- Daily maintenance areas are easily accessible through large service doors and a power hood with walk-in access to the engine compartment

- Track components do not require routine maintenance and easy to replace track pads help lower service costs

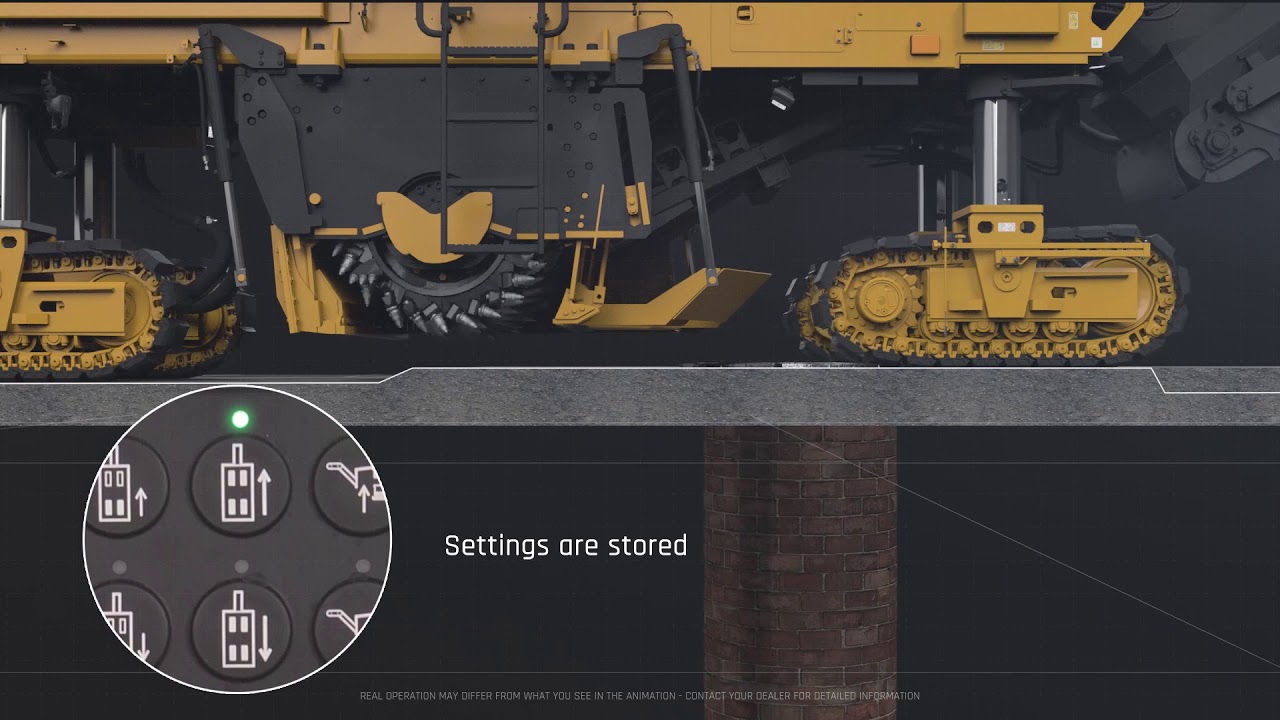

- Standard ground-level controls and an optional hydraulically-operated rotor turning device with pendant simplify bit removal and replacement

- High and low pressure washdown options connect to the onboard water tank for convenient clean-up

- The accessory drive system allows use of select machine functions when the engine is off

- Electrical system wiring is color-coded and numbered for easy identification and wrapped in a protective, abrasion-resistant nylon braid for longer life

- Monitor fluid conditions with regular sampling to help extend change intervals up to 500 hours engine oil, 6000 hours hydraulic oil and 12000 hours coolant

- Built-in diagnostics monitor machine systems, alert the operator of performance issues and provide troubleshooting information

- VisionLink takes the guesswork out of managing your entire fleet–regardless of size or equipment manufacturer*–by providing maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes, and more through interactive dashboards on your mobile device or desktop, helping you make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite

- Remote Flash allows you to update onboard software without a technician being present, allowing you to initiate software updates when convenient to help increase your overall operating efficiency**

- Remote Troubleshoot allows your Cat dealer to perform diagnostic testing on your connected machine remotely**

- Cat Inspect is a mobile application that allows you to easily perform digital preventative maintenance checks, inspections, and daily walkarounds

- Convenient parts availability, dealer locations and service repair kits simplify ordering of high wear components

* Data field availability can vary by equipment manufacturer and is provided through an application programming interface (API).

** Must be within cell range coverage.