Power Need

Treating wastewater — especially for a large, rapidly growing community — is an energy-intensive and costly undertaking. Faced with the challenge to operate economically and maintain high quality, the Encina Wastewater Authority (EWA) decided energy efficiency was its best chance at success.

EWA, located in Carlsbad, California, provides approximately 350,000 customers in north San Diego County with wastewater treatment services. It established a comprehensive energy management strategy that addresses every aspect of the facility's energy use in order to create opportunity for renewable resources from biogas and waste heat.

“EWA is guided by three goals: protecting north San Diego County's ocean environment, producing and using renewable resources from the waste stream it treats, and giving rate payers a good deal,” said Chuck Bollinger, project manager for EWA.

“EWA accomplishes this through a number of initiatives, including the production of green power from biogas collected as a byproduct from the treatment of wastewater.”

Solution

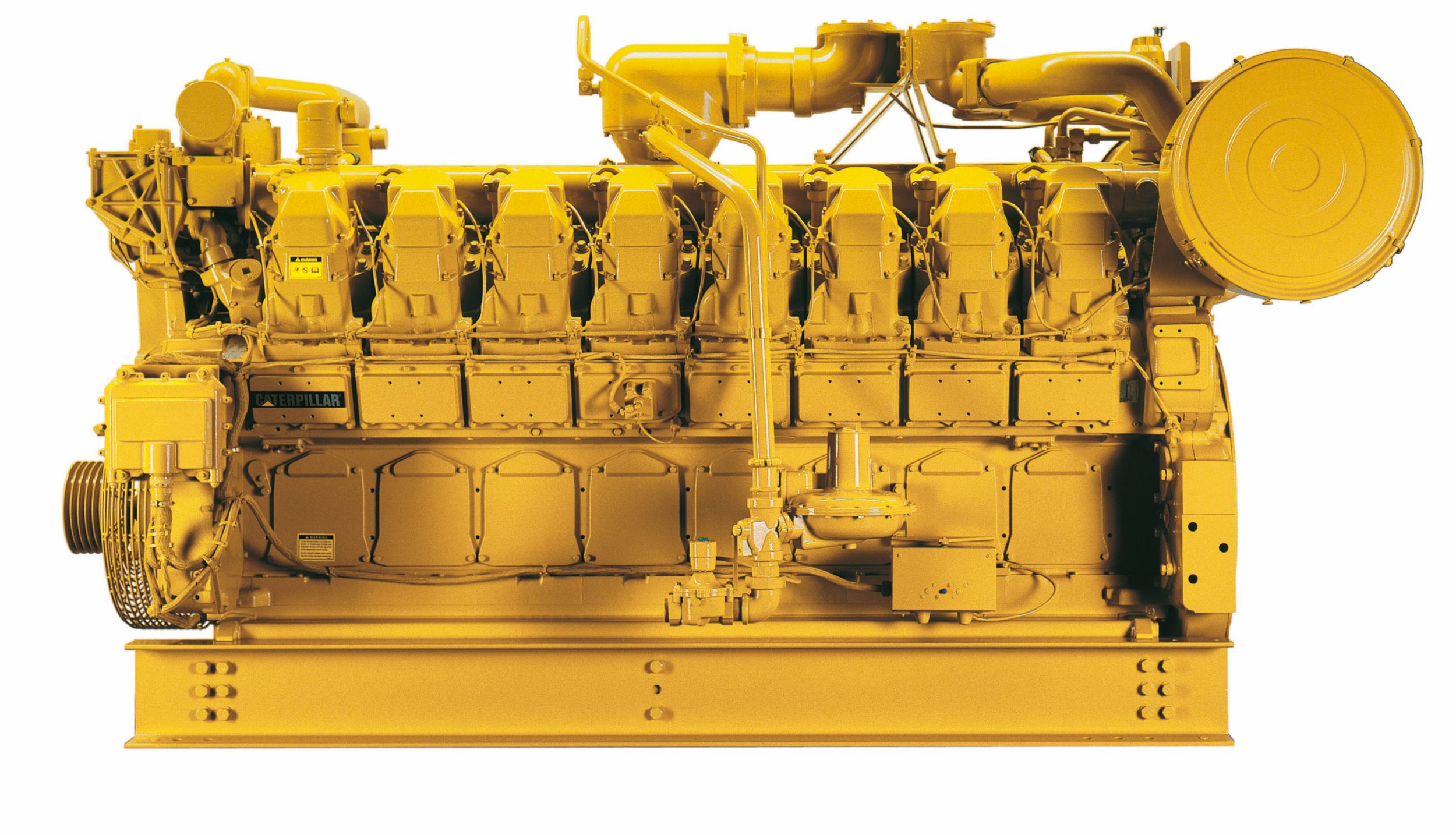

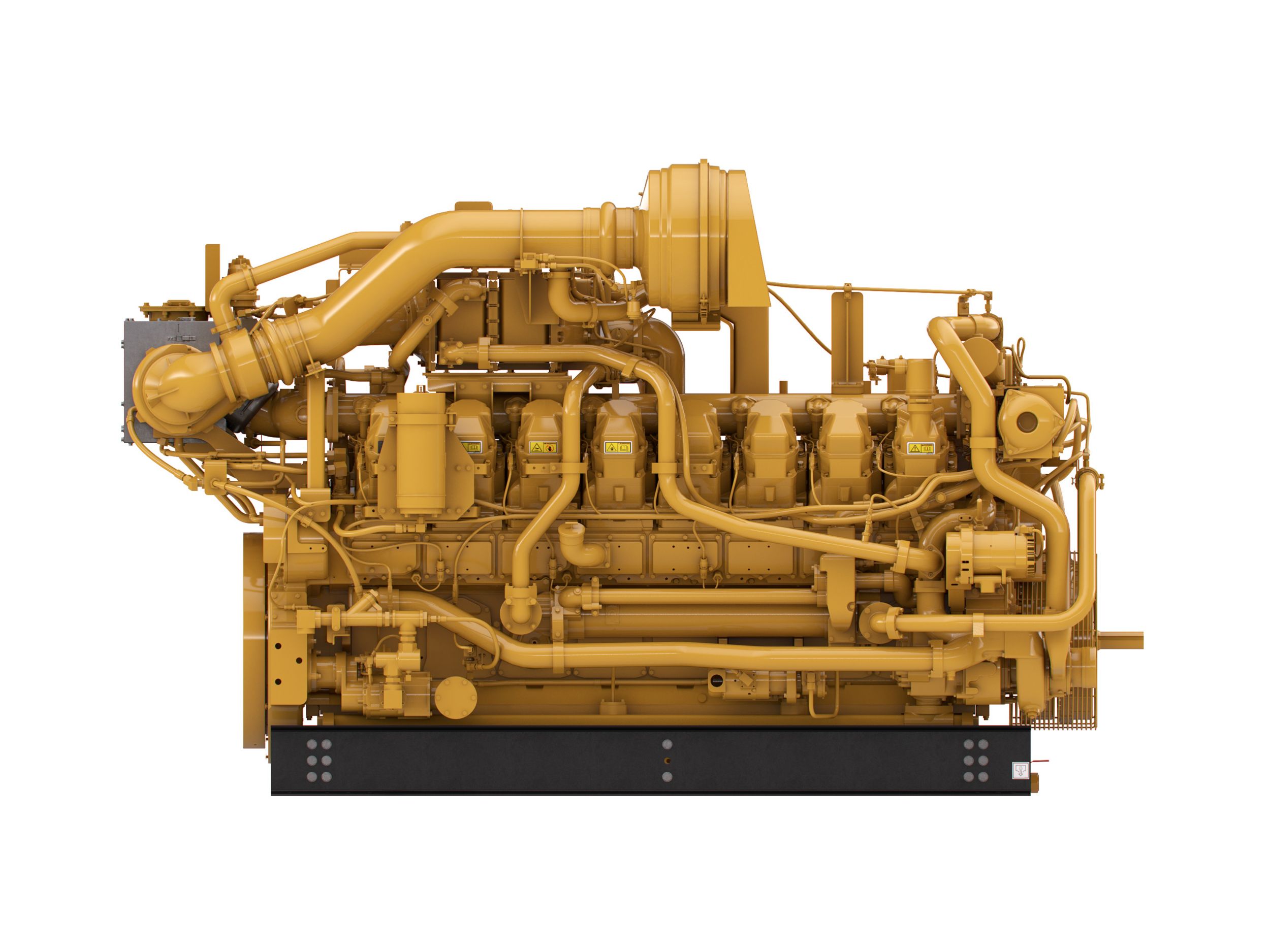

The Encina Water Pollution Control Facility (EWPCF) uses an anaerobic digester to reduce wastewater solids. The anaerobic digestion process converts volatile organic solids to carbon dioxide and methane, also known as biogas, which can be converted into reusable energy. The biogas is used to fuel four Cat® G3516 engine generator sets supplied by local Cat dealer Hawthorne Power Systems.

The generator sets can also run on natural gas. On a typical day, most of the generator sets run on biofuel and one generator set will run on natural gas alone for four to eight hours during peak rate times. Totaling about 12 million kW-hours per year, the self-generated electricity meets about 71 percent of EWA's energy needs.

