If you associate the words “huff and puff” with the Three Little Pigs and the Big Bad Wolf, then you probably don’t know J-W Power Company and the gas compression packager’s innovative approach to maximizing the efficiency of an oil well.

A type of enhanced oil recovery (EOR), huff-and-puff technology involves injecting gas into oil-producing wells, then shutting those wells in to let the gas absorb the oil from the rock. After 30 to 45 days, wells are reopened and oil is produced to the surface. Energy companies use this technique to enhance total well production — recovering more oil than what’s possible through traditional methods — and J-W has found a way to help them do so more efficiently and economically.

The high-pressure people

J-W Power Company got its start in the late 1960s leasing compressor packages purchased from third parties and grew into one of the largest privately owned compression packagers in the United States, with a fleet approaching one million total horsepower. In 2011, the company was approached by an energy producer operating in the Eagle Ford Shale in South Texas for its expertise in high-pressure work.

“We build high-pressure gas lift (HPGL) packages to accelerate the initial production of wells, and we’ve been packaging compressed natural gas packages for high-pressure vehicle fueling since the 1990s,” says James Barr, Vice President of Sales for J-W Power Company. “It was a natural progression for us to move into high-pressure EOR.”

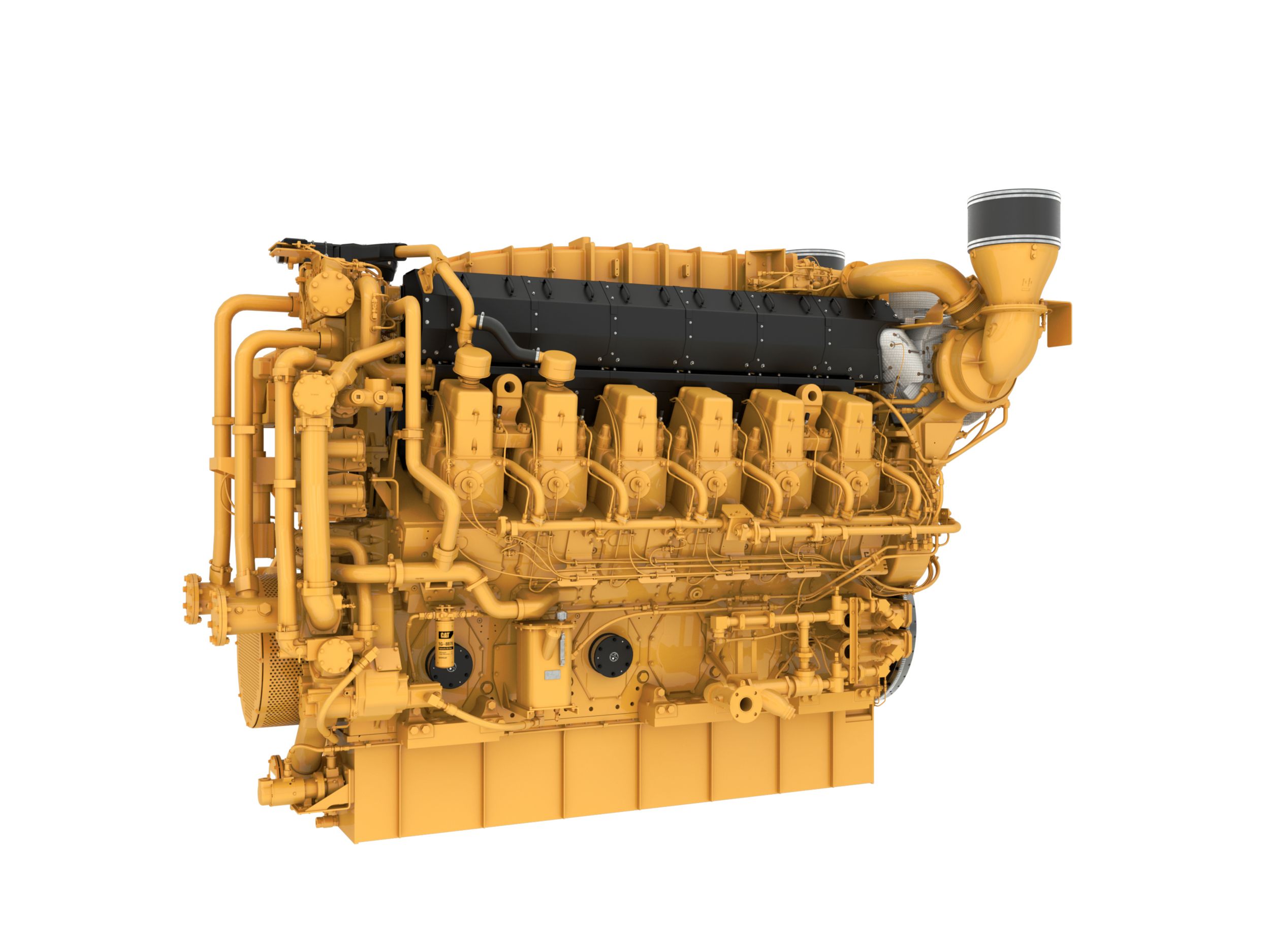

J-W Power Company’s first huff-and-puff project was a success, so the company quickly produced more than 50 packages featuring Cat® G3606 A3 engines and Ariel compressors for operations in the Eagle Ford and other shale plays. When G3606 A4 models were introduced in 2015, they became the staple of the package. Today, the solution is at work for approximately seven energy companies operating in three states — Oklahoma, New Mexico and Texas — with others in planning for North Dakota and Utah and dozens more expressing interest.

“We’re the only ones that have been successful on a large scale,” Barr says. “We’re known as the high-pressure people, and this package with Cat A4 engines can be deployed almost anywhere in the world to meet existing environmental regulations. It’s fuel flexible, portable, economical to operate and generates low emissions.”

Flexibility to use flare gas

A unique feature of huff-and-puff is that energy companies can inject their wells with gas native to the reservoir where they’re working. In other words, the gas they produce while drilling is the same gas they use to recover more oil. In areas like the Permian Basin, where that gas is typically flared — releasing greenhouse gas emissions — J-W’s solution offers companies a way to operate more sustainably.

