If you already have an existing account with another Cat App, you can use the same account to sign in here.

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

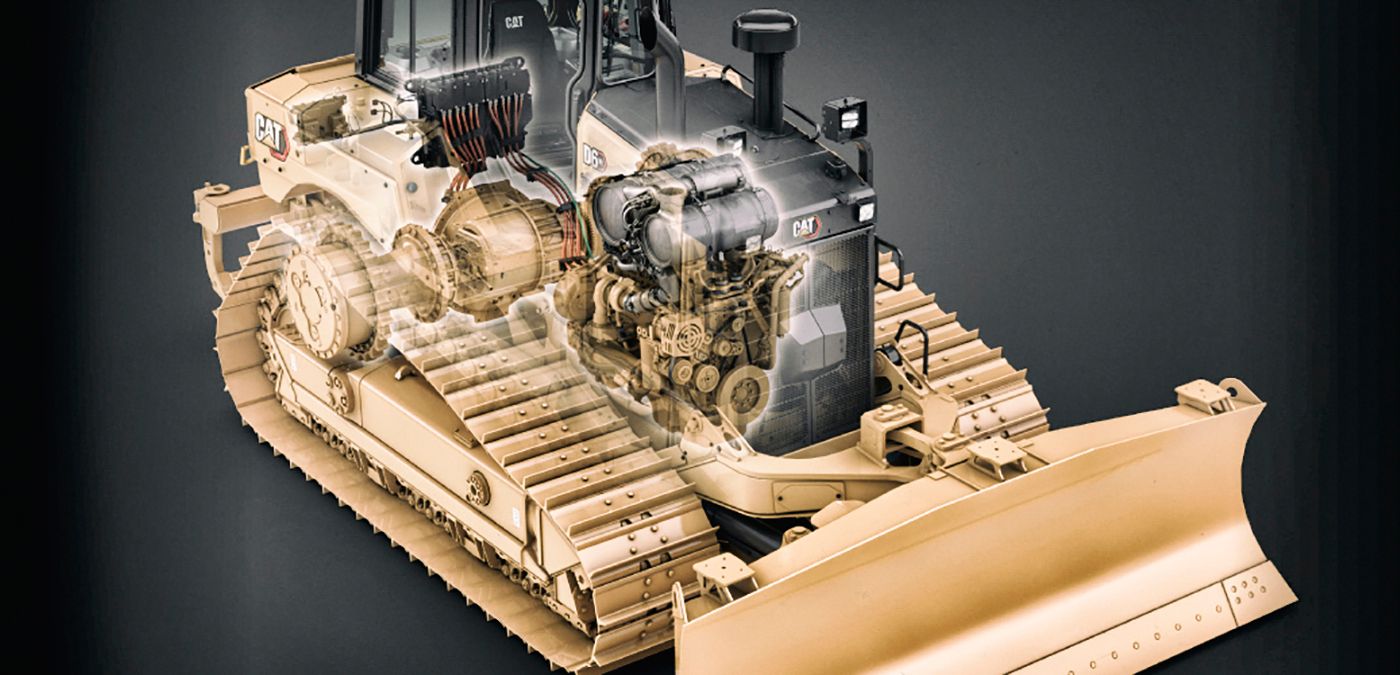

CHOICES, CHOICES: ELECTRIC DRIVE, AUTOSHIFT OR TRADITIONAL POWERSHIFT?

Just when you get used to the idea of automatic shifting, heavy equipment manufacturers go and throw another option at you: electric drive. If you’re unclear about the differences — and the reasons why you’d choose one or the other versus a traditional powershift transmission — you’re not alone. We’ve got answers to some common questions.

How does electric drive work?

Instead of powering a torque converter, the engine drives a generator that turns mechanical engine power into electricity. And instead of a transmission, an electric motor powers the final drives. A power inverter is connected to both the generator and the motor by heavy-duty power cables and connectors, and this inverter controls the flow of electricity between the two components. The electric motor can operate at all ground speeds, ensuring the machine is always working at the most efficient point possible.

What are the advantages of electric drive?

Higher levels of efficiency — both operational and fuel efficiency — are the biggest benefits. Electric drive systems achieve most of these gains by allowing the engine to work consistently within a narrow speed range. The continuously variable electric drivetrain can vary torque delivery to the final drives with minimal change to engine speed. That lets the engine work within its most efficient speed range, which reduces fuel consumption and can extend engine life.

How do new powertrain options compare to traditional transmissions?

Let’s take a look at one dozer model that comes with both electric drive and automatic shifting options to see the differences:

The next generation Cat® D6 XE is an electric drive model. Although you’ll invest more upfront, your fuel savings may reach as high as 35% compared to the previous three-speed D6T Dozer. There are no gears to shift, with power to the ground continuously optimized for forward momentum throughout the push. The combination of constant power to the ground, continuous push and greater maneuverability means faster cycle times. And because electric drive has 90% fewer moving parts than a traditional powershift transmission, it’s a simpler system that reduces your maintenance costs. If you’re working this dozer hard, you can expect to earn back that initial investment in two years or less.

The Cat D6 comes with a four-speed, fully automatic transmission. It’s a lower investment than the XE model, but still delivers significant fuel savings — up to a 20% improvement in fuel efficiency over the D6T. Fully automatic shifting with an added transmission gear reduces the momentary hesitation felt when a traditional machine shifts. More momentum and drawbar power are maintained throughout the entire push. Auto shift works up and down the entire working range, too, so power to the ground and fuel consumption are optimized for a greater percentage of the time.

When would I choose electric drive versus automatic shifting?

It all comes down to your application and your goals. Both power trains are easy to operate with no worries about shifting. The operator simply sets the ground speed, and the dozer automatically optimizes based on load for the greatest productivity and fuel efficiency. However, if your job demands the highest level of productivity AND significantly lower fuel consumption, electric drive may be the way to go. Your Cat dealer can help you weigh your options and make the best choice for your operation.

RELATED ARTICLES

You’re here to get ideas to grow your business. Read on for machine insights and expert tips and tricks to get more out of every job.

-

Get Started By Selecting and Configuring Machines With Technology

Technology is an investment, so it makes sense to take your time and not just jump in.

Learn More -

Quick Wins That Realize The Rapid Profit Power Of Machine Data

Once Product Link is activated, all you need to do is set up your VisionLink account and start taking a look at what your machine information can tell you.

Learn More -

Win More Work With Cat Grade Technology

It’s quickly reaching the point where you may not be competitive without grade control or technology.

Learn More -

Cab Technology Helps Boost Productivity

New cab technology in your Cat machine is designed to help you be more productive, work more efficiently and be less fatigued.

Learn More