Customer: Altos Hornos de Mexico (AHMSA)

Location: Monclova, Coahuila, Mexico

Customer Business Issue: Lowering electricity costs and emissions with a reliable energy-efficient solution

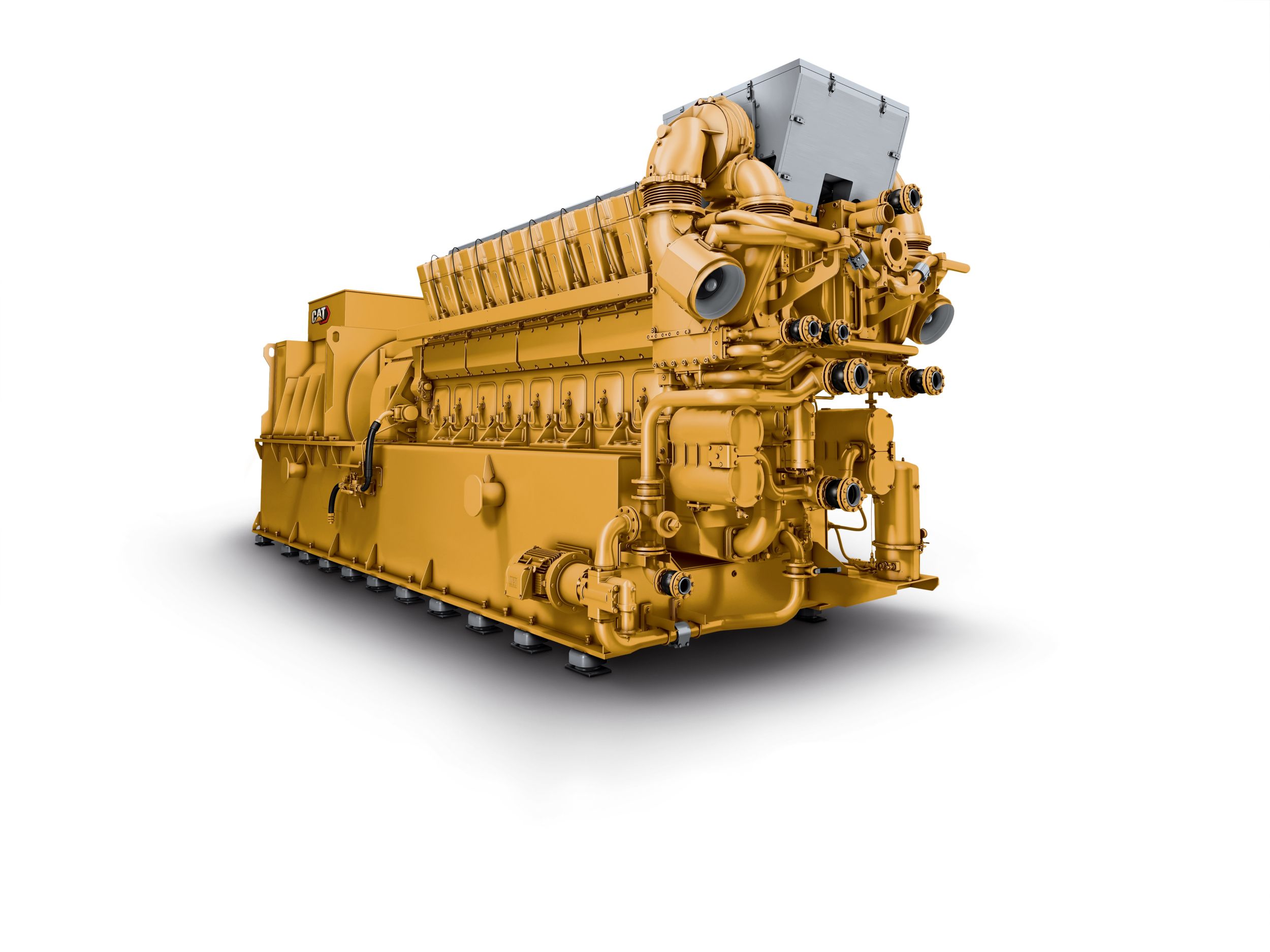

Solution: 40 Cat® CG260 generator sets

Cat® Dealer: MADISA

In the highly competitive steelmaking industry, enhancing operational excellence is critical to a company’s survival. With the constant pressures of consolidation and environmental regulations, steel companies must maintain a higher level of quality and efficiency in all operations.

