Almost two years ago a Swedish designer, Fredrik Ausinsch, received a fair amount of press attention for an invention that seemed the dream of a science fiction novelist (a green, “woke,” sci fi novelist anyway): a yacht that could harvest algae from the waters of the Baltic and use the algae to power itself. This was the ultimate in biofuels: akin to the creation of a lawnmower that runs on grass clippings.

Ausinsch’s “sea harvester” was displayed at Dubai Design Week in October 2016.

Disappointingly, and despite the use of the term “yacht” in some of that publicity, the device unveiled in Dubai wasn’t a yacht. It was a small remote-controlled sea-going drone: and although Ausinsch does believe that algae has a promise as a biofuel, his focus is more on cleaning the stuff out of the Baltic than on using it.

This is an example of a common phenomenon in the publicity accorded to biofuels, on land or sea (or in the air). The idea that “X would be nice” gives rise to the further idea that “Hurray! X has arrived,” even when the latter X is really a Y, not the ‘would be nice’ X at all. Humans beings are not, any time soon, going to be transporting ourselves at sea on yachts that run on the sea’s algae.

What is Real

In the real world, algae is the enemy of fuel, not its source. It can make itself manifest as a brown sludge on the filter: not a good thing!

More broadly, the answer to the question that serves as the title of this story is, in a word, “no.” That will not be advisable any time soon.

What is real, though -- what is by now in fact old hat -- is “biodiesel,” a term that refers by definition to the use of processed (specifically esterified) fats or oils as a biologically created blending component with old-fashioned petroleum diesel. The most common mixtures range from B5 to B20, meaning that the fossil fuel stuff continues to provide from a high of 95% to a low of 80% of the volume of the whole.

In the US, and in much of Europe, diesel can be sold without any labeling as ‘bio’ if the bio portion is 5% or less of the whole. In some parts of Europe labeling of mostly-diesel fuel as biofuel isn’t necessary until one gets up to B7 or higher. In the US, fuel labeling is required above B5.

B100 is available, but it has its drawbacks. At B100, the fuel has about 8% lower energy density than diesel. When the amount of biomass gets to or below B20, though, as the Cat manual on commercial diesel engine fuels (hereafter Cat manual) puts it, “the energy density difference from diesel fuels is not significant.”

Characteristics of the “Bio” Part of Biodiesel

Chemically, the Bio part is fatty acid methyl ester (FAME). Cat manual says, “Without the chemical processing referred to as esterification, the oils or fats are not suitable for use as fuel in compression ignition engines.” This is so because unprocessed oils and fat cannot burn readily as fuels, will leave deposits on surfaces if burned, and free fatty acids are mildly acidic, and their cumulative effect can eat at the metal with which they came into contact.

FAME is biodegradable. That isn’t a bug, it’s a feature. Unfortunately, that fact allows microorganisms to feed on it.

Another problem: biodiesel is a solvent. This is often a selling point. Biodiesel loosens deposits that may have built up in the engine over long periods of use. But it may also be a bug. After all: what happens to the loosened deposits? They may well show up clogging the filter.

Biodiesel can also attack some rubber components of the system, which may include fuel lines and fuel pump seals.

Most of these problems are matters of degree that become more pressing as the amount of biodiesel in the overall blend increases.

Biodiesel, Metals, and Ash

Biodiesel fuels may contain phosphorus, alkali, or alkaline metals. The alkaline metals include sodium, potassium, calcium, and magnesium. These metals can get into the fuel either from the natural properties of the feedstock or in its processing. Either way: when they are present in the engine during combustion, these metals form ash, and that ash can be a source of problems.

As the Cat Manual cautions, this ash “can affect the life and performance of aftertreatment emissions control devices and may cause the need for more frequent ash service intervals.”

Biodiesel fuels that contain these metals, even at the levels of concentration allowed by existing specifications, should not use a blend higher than B20 in engines with such aftertreatment devices.

The Crankcase

There is also the possibility, whatever the chemistry of a blend, that some fuel will find its way into the crankcase and end up diluting the lubricating oil. Over time this can add up, and the introduction of biological material into the lubrication can make a big difference for engine durability and longevity.

