Showcase Facility

Based in Waltham, Mass., Harvest Power chose to install its third anaerobic digester in Orlando—with Disney as its first and largest supplier of food waste—to showcase the benefits of diverting large-scale food waste and other organic materials away from landfills.

“We really built this plant as a showcase to address some of the waste issues associated with having so many visitors, whether that be hotels or convention centers,” says Jeremy Goodfellow, vice president of energy operations for Harvest Power. “By partnering with local companies who can separate their organic waste, we’re able to process it and bring it to beneficial uses.”

Harvest Power receives payment to accept food waste at its facility located within the Reedy Creek Improvement District just north of Disney attractions.

Organic material comes from theme parks, entertainment areas, resorts, hotels, and convention centers around central Florida. While Disney is its largest supplier, contributing 50 tons per day, other customers include Hilton, Marriott, the Ritz Carlton, Sea World and the Orange County Convention Centers.

That material is blended with fats, oils and grease from restaurant grease traps. The organic waste and grease are mixed together with biosolids from the adjacent Reedy Creek wastewater treatment plant, then pumped into the anaerobic digester tanks.

The biogas that results is about 70 percent methane, which is used to power two Cat G3520C generator sets that create about 3.2 MW of electricity. The digester facility uses about 20 percent of the electricity generated, and sells the rest to the power grid.

After a period of about 30 days, the digested organic material is dewatered, and the solids create a black powdery fertilizer, which is sold to area farmers and nurseries. Heat from the generator exhaust is used to help dry the material.

“The fertilizer is used to grow more food, which comes back to central Florida and is sold in produce markets, grocery stores and restaurants,” says Chris Peters, a regional vice president for Harvest Power. “So it’s a closed loop where the organics that are normally going to landfill and would have been wasted come to us to be used for renewable energy and fertilizer. The nutrients go back into the ground to be reused.”

Orlando and the central Florida region represent a unique community, with approximately 58 million visitors annually. The “Orlando or Landfill?” responsible food recovery campaign challenges businesses and consumers to reduce pressure on landfills and help fuel local renewable energy production. Harvest Power works with a variety of municipalities and private haulers to provide simple solutions for food waste recycling.

“This facility really shows what you can do when you put your mind to creating a sustainable environment,” Peters says of the Central Florida Energy Garden, which was fully commissioned in December 2013. “This facility signals a paradigm shift for the region’s hospitality industry as hotels and restaurants are now able to differentiate themselves to customers through environmentally sound waste recycling practices.”

