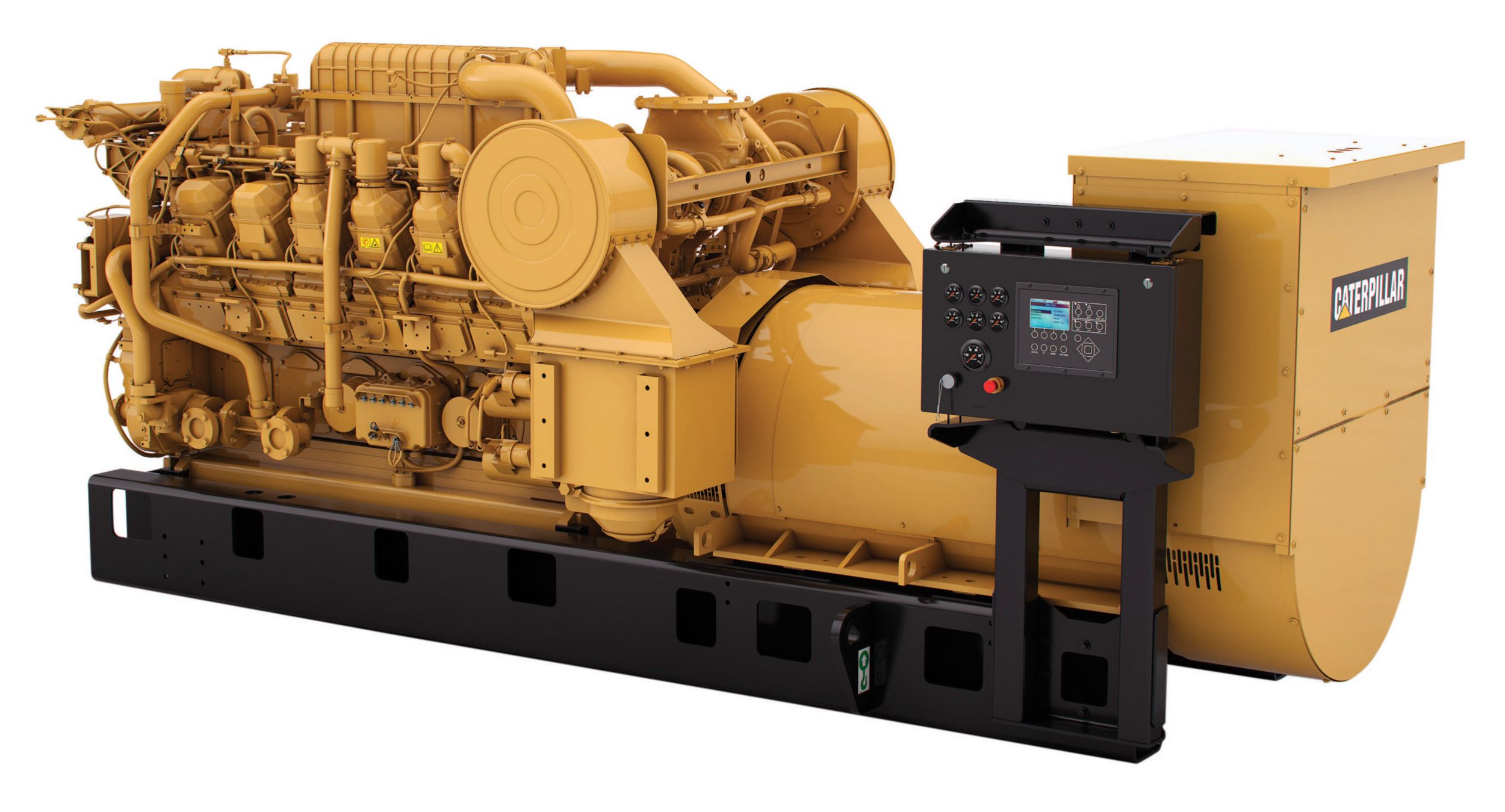

Solution: Two EPA-approved Cat DGB Kits

Two 3512C generator sets

Cat Dealer: Riggs Cat

The Challenge

Emission regulations and fuel costs have created a need for flexible fuel solutions that decrease fuel costs and help meet emission standards.

Southwestern Energy Company (SWN) is an energy and production company headquartered in Houston, Texas. SWN produces from more than 1.5 million acres of land in the Fayetteville and Marcellus Shales.

To minimize high operating costs from diesel fuel, SWN turned to Caterpillar Oil & Gas and Cat dealer Riggs Cat for a dual-fuel solution – Dynamic Gas Blending (DGB™).

The Solution

SWN installed two Cat 3512C land electric-drive drilling modules with EPA-approved DGB kits at a rig site in the Fayetteville Shale. DGB offers fuel savings with up to 70% substitution while maintaining existing service intervals and component life. Cat DGB automatically adjusts to changes in incoming fuel quality, from associated gas to LNG.

“We believe the diversity of this system to run on a blend of natural gas and diesel or on straight diesel is a critical factor in our operation,” said Marty Carley, Vice President, SWN drilling company. “Having the ability to mitigate the downtime created by either natural gas fuel [CNG, LNG, and field gas] availability and/or natural gas fuel quality allows us to maintain the logistic diversity of the rig, if these issues arise.”

“For our team, it was essential we find an OEM capable of not only providing an advanced dual fuel product with full horsepower capabilities; we wanted to partner with a company that could commit to providing around-the-clock support and resources. Caterpillar and Cat dealer Riggs Cat were able to do that for us.”

Marty Carley, Vice President, SWN drilling company

The Results

With DGB installed for 11 months, SWN saved an estimated $700,000 in fuel costs and averaged a 60% substitution rate using gas from a nearby wellhead. In addition, SWN had no increased unexpected downtime.

SWN plans to continue to use Cat DGB kits on their sites to be the market leader in lowest cost per well. SWN is currently building seven new rigs with Cat DGB kits installed.

“The importance of not only continuing to use DGB but growing the use of DGB for our industry should go without question,” said Southwestern Energy Maintenance Manager Mike Gautier. “We are decreasing cost and increasing demand. Anyone who doesn’t understand the importance of that is in the wrong business.”