If you already have an existing account with another Cat App, you can use the same account to sign in here.

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Cat® Reman at 50: The People Who Make it Possible

Think you know Cat® Reman?

For 50 years, Cat Reman products have offered cost-effective, like new solutions for customers worldwide. And it took an enormous amount of dedication, innovation and grit to transform Cat Reman into the enterprise it is today.

So, let’s hear how it happened from some of the game-changers who helped define the product line.

WHAT IT’S ALL ABOUT

Meet father and son Steve and Jeff Stark. Their combined careers span Caterpillar’s involvement in remanufacturing, from the first facility in Bettendorf, Iowa, to the present flagship location in Corinth, Mississippi. As Jeff puts it, “I was born the same year as Cat Reman, so I’ve been around it all my life.”

They — along with Sergio Valdez Villarreal and Rosalinda Vazquez Aranda of the facility in Nuevo Laredo, Mexico — help tell our story. It’s a 50-year tale of materials recycled and parts remanufactured for generations of customers.

- JEFF STARK: salvage development technician; Corinth, Mississippi, U.S.

- STEVE STARK: retired, former technical resources manager; Jackson, Tennessee, U.S.

- SERGIO VALDEZ VILLARREAL: Lean Six Sigma Black Belt, Strategic Projects, Nuevo Laredo, Mexico

- ROSALINDA VAZQUEZ ARANDA: group manager 2; Cat Reman Global Operations, Nuevo Laredo, Mexico

HOW IT STARTED

Let’s begin with Steve Stark. After all, his work left such an impact that, according to his son, Jeff, “I’ve got some friends of mine who affectionately deem Dad the 'Godfather of Cat Reman.’ ”

Now retired, Steve spent more than 35 years with Caterpillar, first joining the company in 1970. Initially, he was an operator machining 3208 cylinder heads and blocks at the facility in Davenport, Iowa. As Steve puts it, “You have to understand the history. The old Davenport plant was later to become the Bettendorf facility. Caterpillar bought that business and, when Davenport built a new facility out at Mount Joy, that building just went vacant. Then, in late 1972, the remanufacturing idea started becoming a reality.”

Back then, before the research and development hub in Mossville was in existence, Caterpillar manufactured new products — such as cylinder heads, blocks and other components for 3406 and 3208 engines — out of Davenport. Once the focus transitioned to track-type equipment, Steve moved to the facility in Bettendorf, Iowa. This happened in January 1973, right before Cat Reman released its very first remanufactured engine.

Stever explains that the building was basically empty. "We had one washer in the entire facility. The assembly line was just being put in. So, we started learning how to assemble engines. And, of course, setting up a cleaning facility, a machining area. We gradually got machines to take over those responsibilities," he says.

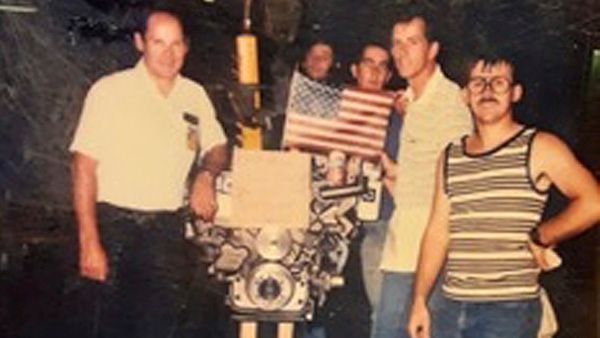

Then, in March of 1973, Steve says he and a few other employees built the first remanufactured engine, an 1160. "That was before 3208s came on the scene. At that time, we were going to start building all the 3100 series engines, the 1100 series engines and a Marine engine."

In Bettendorf, Steve started as an engine assembler but, due to the nature of the work, “everybody got their taste of a lot of different operations.” He moved to the end of the line, making fixes related to the assembly process.

By the mid-1970s, the Cat Reman production line had grown to include remanufactured turbos and the first 3406 Cat Reman engine. When 1976 rolled around, Steve supervised the disassembly area as a production foreman before moving to the third shift as a production general foreman in 1979.

THE MOVE TO CORINTH

In 1986, Steve transferred to the new Cat Reman facility in Corinth, Mississippi. He followed in the footsteps of a former Bettendorf plant manager and two supervisors who moved when Corinth opened in 1982.

