If you already have an existing account with another Cat App, you can use the same account to sign in here.

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

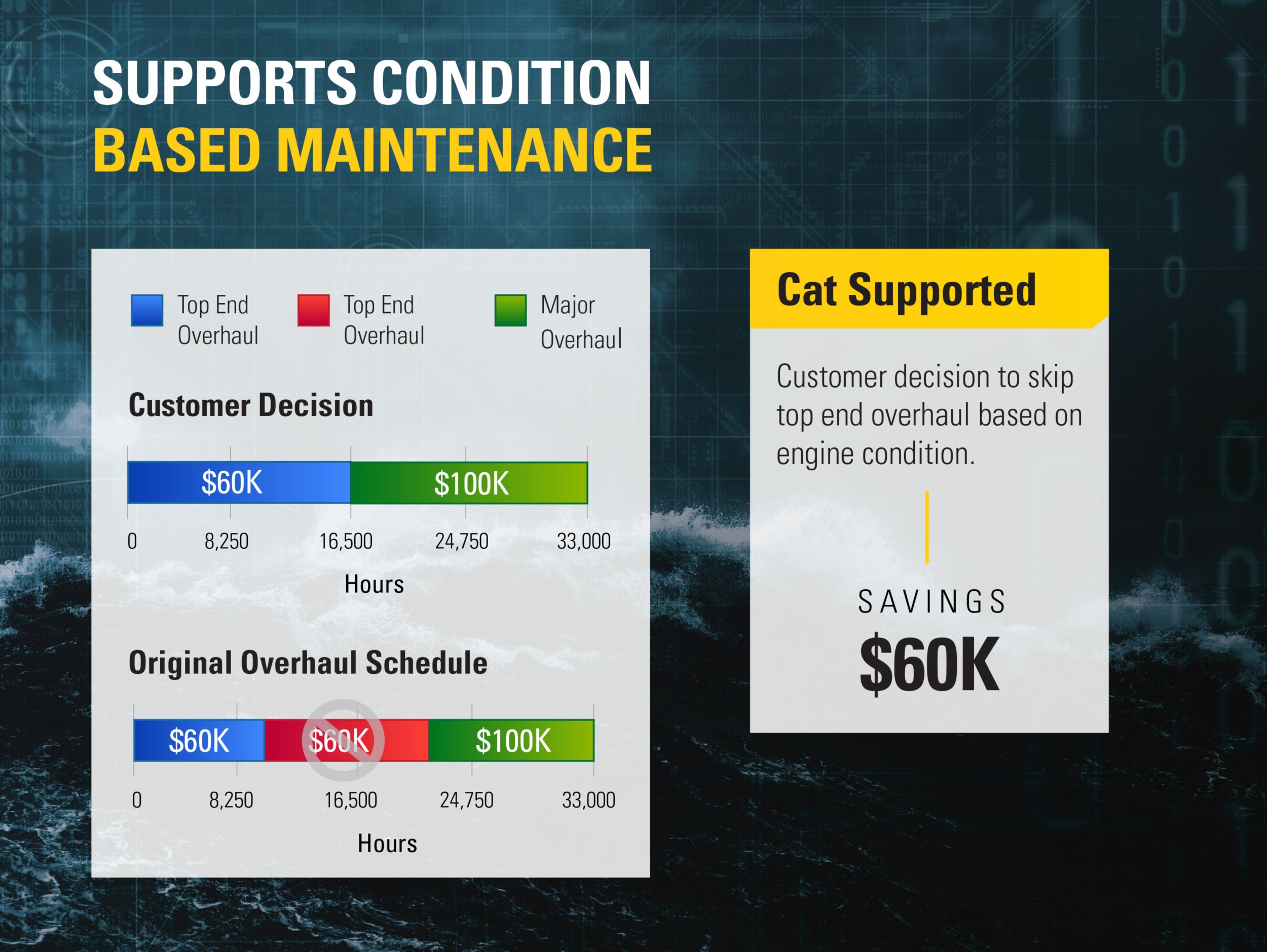

Condition-Based Maintenance Extends Intervals And Saves $60K

What happened?

An offshore oil rig uses Caterpillar Advanced Condition Monitoring (ACM) — which gathers data in real time and analyzes it 24/7 — and the services of a Cat® Fleet Advisor to monitor its five Cat 3516C diesel generator sets. The customer decided to extend maintenance intervals for the units beyond 11,000 hours, the typical timeframe for a first overhaul. When service hours topped 16,000 hours, the Fleet Advisor recommended waiting no longer to perform the repair to reduce the risk of catastrophic failure.

What is the underlying cause?

Knowing that the Cat Fleet Advisor was using ACM tools in conjunction with electronics, oil analysis and site inspection data to keep an eye out for any potential issues and make recommendations to prevent failure, the customer felt confident extending the time to first overhaul.

What is the value to the customer?

The recommended maintenance intervals for these engines are 11,000 hours for the first top-end overhaul, 22,000 hours for the second top-end overhaul and 33,000 hours for a major overhaul. By extending the first top-end overhaul until 16,000+ hours, the customer likely will be able to skip the second of the three overhauls — a savings of as much as $60,000.