Flare gas is “hot,” generally requiring conditioning in the field. The Cat A4 engines in J-W’s package, however, operate on a wide fuel band between 750 and 2300 BTU. That means energy companies can use their flare gas with little or no need for conditioning — making it an economical solution as well.

“An adequate fuel gas conditioner can cost a couple hundred thousand dollars,” Barr says. “Not having to buy or rent one is a big money-saver. The fuel flexibility of the A4 engines lends itself perfectly to these applications.”

“The Mother of All Compressors”

Barr jokes that one of J-W’s customers has nicknamed the huff-and-puff compressor package the “MOAC,” short for “Mother of All Compressors.” It’s easy to see why. It takes nine semi-trailers to haul the components to a site, and once it’s assembled, the total package weighs around 400,000 pounds. Still, it’s a portable unit — and that’s important because huff-and-puff doesn’t work for every well.

“Even within the same oilfield, you could have some wells that respond really well and others that don’t,” Barr says. “That’s the bonus of having the portability of the G3606 package. If a company has a well that doesn’t respond, then they can move it to another site.”

Four decades of Cat® power and support

J-W Power Company began packaging Cat engines in its gas compression offerings in the 1980s and never looked back. In fact, the company still has more than 20 packages in its fleet with Cat engines that date back to 1981. According to Barr, the Cat engine/Ariel compressor package is the industry standard for reliability, and it’s rare for J-W customers to request another combination.

“Our goal is to move gas for our customers and run 99.9% of the time, and Cat engines have served us well in meeting that goal,” he says. “But the big key is the support. The Caterpillar network, the way it’s structured, provides better field support and coverage. They always respond and do a good job.”

J-W primarily works with Holt Cat, the dealer that serves the company’s home base of Addison, Texas, and fabrication facility in Longview, Texas, but has also built relationships with other Cat dealers across the 17 states where its gas compression packages currently are deployed.

“All the dealers have been responsive, agreeing to stock parts and provide service for the engines when we move into a new area,” Barr says. “And Holt Cat has gone out of its way to support us, even traveling outside its territory to help out when the local dealer didn’t have natural gas engine expertise.”

That level of support extends beyond the dealer network to the entire Caterpillar enterprise.

“We started working with Cat Financial back in the late 1980s and still do today. They understand the oil and gas business, and our business as well, more than any other banking relationship we’ve had,” Barr says. “We’ve stood by Caterpillar for a long time, and we want to continue on that path.”