Through the 1980s and into the early 1990s, Steve moved up the ladder, managing operations, then manufacturing, then an entire business unit before rounding out his career as technical resources manager.

“That’s kind of how the Salvage Development process started,” Steve says. In the early 1980s, a centralized resource handled most of the product testing, but they prioritized new parts and components. “So, I started the technical resources group in Corinth. We developed our own salvage techniques and did a lot of our own testing.”

A FRESH START FOR SALVAGE DEVELOPMENT

Through the salvage development process, Steve’s team helped establish Cat Reman’s enduring value. In one instance, “with the final drives for off-highway trucks, when we developed the laser cladding processes with the Fargo team,” this process yielded impressive results for the replacement of splines.

Like their career paths, laser cladding runs in the Stark family. Nowadays, it’s one of Jeff Stark’s primary focuses. On Corinth’s salvage development team, “we use powdered metal that can either be atomized with gas or air.” Jeff explains, “We actually feed that through an assembly that goes on our laser head. That assembly makes the powder converge at the exact focal point of the laser. The one benefit of laser cladding is it’s so focused, and it’s so much faster. Your heat input is not that of traditional welding where you might distort the part due to excess heat. So, there’s a big benefit to it.”

This process — refined over the years and applied to a variety of products — like 3600 prechambers — has helped set Cat Reman options apart from others on the market.

By relying on process improvements and being open to change, the salvage development team considers the big picture. “If I don’t have this part, now all of a sudden, I can’t build an engine. I can’t build a water pump. I can’t build an oil pump.” As Jeff tells it, this issue highlights the need for the new developments his team provides.

Alongside other procedures, Jeff’s group has handled testing around laser cladding, wire arc spray and cold metal transfer. The results of these tests help define the next generation of salvage techniques. This work impacts what Caterpillar does in Corinth and other Cat Reman facilities — like the one further south in Nuevo Laredo, Mexico.

