Video transcript

0:04

Hello, I'm Simon Hill. I'm the product demonstrator at the Leicester Customer and Training Centre. Today we're going to be looking at the Caterpillar 306 Next Gen Excavator, and this one is fitted with the TRS6 Tilt Rotator. Now on this Tilt Rotator, we've got an S40 bottom hitch, and we've got the Caterpillar top hitch.

0:38

If you have a 308 Next Gen Excavator or a 309, you can then fit that with a TRS8 Tilt Rotate System. Again, it gives you a variety of options for bottom hitch and top hitch, either direct mount, or choice and S-type coupler or Caterpillar coupler on the top. And that's an S50, pick up at the bottom.

0:57

So the specification for this 306 Next Gen. It has a 6.4 to 7.1 tonne operating weight, depending on the configuration of the machine and a 55 horsepower, or 42 kilowatt Cat c 2.4 engine. You've got a 3.7-metre standard dig depth or 4.1 if you have the long dig-depth stick. It has 3.7 tonnes lift capacity at three metres of reach, or 1.5 tonnes lift capacity at full reach with the blade down.

01:29

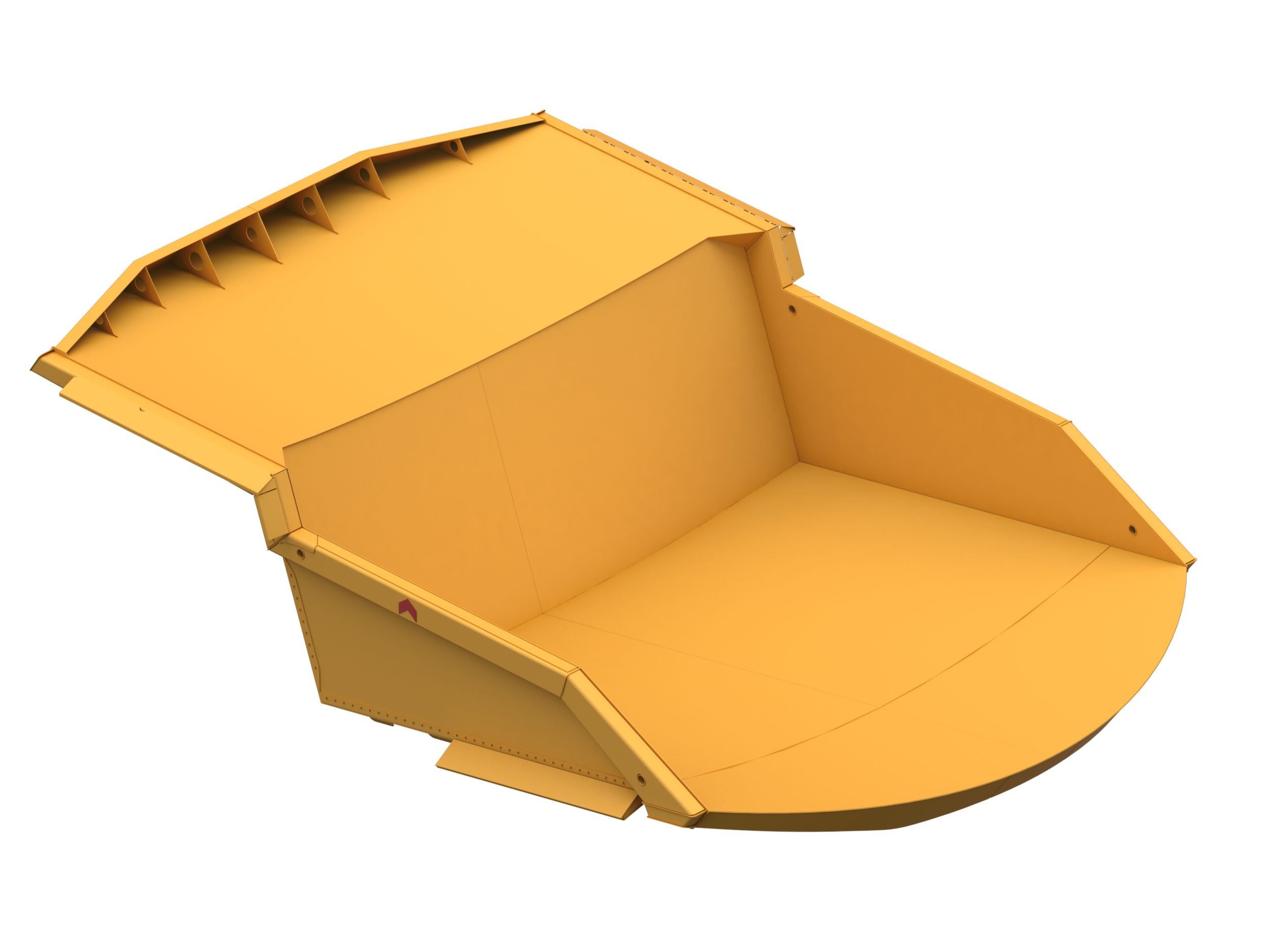

One piece of advice for anybody choosing a Tilt Rotating System on their excavator whether it be a 306, or a 308, is please select the additional counterweight. If you have that from factory, it is a lot better for the machine, it will offset the extra weight of the Tilt Rotator and bucket on the front.