EWA's energy management strategy is focused on dramatically reducing its reliance on purchased energy. The specific objective established in EWA's recently completed Energy and Emissions Strategic Plan is for the EWPCF to produce 96 percent of its energy needs onsite by 2020.

This dedication to environmentally sound energy practices was recently recognized by the U.S. Environmental Protection Agency (EPA). The EWPCF was named to the EPA's Top 20 Onsite Power Generation list, which represents organizations generating and consuming the most onsite green power within the EPA's Green Power Partnership. The Green Power Partnership is a voluntary program that supports the use of green power by offering expert advice, technical support, tools and resources.

The organizations on the list produce a combined 618 million kW-hours of green power annually — enough to power nearly 54,000 average American homes each year.

“Our mission statement is clear. We want to be an environmental leader,” Bollinger said. “But our mission is more than that. We want to provide fiscally responsible wastewater services and, by using green biogas to generate electricity, we are achieving that.” Thermal energy from the cogeneration process is used to heat the digesters, also reducing the amount of natural gas that must be purchased. As a result, operation of the cogeneration facility saved EWA $2.1 million in energy costs during 2010. Waste heat is also used in an absorption chiller to cool the main plant switchgear room.

Excess heat from the process has helped EWA save money in another way. After 15 to 20 days in the digesters, wastewater solids are pumped to the dewatering building for additional treatment. Centrifuges then are used to remove excess water. At this point, the product is about 23 percent solids and considered a Class B biosolid, which has limited commercial use. Much of what EWA produced needed to be sent to landfills for disposal.

