Gert Hoffmeister

Caterpillar® Germany, Nuclear Power Division

ABSTRACT

Nuclear power plants (NPP) need reliable emergency backup power in order to maintain a safe condition after external power failure and to meet related regulations. Comparing two real-life projects upgrades of the emergency backup power infrastructure, it is revealed just how important it is to at early stage possible consider all relevant parameters, including technical requirements, regulatory requirements and site installation conditions. This comparison demonstrates how modular power solutions, like the ones offered by Caterpillar, can shorten project duration, reduce investment cost and project risk.

This paper also introduces to the various levels of emergency power sources at nuclear power plants, their functions, technical requirements and safety classification that can all have an impact on the design and implementation of emergency backup power installations.

INTRODUCTION

Reliable backup power is critical to nuclear power plants. Post Fukushima stress analysis, aging installations and reactor service life extensions pose new challenges to the industry. Many site designs did not foresee the need for additional generator sets, changing requirements or modifications to installations, making it difficult to update outdated facilities and improve reliability of the backup power system.

As outlined in the below case studies, NPPs around the world take different approaches to addressing these problems. And as NPPs continue to age, innovative solutions are needed to keep emergency backup power installations up to code and to provide the highest level of reliability.

Depending on the required safety class as well as Owner and/or Safety Authority regulations, modular systems, built off site, can be very attractive solutions. Caterpillar and Zeppelin CZ developed the first modular backup power installation, overcoming restrictions imposed by the initial plant design and conventional ways of installing backup power sources. This design can bring a new level of flexibility to the industry while fully meeting operators and regulators requirements. Owners and operators receive the highest level of dependability, not only during operation, but during planning and project implementation. By using modular installations, the cost and schedule stay under control throughout the entire project timeline and nuclear power plant service life.

ROLE OF DIESEL GENERATOR SETS IN A NPP

Depending on the reactor type and its level of passive safety systems nuclear power plants rely on backup power immediately or after some time after connection to the main grid is lost and cannot be restored. When the power plant turbine generator fails, the reactor needs to be shut down, steam generation to be reduced as quickly as possible. This typically is achieved by fully inserting all control rods immediately.

After such a reactor trip, residual heat needs to be removed continuously for some days until it is decreased to a low enough level where natural convection is sufficient. Lack of cooling could ultimately result into reactor core damage. Core damage is rated the highest on the accident scale as it destroys the reactor beyond repair and can eventually cause radioactive material to be released into the environment.

Plant auxiliary equipment, like pumps and other electrical drives and lights during normal operation are typically fed from two redundant consumer bus-bar systems using power from the main alternator driven by the steam turbine. In case this main generator set is shut down the operational source of power is lost.