REMANUFACTURING IN MEXICO

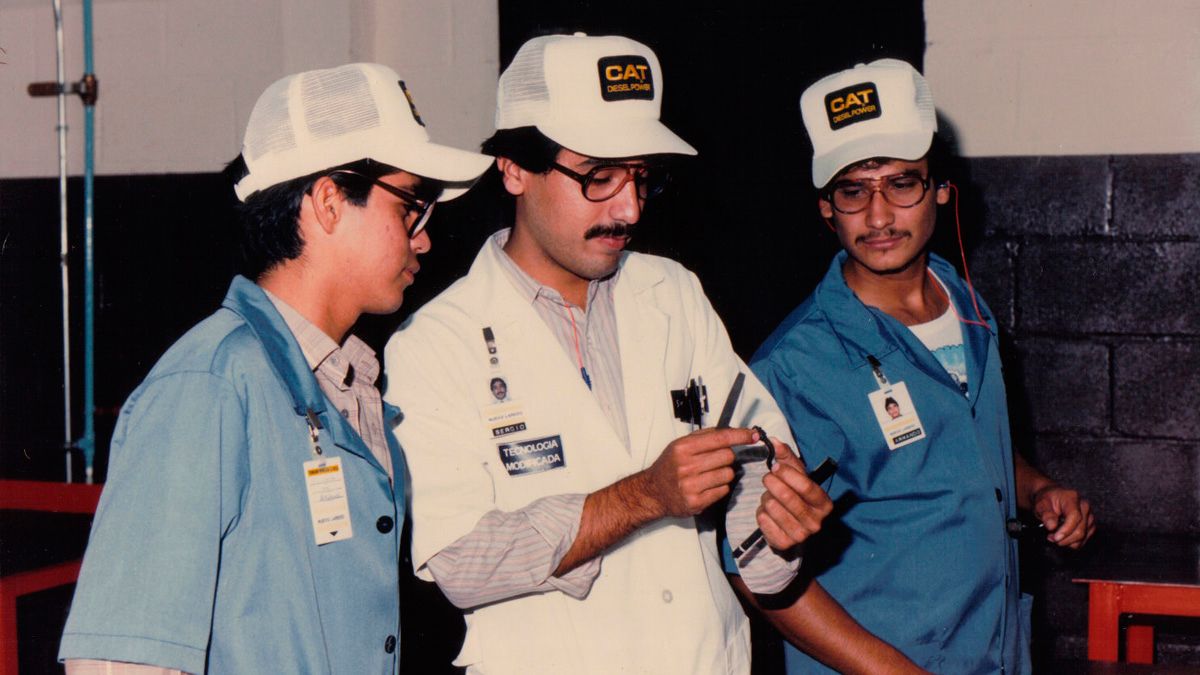

Sergio Valdez Villarreal vividly remembers his first day at work. “I started on August 16, 1988, and the Nuevo Laredo facility opened in late September or October. My first job was to supervise the carpenter who was putting the sheetrock in the offices — without having floors finished and without a cafeteria.”

Prior to joining the company, Sergio spent nearly four years as an assembly supervisor before securing a meeting with Caterpillar in Laredo, Texas — just across the border. “I interviewed with Plant Manager Roland Turner for an hour. He asked me to go to the facility on the Mexican side the next day. There, I met with the operations manager at the time, Ron Thompson. He hired me as operations supervisor right there. That was the beginning of my happy journey.”

Steve Stark remembers the early days of the Mexico facility. “Roland Turner had been the quality control manager at Bettendorf and then he came to Corinth and then he went to Nuevo Laredo. And at that point, we were mostly doing the old needle-valve injectors and some of the 3406 injectors.”

Rosalinda Vazquez Aranda, who joined the Nuevo Laredo staff in October 1999, recalls a facility that was expanding quickly. “When I started operations, we were a plant with a maximum of 300 people where we all knew each other,” she says. “At that time, specialized personnel were hired to have local support, such as engineering, and we were totally dependent on personnel in the United States. We had an accelerated growth that led us to face new challenges every week. These were stressful periods, but now that I think back, I’m sure that I would do it again.”

At its start, a decade before Rosalinda joined, Sergio was one of only two supervisors and 12 employees. Now, the Nuevo Laredo facility has a service for pick-ups and drop-offs for each shift, with nearly 1,800 employees. Despite its size, Sergio seems familiar with much of the staff, thanks to his many roles over the years. After serving as operations supervisor, he became superintendent and then manager for fuel systems operation and assembly. He moved over to quality assurance planning and then spent a year on the logistics team in Laredo, Texas, before returning to Mexico.

With his historic knowledge of the Nuevo Laredo location, Sergio makes an ideal tour guide. “In two facilities, we remanufacture fuel systems. Also, we remanufacture turbochargers. That was the second business we opened in January 2006. In the third facility, we remanufacture starters, alternators, filters, hydraulics and electronic control units (ECUs).”

In Rosalinda’s day-to-day role as general supervisor for Cat Reman turbos, pumps and injectors, she collaborates with team leaders, analyzing and evaluating ways to keep production flowing as efficiently as possible. “Every day, I work with my peers to establish and execute strategies that allow us to achieve PQVC (people, quality, velocity and cost) goals.”

At a higher level, Sergio looks for ways to improve how Nuevo Laredo does business. After overseeing the turbocharger launch in 2006, he moved on to the roles of supply chain manager, warehouse manager and technical services manager before his current position. Despite his impressive resume, Sergio remarks, “I was eating lunch with Jose. He’s been with us for a couple of months, and he asked me, ‘How long have you been here?’ I said, ‘I guess you weren’t born when I started.’ He said, ‘I’m 20.’ And I said, ‘Yeah, I’ve been here for 34 years.’ It’s been really fast. I mean, I’m just happy to be here all that time.”

As a lean Six Sigma black belt, Sergio spearheads efforts to improve Nuevo Laredo’s operation. Six Sigma is an approach to streamlining and improving processes, and in the early 1990s, Sergio ran a Six Sigma test for reducing waste and improving efficiency. Around then, Nuevo Laredo also implemented 5S, a five-step methodology for organizing a productive workspace involving sorting, straightening, shining, standardizing and sustaining.

“Now that I’m leading projects, I feel very happy working with people and working on problems that affect them with the business.” With his Six Sigma background, Sergio addresses issues similarly, “to define, measure, analyze, improve and control — so at the end of the day, it’s a process improvement.” Mainly, he develops leaner ways of tackling problems as they arise, practices that can be taught and replicated across the organization.

