Video transcript

00:00

Hello, I’m Simon Hill. I’m the Product Demonstrator at the Leicester Customer and Training Centre at the Caterpillar facility at Desford, Leicester, UK. Today we're going to be talking about the morning safety checks we do on the machines we have in the demo fleet. I've got a Compact Wheel Loader here as an example and the 302 Excavator so we can do tyres and tracks.

00:51

On the Compact Wheel Loader in the morning, I’ll walk around to it. Fortunately today it’s got nice dry ground conditions with gravel underneath. Taking a quick visual inspection, if you see any damp spots under the machine, that could be oil residue or coolant that's dripped off the machine overnight so that's a good indication there’s a problem there. I’m also looking around the tyres and checking for any cuts in the tyres, on the sidewalls and visually checking for inflation - I check these weekly anyway. On this machine, I run a little bit higher pressure in the front than I do the back, hence why the tyres have a little bit of squash to them. Overall, check the condition, make sure both the mirrors are okay; there’s nothing cracked on there and I’ve got no damage to the lenses. Looking at the front, check the condition of the quick coupler, make sure the hoses are okay and that there’s no visible signs of leaks, cracks or any damage to the coupler.

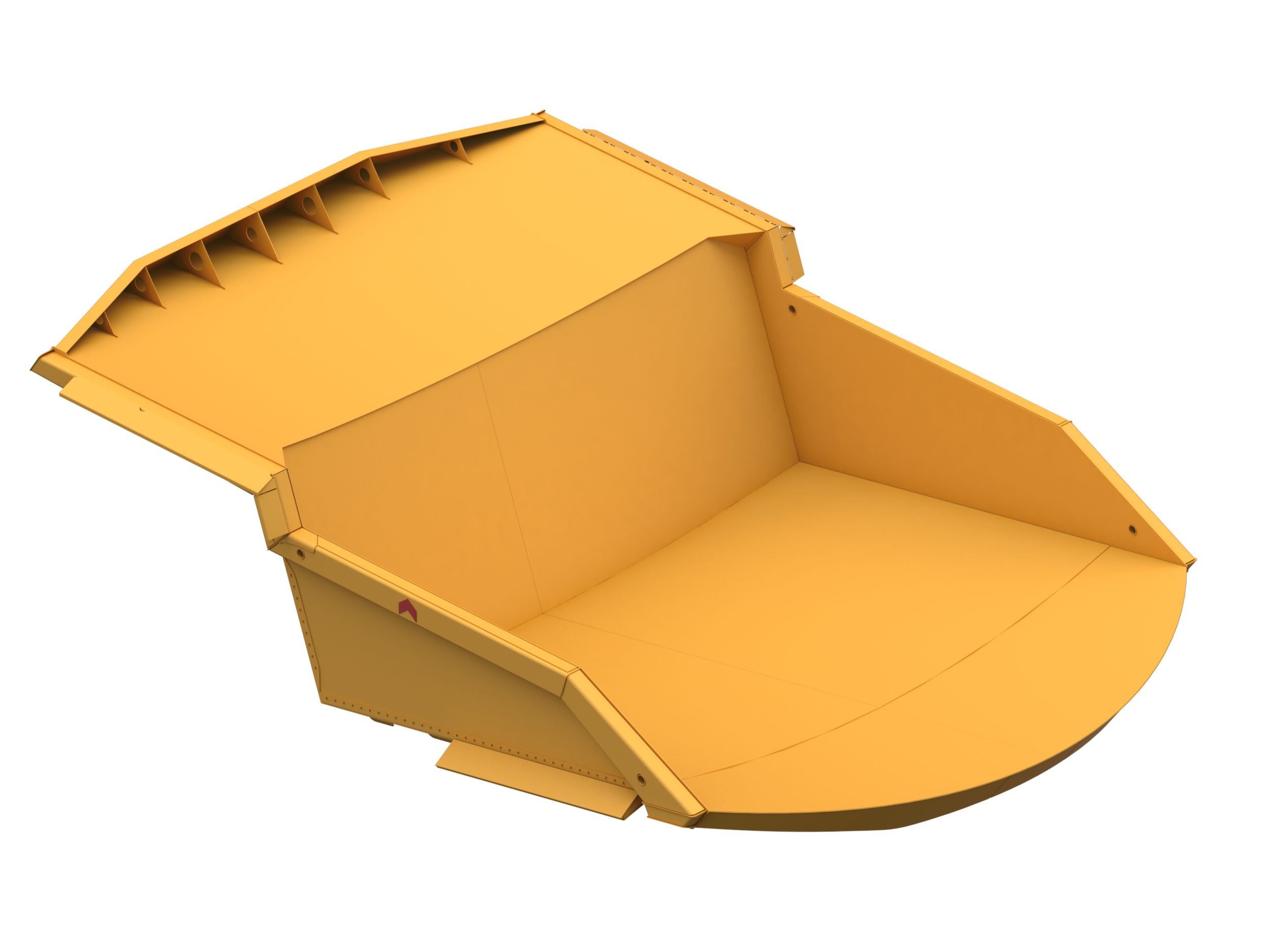

This bucket is fitted with a cutting edge so I can quickly look along. If any of the bolts holding the cutting edge on have come loose, you'll notice that the dirt falls off and you get a clean spot around them. These have all got dirt on there and they’re all tight. The cutting edge hasn’t got any cracks or signs of damage. Also, it’s good to check if your cutting edge has begun to wear; it may be time to turn it and spin it round. With a lot of the Cat attachments you can reverse the cutting edge to get extra life out of it.