Steel companies have responded to these challenges by improving plants, equipment and technology to increase production and responsiveness to customer needs, while reducing costs.

AHMSA, Mexico’s largest integrated steelmaking company, manages every aspect of steelmaking, from mining to manufacturing. Located in Monclova in the state of Coahuila, AHMSA has a workforce of 21,000 people and produces 5 million metric tons of liquid steel annually. The company mainly produces flat steel products like hot- and cold-rolled coil used for machinery parts, railroad tanks and bridge construction, as well as structural shapes used in a wide range of manufacturing segments.

“We face many challenges in the steelmaking industry, and one of the greatest is energy consumption and its cost,” said Emigdio Valades, power plant area superintendent for AHMSA.

AHMSA consumes more than 400 MW of power between its two steel mills. In order to reduce overall operating costs, AHMSA needed to develop a more cost-effective source of power to keep its mills running.

AHMSA implemented a plan to generate 160 MW of power from four separate plants powered by a total of 40 Cat CG260-16 generator sets.

With the help of local Cat dealer MADISA, AHMSA opened the first of the four plants in April 2014. MADISA designed, engineered and constructed the plant, called Planta de Fuerza No. 7 (PF7), as well as trained AHMSA employees in the operation of the plant. PF7 is considered the largest Cat gas-powered project dedicated to continuous operation in the Americas.

To fund the project since the construction of the power plant, AHMSA and MADISA utilized the services provided by Cat Power Finance, a division of Cat Financial specializing in financing turnkey power generation projects, such as PF7.

“We want to be close to our customers to understand their needs and offer them integrated solutions,” explained Edson Hernandez, energy business manager for MADISA. “We look for a better solution in accordance with our clients’ needs and complement it with product support as part of a long-term commitment.”

Ten of the 40 Cat CG260-16 generators reside at PF7. The CG line of gas-powered generators is extremely versatile and can be tailored to a specific site, while offering low operating costs, reliability and integrated solutions.

A multivariable control integrates all critical control functions on the engine, improving dynamic load response and electrical efficiency. The CG generators also use 40 percent less oil than most competitors, saving 4,000 liters (1,056 gallons) of oil each year.

“We chose the CG260-16 because of its innovative technology, operational flexibility and the output – as well as the efficiency, which is very high for this kind of engine,” said Carlos Garcia, AHMSA’s project manager. “At the moment, we are operating at a very high capacity, which is highly acceptable for a brand-new plant.”

The CG260-16 generators have an extremely high electrical fuel efficiency rate on site and produce 40 MW of power at PF7. For AHMSA, this means having a reliable energy supply with significant savings in electricity cost as compared to the supply offered by the main utility supplier in Mexico.

Due to the significant energy cost savings from PF7, the second of the four proposed plants is scheduled to open by December 2015. The reduction of energy costs and the partnership with MADISA and Cat Financial allows AHMSA to focus more of its capital on growing its business and manufacturing high-quality steel products.

“The parts and service support we receive from MADISA is excellent,” added Jorge Rodriguez, superintendent of PF7. “If there is any sort of issue, we can expect a rapid response. MADISA continues to be our advisor on this project, working closely with us to operate PF7, and we will rely on them in the future as the rest of our plants open.”

From natural gas-fueled combined heat and power (CHP) systems and emergency power for facilities, to renewable biogas energy to support the local grid, or electricity generated from coal mine gases, Caterpillar has a wide range of reliable gas power solutions.

Learn More