Specifically, Sergio and the team are working on two exciting projects. “On one project, we’re implementing an improvement on shipments from suppliers. Another is to improve the flow of materials from the warehouse,” he says. “We are looking at the whole chain because improving one link in the chain might impact another one. So, we look at involving the warehouse, receiving, traffic and customs, purchasing and accounts payable. Anyone who has a say in the chain, we’ve got them together. Even on the American side.”

“In addition,” Rosalinda says, “we’re working under ISO 9000 standards, and I have five focuses when it comes to personnel administration: sociability, communication, responsibility, inclusion and consistency.” Considering the results of their hard work, Rosalinda comments that when she started, Nuevo Laredo resembled a mechanical workshop. “We are now a business with highly qualified people and automated processes, seeking continuous improvement day by day.”

A CONNECTION THAT RUNS DEEP

While his home base is in Corinth, Jeff Stark goes down to Nuevo Laredo about once every quarter. “I can’t tell you how many people I’ve met over the years,” Jeff says. “When they’ve found out my last name, they ask me, ‘Are you related to Steve Stark?’ The first time I went to Nuevo Laredo, Sergio asked me, ‘Your last name’s Stark, right? You related to Steve Stark?’ And I just started laughing.”

As Sergio tells it, “I said, ‘I know your dad, so say hello if you talk to him.’”

Jeff continues, “Of course, he got to telling me the history of how he met Dad and trying to get everything going down in Nuevo Laredo. I think Dad even took him golfing one time.”

Simply put, the work of Jeff, Steve, Sergio, Rosalinda and other Cat Reman employees was never limited to one location. As time progressed, Cat Reman expanded to acquisitions in North Dakota, Indiana, Brazil, China and Indonesia. “In the technical resources group, we did salvage development for all those facilities,” Steve Stark says. “And Caterpillar subsidiary Progress Rail was originally purchased in the remanufacturing group — before it went out and had its own division,” which Steve’s team supported.

“That’s our job,” Jeff says, “to develop processes to be able to reuse parts. And then, once we do that, we don’t work just for Mississippi. I go to Fargo. I go to Nuevo Laredo. We actually go on-site and help them implement those processes. Right across from my desk, I’ve got a 900-pound wheel that’s come from Fargo that we’re currently looking to do some development processes for.”

BEING A PART OF CAT REMAN’S 50TH ANNIVERSARY

Fifty years of Cat Reman is quite an accomplishment. But how does it feel for the people who dedicated their careers to these products and processes? How do you sum up a lifetime of experiences?

Rosalinda considers the Cat Reman facility in Nuevo Laredo to be a second home. “I’m very grateful that it allowed me the chance to develop as a professional,” she says. “I was the second female supervisor on the floor. Now, being part of 50% of the female staff in all areas, I’m a living example that, at Caterpillar, stereotypes are broken in its efforts to be the best place to work.”

And ultimately, Rosalinda believes that the cooperative atmosphere on the Cat Reman team made it feel like her contributions have mattered. “They always cared about me as a person, not just another number on the payroll.”

That personal approach means a lot to Sergio, too. Every day, he’s motivated to make a difference with his team, and it all comes down to the people who design, inspect, remanufacture and salvage these products. “That defines Cat Reman,” he says. “The company takes care of people and, together, we put safety and quality as number one priorities. Even people from other facilities. We help each other.”

To Steve, “Cat Reman was my life. I loved it. We had a great group of people in ’73. And when I left in 2005, we still had a great group of people. Those that know Cat Reman fall in love with Reman. And a lot of them don’t want to leave. That included me.”

“You know,” Jeff adds, “my wife makes fun of me all the time. She’s a nurse, and she always tells me, ‘I wish I loved my job as much as you love yours.’ Well, I’ve got a fun job. I’ve probably got one of the best jobs in Mississippi. It’s something new every day.”

GET THE COMPLETE STORY OF CAT REMAN

Thanks for joining us on this trip down memory lane.

Discover more about our legacy at the Cat Reman Journey page, covering our decades-long backstory. While you’re there, watch our animated timeline for a colorful look at how our product line spread from a single facility in Bettendorf to a worldwide business model. And, for a higher-level view of Cat Reman history, check out this article covering how far we’ve come.