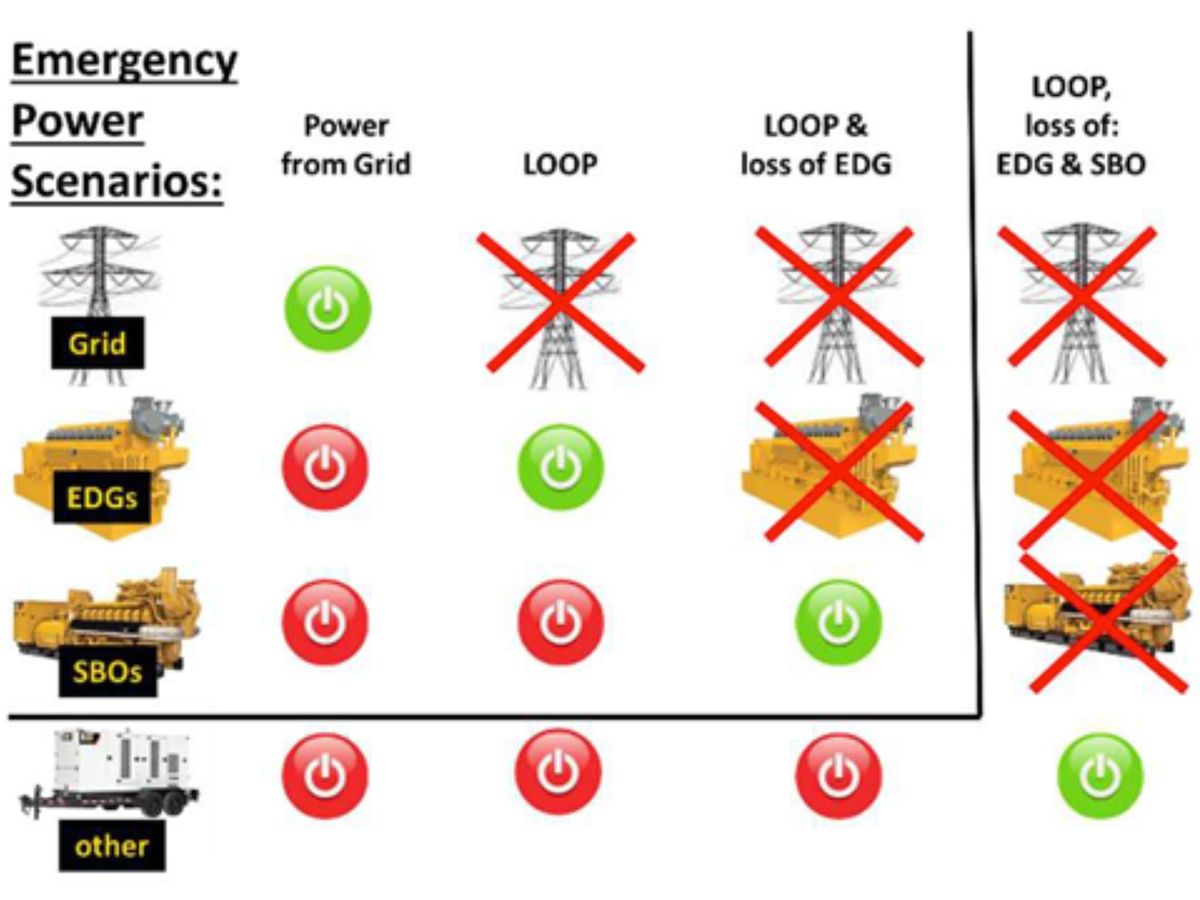

When the external backup power line is no longer available, most nuclear power plants depend on various levels of Diesel engine driven generator sets.

CASE STUDY 1 – SIZEWELL B

At the Sizewell B nuclear power plant in the UK two battery charger generator sets needed to be updated after 30 years. The complete installation was replaced and more stringent requirements for flood protection were imposed on the facility. The new installation had to be installed into the existing building. Customer decided to contract the project to Finning UK using Caterpillar generator sets.

The project was broke down into the following phases: Engineering and planning, civil work on the building to remove the existing generator set, disconnecting the old generator sets from their infrastructure and removing it from site; removing all the related installations, such as piping, cabling, fuel tank, and other small tanks, in order to provide complete clearance and preparation for the new installation; transportation of components and material to the site and into the building; and installation of a new stack, starter batteries, battery chargers, flood protection elevation structure, generator set, fuel tank and interconnecting piping and cabling.

Besides the normal engineering, procurement, logistics, construction and installation services, there were a number of engineering and support challenges that needed to be overcome, including various nuclear and seismic qualifications, extensive testing and documentation.

Each step of the otherwise normal procedure was subject to a multi stage approval process. Especially modifications to the existing structure required special attention and preparation. Any change resulting from conditions discovered during the work needed to go through the approval process again causing extra cost and schedule delay.