02:26

Round to the rear of the machine. Now checking the engine bay of this machine. Currently in the UK it’s springtime and these machines have been stood over the weekend. It’s very good this time of the year to visually inspect for any signs of birds’ nests. The other day, for example, I checked the 308 E2 we have which is been stood for a period of time, lifted the engine bay covers and there sure enough there was a bird’s nest that started to be formed where the DPF is. I checked, there were no signs of eggs or any birds actively nesting so I managed to remove it. That would have led to a fire or possible thermal event if I hadn’t have cleared that out the way so check around there and look for any signs of twigs or nesting materials. This machine is nice and clear.

While I’m under here, I would check the oils and fluid levels. On here I've got my hydraulic tank site gauge, screen wash, coolant reservoir, some within the lines on the coolant reservoir, dipsticks down here so I check that with a cloth, clean it, make sure that’s okay. Looking around in the belly of the machine, check there's no residue in there which is a chance there could be a leak in an area that I can't easily get access to. Around here everything seems to be clean and in good condition. Any hoses you can get to, just give them a bit of a push make sure they’re tight and everything’s okay; everything seems fine there.

On this machine as well you’ve got an access door, so if I lift this handle, that has now pulled the radiators apart. This has got a hinged radiator cooling pack. We’ll go around the side here and I can now visually inspect. I can see that the core is okay and there’s no build-up of leaf material debris that could lead to overheating so that’s nice and clear. Let’s push this handle back, that’s okay. Check the lights, make sure they’re okay. The lenses are all okay. Normally I would get in from doing any work in the evening and then in the morning turn the ignition on, activate the lights and check that all the bulbs are working okay.

04:39

In the cab of the machine, fortunately, on the Compact Wheel Loader it’s got two doors and everything is at ground level. So, if it's wetter conditions or I’m getting a bit of build-up of mud or dry mud has fallen off my boots and begun to build up on the mat, I’ll get a brush in here and sweep it out, clear it out. You want to keep your pedals clear and don’t want anything loose in here. If you can, put any of your personal items in the storage compartment here as you don't want anything falling down. Luckily on this machine there’s a nice large storage box where I’ll put my lunch bag.

05:12

Now moving over to the Mini Ex. Same thing, look around the ground there as any damp patches on the floor could indicate we've got a leak or slight weep that could lead to a leak further on in the day. A small problem can quickly lead to downtime on the machine if not rectified. Luckily there's nothing there. Tracks, luckily it’s nice and dry so the track frames are nice and clean so try and keep that clear if you don't want that packing with mud; it could lead to the tracks being over tensioned which can cause you problems. For track tension, I would bring the boom round and lift one side of the track up and then in the OMM it will tell you because each machine has a different measurement for the gap required between the rack and the bottom rollers.

Now another thing to point out, if you look at this rubber track there’s a mark here which is the infinity mark. If you have that central, so central to the track frame, that’s going to be the lowest, saggiest part of the track because that’s where the bands in the track overlap so it’s the heaviest part of the track. That’s going to be where you get the saggiest point so that’s going to be the low point if the tracks are under tensioned. The infinity mark is here. If the tracks require tension, get a spanner, remove this cover and then here’s a grease nipple so I’ll put the grease gun onto there, add grease that will send the piston out on the idler which will tension the track. Now, it’s imperative that you keep it to the correct tension. Some operators say ‘oh I’ll put a lot more grease in them than required, I’ll get the track tension up really tight and then I won’t have any problems’. The problem is then you’re going to start stretching the track which is going to lead to more problems down the line so only tension it to the correct measurement in the OMM.

Again, round the machine, this machine’s fitted with mirrors so check the condition of the mirrors, that they’re not cracked and have no problems with the lenses. Check that the pins are in, this has got an extending blade with wings so check the pins are in on here. Check the overall condition of the hoses, that there’s no oil residue running down the boom, that the tight cylinders are in good condition and there’s no damage to the chrome on the cylinders and the quick connects are okay. And then the quick coupler - this one is a twin lock system with a cam at the back so I’m just checking. Also, check the bucket on here, making sure the clips are in for the bucket pins. Bucket teeth, again, the same with what I said with the Compact Wheel Loader, normally if you’ve got a loose tooth on your bucket you’ll see that there’s no dirt or debris around the bolts because the bucket tooth has been moving and keeping it clear. This one, there’s a nice layer of dirt round there and I can physically check that they’re all tight.

Now luckily on the Next Gen Mini Excavators, we have a nice easy access side panel so I can check the radiator core here, checking for signs of any residue, nothing there. Screen wash is full, exhaust there as well, no problem there, all the brackets are tight, no signs of cracking. And moving around the back, open the engine bay. If it’s a windy day there’s a little stay on here so I’ll put that in to stop that whipping around on me. My hydrate tank gauge is here, I can check my oil level, fuel water separator and then again round here I’ll check the oil level and engine oil level. Because it’s nice and dry at the moment, we’ve got the air cleaner, engine air cleaner here. There’s a little rubber bung on the top so you get a little pinch and get rid of any build-up of debris that is in there.

09:02

Now that was just a quick video walk around, showing what I do on the machines on a daily basis. Some good tips there. If you always check your machine first thing in the morning, you’re not going to get any surprises throughout the day, that’s what I find, and it helps reduce downtime. So, I hope you found this video informative. Look forward to seeing you in the next one.