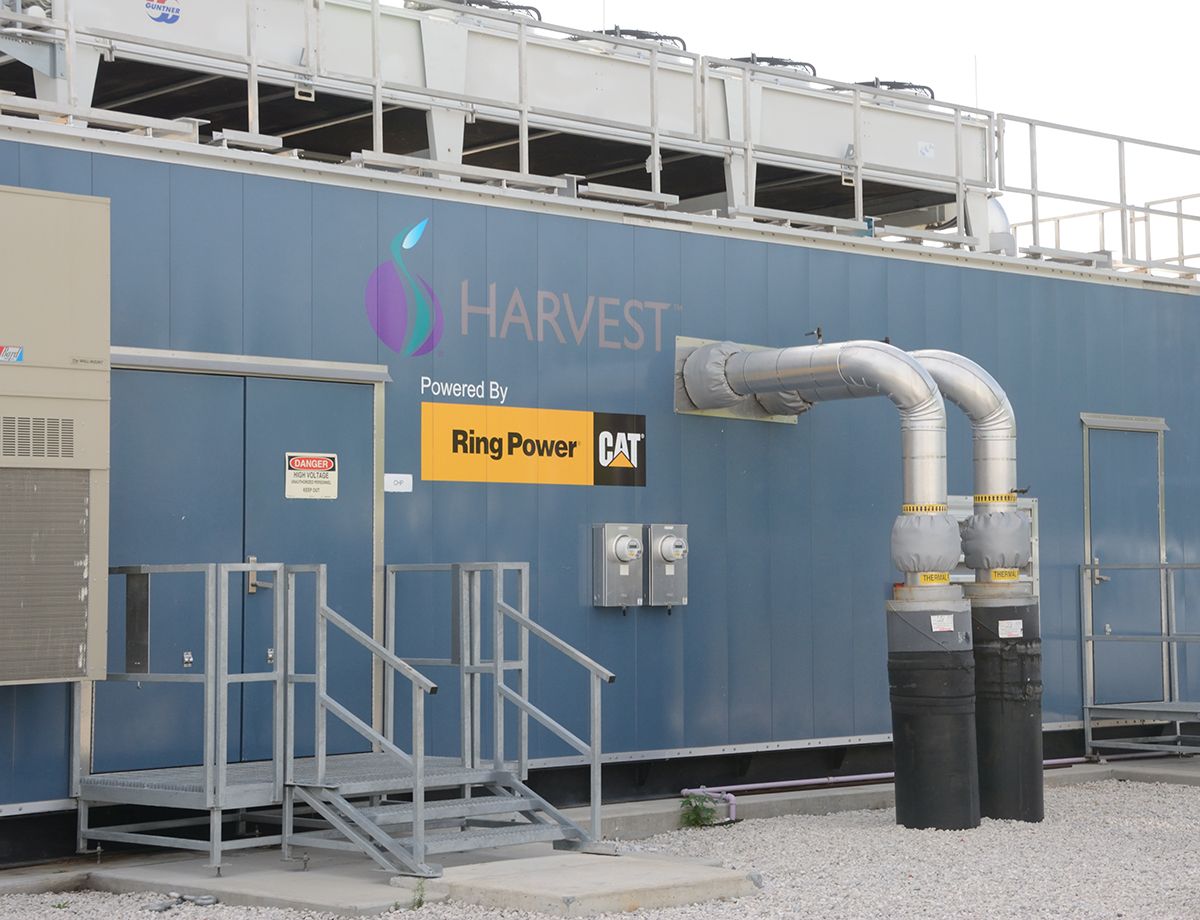

Ring Power a Partner

The Cat generator sets are placed inside a specially designed enclosure by Phoenix Products, a division of Cat dealer Ring Power. Switchgear and customer connection points are located just outside the generator room.

Financing for the generator sets and ancillary connections was provided by Cat Financial.

More than a year after the plant began operations, the G3520C generator sets have proven to be very reliable.

“The Cat engines are very efficient and capable of handling the variations in biogas,” says Kelly Saikkonen, a facility engineer for Harvest Power-Orlando. “Here at our site we have biogas storage—a double membrane system—and the level in that membrane fluctuates based on gas production and gas levels. The software that controls the Cat gensets interfaces with our facility software to increase and decrease the load on the generators based on biogas levels. The system works in auto mode, and it’s very efficient in increasing or decreasing the loads on the gensets based on biogas availability.”

Having grown to more than 450 employees, Harvest Power has taken the next step in organics management, going beyond traditional composting of organic matter to creating electricity and thermal energy from those organic materials. The evolution of composting and what organics management will mean to North America is central to the company’s vision for the future. To realize that vision, it takes partners who share the same values, Peters says.

“Having a showcase facility here in Orlando and having partners like Disney, Reedy Creek, Marriott, the Hilton Group and Waldorf—those are large brands,” Peters says. “They are very concerned about sustainability and the environment. So we wanted partners who also held those same values, and we found that Caterpillar and Ring Power wanted us to succeed.

“So it’s a great relationship to have people on your team who don’t care about themselves, but they care about their customers and put the customers first,” Peters says. “We like that.”

Harvest Power counts on Ring Power to take care of the Cat generator sets to ensure they are operating at peak levels. That frees up Harvest to concentrate on what it does best, which is organics management.

“Ring has been with us step by step, making sure that any issues that we have had with the engines or anything with the heat delivery system are resolved quickly,” says Peters. “They have been there to help us maintain it, educate us, and really help us perform to the level that we need for our customers and make sure that we stay online with producing a reliable source of power back to Reedy Creek.”

Read the in-depth details by downloading the Power Profile.