Another consideration to make is the stick length that you want to have. If you have the standard stick that will be more than sufficient in fitting the Tilt Rotator because you've got the extra length here with the top hitch and bottom hitch. If you fit this to a long stick machine just bear in mind, you are gaining this nearly a foot and a half, extra length. So, at maximum reach you will have a little bit more weight. Yes, you're going to have the advantage of the extra reach it gives you, but for over the side of the tracks just bear in mind stability. So, a standard stick is more than suitable for this type of setup. This is the long stick. And we just have to bear in mind when working over the side of the machine the extra weight that this can give with this bucket full.

02:36

So, on this 306 excavator we've got the optional eight-inch touchscreen display. So on here you've got a really good rear view camera screen. You've got your gauges, fuel, speaker volume for the radio and temperature and H back units. You can quickly access these with the shortcut buttons down here. And then you can just touch the screen - speed the fan up, slow the fan down, increase or decrease the temperature. Turn it off, put the air conditioning system on. So with the shortcut buttons, it does make things a lot easier, you're not having to scroll through, touching the screen randomly.

Down here we've got the icon for the Tilt Rotator System, so by pressing this now, I've now got the sub menu for the Tilt Rotator, this is showing the angles that I've currently got set on the Rotator. If I'm doing a job, such as trimming stone out, putting a roadway in, I can then use the homestore button. I can click this and this will copy the values from this side. I can then go from trimming stone out to shaping the sides of banking or a ditch, quickly press this button here, and that will send the bucket back to the stored values which are on this side of the screen.

4:01

Also in here by going through the menu system, I can now select machine settings. I go to work tool. I then go to the Tilt Rotator screen. You've got a choice of other options. So, I can change the aggressiveness of the bucket shaker which I can show you later, just by using the sliders as such. You can then change - some operators on the rollers, each operator has different ways of approaching this, I've set it up how I find it easier. So, for example on this joystick, if I rotate the roller to the left, the bucket rotates the left, if I do it to the right the, the bucket rotates to the right.

On this side, I've got the same for the tilt. If I roll, push the roller to the right, the bucket tilts the right, left it tilts to the left. Some operators like to have this inverted, so they'll roll the roller left but the bucket will kick up to the right. It does make it sometimes easier when the bucket’s in the reverse configuration because it moves more intuitively to how you'd expect it to but I personally prefer it the other way around. If you want to change any of that you can go in here: machine settings again. Let's go to work tool. Go to Tilt Rotator. So you can go to roller invert, and then you can invert whichever ones you want: left thumb, left finger roller, right thumb roller, right finger roller.

5:28

And again, you've got speed limits as well. I've got everything set to 100% because I'm quite happy with it in a fast operation. If you want to slow things down, if you are doing some delicate work around services, again you can adjust these, so you can adjust your rotate speed. You can then adjust your tilt speed. And then you've got the extras for the extra function on the buttons if there's a programme.

5:59

Back to performance, this is now showing us the main menu, the values that are still stored in there.

6:53

So, one feature that the TRS6 and the TRS8 have, is that we have bucket shake function. So, with the bucket shaker, I can use my thumb on this round button here, nearest my knee. I hold that in, and then using the roller for the tilt function.If I now apply tilt function, you'll see the bucket shake.

Very useful for pouring gravel, sand into footings. Even if you wanted to pour concrete.

You can now shake that material out nicely and controlled.

And using the settings I explained about earlier, you can change the frequency that the bucket shaker shakes at. Also very good if you've been working in sticky material, green clay for example, you can shake that out the bucket so you're always remaining with a nice clean bucket, ready for your next pass.

8:06

So another good feature on the TRS6, and for that matter the TRS8, is the home button. So, this icon down here, you’ve got the house and the bucket. So that's the home position. So if I wanted to record the position of bucket as it is now flat on the floor, I push and hold that, already done it before hand, and then you'll see look that these positions now are mirrored on the second screen. Where that comes into its own is, if I want to grade the bank up now,

So I'm going to slew across, adjust my bucket.

8:41

I'm going to pull the bank up.

8:52

Then I quickly want to revert back to the other position I had it at

09:00

If I come round now, and just press this button here with my thumb.

9:09

That's now back in that position. One degree out but hey ho. So that's a very useful feature it, makes you more productive, particularly useful for grading out trimming stone out so for example,

9:25

I want my bucket level, for trimming the stone out. Push and hold that now. See the values have gone over. I could then be doing some batter work, sloping the batter up

9:40

Tidy that up

9:43

For example

9:50

One thing to bear in mind it does not adjust the bucket tilt cylinder, so you have to make sure you put that in the similar position it was in before, but it does control the cylinders on the Tilt Rotator. So push and hold that button now, see it's come back around. Ready for trimming the stone out again, so real useful feature there.

Well I hope you found this short video on the Cat 306 and TRS6 Tilt Rotator System informative. We look forward to doing some more short videos in the near future. Thank you.