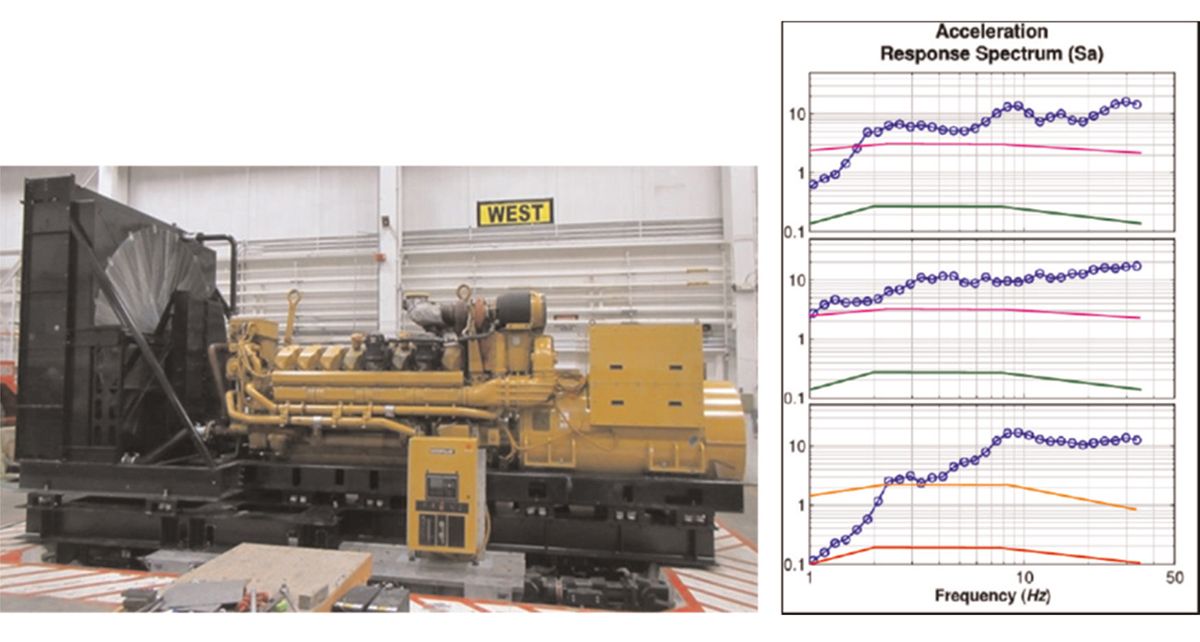

A significant new requirement was the anticipated flood level higher than before. To meet this requirement it was decided to install the generator set and the fuel tank one meter above the initial installation level on support structures. These structures had to be designed to the anticipated seismic levels. Seismic qualification of the tank and the generator set became more challenging. Introducing flood elevation structures left less space for the equipment in a given building. Only due to its increased power density versus the removed generator set it was possible to fit the generator sets into the existing building on flood protection structures. Otherwise a new building or more complex means of flood protection might have been necessary.

During the entire project period, the operator used rental generator sets at significant cost. These rental sets did not have any nuclear certification, so that for more than two years the nuclear power plant operated in an exceptional mode from a regulatory point of view.

From the start of the installation of the new equipment, the scheduled completion date started to move, resulting in a project duration of more than two and a half years and respective cost increases.

CASE STUDY 2 – DUKOVANY & TEMELIN

Dukovany and Temelin NPPs in the Czech Republic were designed and built in the 1970s and 1980s with Russian reactor types and plant design. Dukovany NPP has four VVER440 reactors, with 500 MW electrical output each. Temelin NPP is equipped with two reactors, type VVER1000 with 1080 MW each.

These plants originally had three emergency Diesel generators (EDGs) per reactor, level 2 (for definition, please refer to chapter 6) without any additional layer of safety. The post Fukushima stress analysis revealed weaknesses of this concept, and authorities mandated the addition of two generator sets per power plant. Each generator set was sized to replace one of the existing EDGs. Various safety related requirements included:

- Complete independence from any other equipment in the NPP, especially the existing Diesel generator sets

- 50 years of service life

- From start to 100% load in less than one minute

- Fuel tank for eight hours operation

- Battery starting

- 3200 kW output, 6.3 kV

The new installation also had to be designed to resist electromagnetic impact, explosion shock wave, extreme temperatures (both high and low), extreme wind speeds and precipitation, and impact from flying objects, such as debris carried by a hurricane or parts of the cooling towers that could drop during an earthquake.