But the biosolid pellets produced by the heat-drying process are Class A biosolids — a clean, dry, stable, granular material that can be used as a biofuel or an organic fertilizer. As a biofuel, they have a heating value that is about 60 percent that of coal. As a slow release fertilizer, they have a nitrogen-phosphorous-potassium (NPK) value of 5.7 to 7.0.

EWA produces about 7,200 tons of biosolid pellets per year. These pellets are sold as an energy source for a cement kiln in Victorville, California. EWA is also investigating using the product as a fertilizer, which would be a more lucrative market. Implementation of the heat-drying process has greatly reduced EWA's costs for biosolids disposal. In the past, four or five truckloads of biosolids were hauled to a landfill each day. Because most of the biosolids are now commercially viable Class A, only one truckload is hauled away for disposal each day. As a result, the process saves EWA — and its rate payers — another $2 million per year.

Results

EWA's Bollinger said the upgrade took years to plan and implement — the Cat generator sets were purchased in 2006 and went online in 2008 and 2009. Hawthorne Power Systems was an integral partner throughout the process.

“We chose the Cat generator sets because we liked the fact that they could easily operate on gas fuels of differing energy content,” he said. “But the reputations of Caterpillar and Hawthorne, and the fact Hawthorne has support nearby, also were important factors.”

Hawthorne provided extensive application engineering and documentation related to the generator sets, engine monitoring and control systems, and electrical power distribution and monitoring systems during the installation. EWA technicians perform routine maintenance and testing of the generator sets, but Hawthorne's certified mechanics provide ongoing assistance with major maintenance.

“Hawthorne has been a good partner,” Bollinger said.

Download the Power Profile