Modern landfills are required to install gas collection systems to capture and destroy the methane gases that are naturally produced within a landfill. These gases are burned in a flare. Rather than eliminating landfill gas by simply burning it off, Caterpillar can help you turn it into a renewable fuel by providing methane generators that can produce electric power from landfill gas.

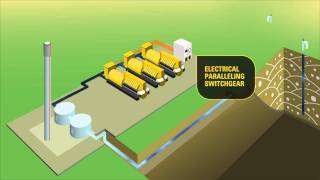

Landfill gas is produced naturally as organic waste decomposes in landfills. It is composed of methane, carbon dioxide, and small amounts of non-methane organic compounds. As an important and growing application within the world's power generation mix, landfill-gas-to-energy systems collect, process, and treat this gas for use in generating electricity. Two common approaches to landfill gas collection include vertical well extraction and horizontal collectors or trenches.

Municipalities generally use blowers or vacuums to direct the gas from a collection site through a network of pipes to a central facility. At most developed municipal solid-waste landfills, the methane and carbon dioxide are destroyed in a gas collection and control system or utility flare. The sustainable alternative is to divert the landfill gas from the flare to be used in electricity-producing Cat methane generators.

The diverted fuel is dried and sometimes refined to remove impurities such as:

After fuel treatment, the methane is introduced into a Cat gas generator as fuel. These generators are specifically designed for operation at landfills with:

Cat switchgear with PLC-based controls is supplied to parallel the generators to the local electrical grid to export renewable power at a premium to the local electric utility.

Hangzhou Municipal Solid Waste Treatment Company Ltd. operates multiple landfills in Hangzhou, China. The two landfill power plants currently export approximately 4 MW of electricity back to the local grid, enough to power 20,000 average Chinese homes. Through Customer Support Agreements with the developers, Cat dealer Lei Shing Hong has kept the generators running smoothly, helping contribute to the increased reliability of the local power grid.

Learn MoreBased in Plymouth, Indiana, Homestead Dairy has 1,800 milking cows and 1,700 cows come in from three nearby facilities for milking. Continued success increased cow manure and the odor was directly impacting the nearby residents. They decided to build a biomass waste-to-energy facility to convert the manure into electric power and Homestead Dairy partnered with local Cat dealer, Michigan Cat, to customize a green energy power generation system.

Learn MoreEnerdyne Power Systems is one of the most experienced landfill gas-to-energy developers on the East Coast. Municipalities and landfill management companies that partner with Enerdyne do so to be proactive within the community in terms of reducing harmful landfill gas emissions.

Learn MoreThe transformation of domestic waste into a valuable commercial product is a necessity today. The power plant project is expected to improve methane gas ventilation at the landfill site, while providing an environmentally friendly fuel source to generate electricity. The power plant has resulted in social ecological and economic benefits for the customer.

Learn MoreCaterpillar is leading the power generation marketplace with Fast Response generator sets engineered to deliver unmatched performance, reliability, and cost-effectiveness.

Learn MoreFrom low energy gas-fueled combined heat and power (CHP) systems and emergency power for facilities, to renewable biogas energy to support the local grid, or electricity generated from coal mine gases, Caterpillar has a wide range of reliable gas power solutions.

Learn MoreFrom natural gas to biogas, coal mine gases, or hydrogen fuel blends to support combined heat and power (CHP), emergency power, and local grid support applications, Caterpillar has a wide range of reliable gas power solutions.

Learn More