Metro Machinery Co., Ltd., installed two biogas-fueled Caterpillar generator sets at Nong Rai Farm. These gas generator sets are capable of producing a total of nearly 200 kW. In addition, control panels and automatic transfer switches were installed to ensure that the power generated is distributed reliably and efficiently. This project exemplifies sustainable development.

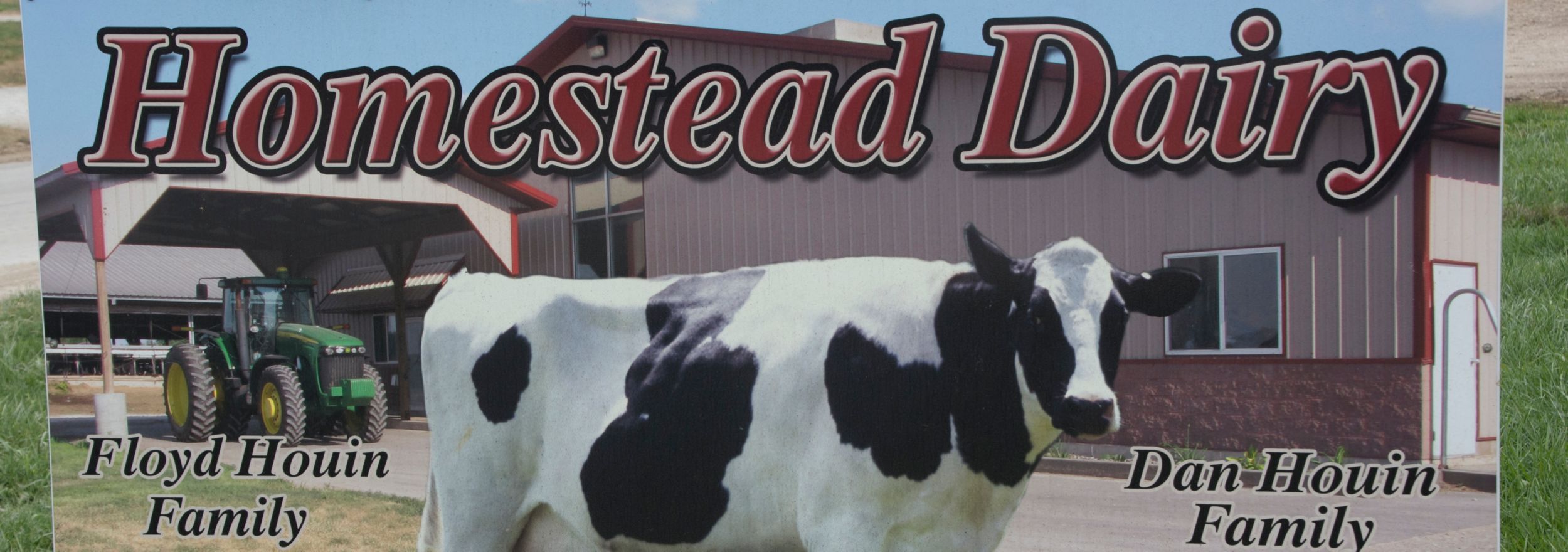

Learn MoreBased in Plymouth, Indiana, Homestead Dairy has 1,800 milking cows and 1,700 cows come in from three nearby facilities for milking. Continued success increased cow manure and the odor was directly impacting the nearby residents. They decided to build a biomass waste-to-energy facility to convert the manure into electric power and Homestead Dairy partnered with local Cat dealer, Michigan Cat, to customize a green energy power generation system.

Learn MoreGranjas RYC is a producer, packager and distributor of meat products. The company produces various cuts of meat, seasoned and marinated meat, lunch meats and sausages. These products are then distributed under different brand names to supermarkets throughout México. The company also operates its own stores in central and southern México. The self-generated electricity powers many facilities on the farm, with most of it consumed by the incandescent heat lamps that keep the piglets warm in the maternity area. The hot water produced from the cogeneration process is used in the farm's locker rooms and swimming pool. By running this generator, the farm realizes a cost savings of approximately $60,000 USD annually.

Learn MoreSeacliff collects vegetable and animal waste from nearby farms and greenhouses, generating enough biogas to fuel a power plant designed and supplied by the local Cat® Dealer, Toromont Cat Power Systems. The facility can currently process up to 40,000 metric tons of organic waste per year, which will increase to 100,000 metric tons once Phase II is complete. At that time, Seacliff will have the largest energy producing anaerobic digester in North America.

Learn MoreBettencourt Dairies discovered a solution that would allow them to resolve the odor and methane issues, while also producing power for the facility and the local grid. Six one-million-gallon anaerobic digesters were installed at Rock Creek Dairy to process manure and mitigate odors. Approximately 200,000 gallons of cow manure are collected daily, pumped through a nearly mile-long pipeline to the digesters and processed into clean compost used for animal bedding. It’s the largest facility of its kind in the country. One of the generators runs continuously while the other unit runs variable hours following biogas production. Both feed power to an electrical transformer located outside the building. Exhaust heat from the engines is used to heat the six digesters.

Learn More