Biofuel dilution of the crankcase oil can appear to be a higher oxidation of the oil, since the oxygen molecules within biodiesel can’t be distinguished from actual oil oxidation.

So when an owner/user detects apparent higher oil oxidation and/or dilution, Caterpillar recommends the use of Cat S-O-S Services oil analysis when biodiesel grades below B20 are used, and that analysis is required when B20 or above is used.

Shelf Life

There is also the often lamented fact that fuel with FAME has a much shorter shelf life than fuel without (in this sense, the acronym may be surprisingly apt, “fame is fleeting.”)

A word on the underlying chemistry may help make the point vivid. Fatty wastes in general are susceptible to oxidation because they have carbon-carbon double bonds. When biodiesel is exposed to oxygen, the oxygen attaches itself to the “bis-allylic” site directly adjacent to the two double bonds, which starts an auto-oxidation chain reaction.

Oxidation is also enhanced by the esterification, because the ester chemical group contains two oxygen atoms. Cat Manual, “Due to the ester chemical group and the unsaturation, the oxidation stability of biodiesel fuels is typically lower than that of diesel fuel.”

The ASTM specifications for B100 and B20 address the issue of oxidation stability. This is why owners of the vessels using such fuels must be vigilant (the manual’s words again) ensuring that they “always purchase fuels that conform to or exceed the specifications” and that they follow all guidelines for storage and handling.

There are antioxidant additives that can minimize the degradation. Still, this is another problem that will likely keep the amount of biological material in most biofuel blends used on the water well short of 100% for a long period to come.

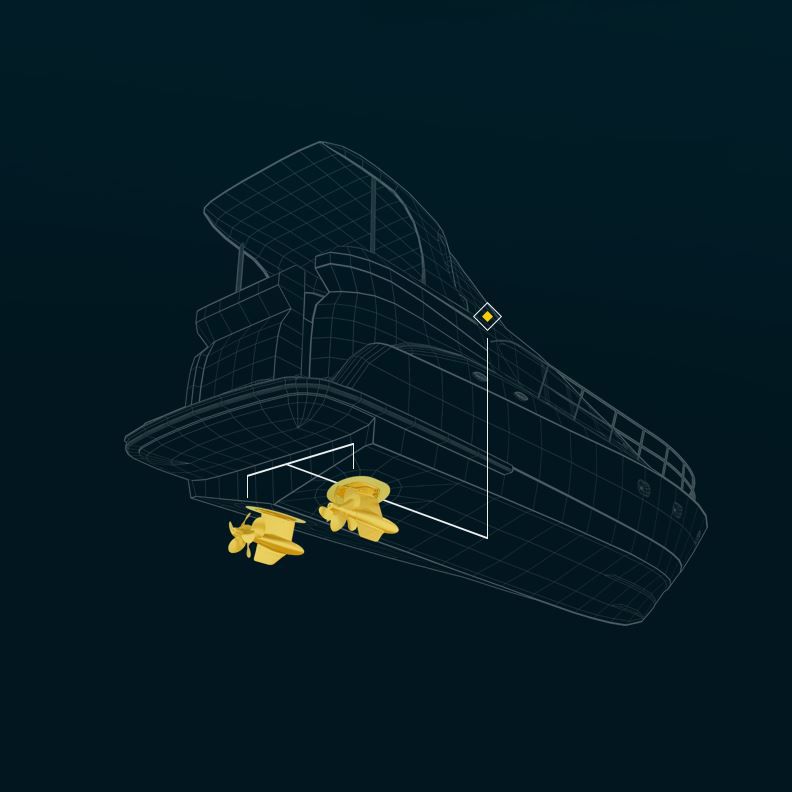

An engine’s fuel injectors, too, can suffer from wear and tear, leaving yachts and other affected vessels vulnerable to engine failure.

What is more, the proper working of the injectors for long periods requires that the fuel itself be lubricious. Lubricity varies with a number of factors, including the crude source whence the diesel was produced, the refining processes used, the handling of the fuel along the distribution chain, and the inclusion of additives.

Conclusion

But by way of a brief answer to the question with which we began … for most yachters, the answer to the question whether it is advisable to use B100 or “neat” biodiesel is: probably not.