TECHNOLOGY VIRTUES

Each component of a hybrid microgrid brings advantages that strengthen the system as a whole.

Renewables

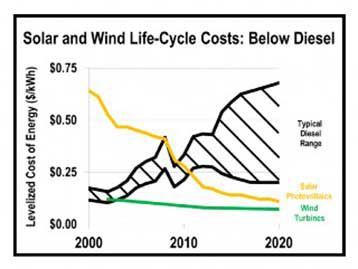

Wind and solar, while requiring higher capital and significant space, have minimal operating and maintenance costs once installed. They displace greenhouse gases and other pollutants and contribute strongly to sustainability initiatives.

Two basic types of solar photovoltaic systems can serve microgrids. The frameless thin-film technology has an energy conversion rate of about 20 percent and is well suited for hot, humid and dusty environments found in Australia, Africa and the Middle East, where its performance degrades at a lower rate than silicon panels. More costly mono crystal silicon technology is more efficient, delivering up to 25 percent energy conversion under ideal light and temperature conditions. It also requires less space than a thin-film system. However, more crystal silicon and poly crystal silicon cells degrade rapidly under hot, humid and dusty conditions rendering their performance advantage in the real world moot.

Generator sets

Reciprocating-engine generator sets deliver reliable energy and are fully dispatchable while renewable sources are offline or producing at less than rated capacity. Units in ratings from 350 kW to 15 MW and larger can be added in a modular fashion to create systems of substantial size. Multiple units add ample flexibility for variable load conditions.

Generator sets offer high power density, simple-cycle electrical efficiencies from 40 to 48 percent, high part-load efficiency and excellent capability to follow loads. They tolerate a wide range of ambient temperatures and high altitude without derating. Diesel units in particular accept load rapidly, with start times to full load as fast as 10 seconds and ramp-up time from 25 percent to 100 percent load in as little as 5 seconds. They tolerate unlimited starts and stops throughout the day with limited impact on service life or maintenance requirements. The technology is thoroughly proven and reliable, with hundreds of gigawatts of capacity installed and qualified service technicians readily available worldwide.

Generator sets also offer the potential for combined heat and power (CHP). Indeed, settings where microgrids are economically attractive – communities, resorts, industrial facilities – tend to have significant thermal requirements. Heat captured from engine exhaust or cooling circuits can be converted to steam, hot water, chilled water (by way of absorption chillers) or used in water desalination plants. In each case, the project economics can be greatly enhanced. In temperate climate zones, it is very attractive to combine CHP and solar energy because of their complementary nature. CHP capabilities are typically used during cooler times of the year when the solar contribution lessens. Energy storage helps to balance any surplus.

Energy storage

Energy storage is a key enabler of hybrid microgrids, thanks to rapidly advancing technology. The conventional energy storage system consists of banks of deep-cycle lead-acid, nickel-metal hydride batteries, flywheels or lithium-ion. However, two other energy storage technologies – ultra-capacitors and rechargeable metal-air – are now gaining favor.

Metal-air energy storage originated with hearing-aid batteries, providing long life in a safe and non-toxic package. More recently, a rechargeable capability has been developed for the zinc-air energy storage technology already common in applications such as backup power for cellular communication towers. The batteries can be 95 percent discharged and can be recharged with no cycle limit. Rechargeable zinc-air provides the most economical electricity storage, and it includes integrated controls and monitoring at the cell level.

Zinc-air batteries do not overheat or discharge dangerous concentrations of hazardous gases, and they operate in a range from freezing temperatures to 122°F (50°C) without derate. Life expectancy is at least twice as long as lead-acid batteries. The next generation of zinc-air storage will be offered in capacities at megawatt scale, well suited for the hybrid microgrid concept, and will provide an attractive total cost of ownership.

The range of energy storage technologies outlined above are used in microgrid applications today. A fully flexible offering enables a combination of these technologies, depending on the application.

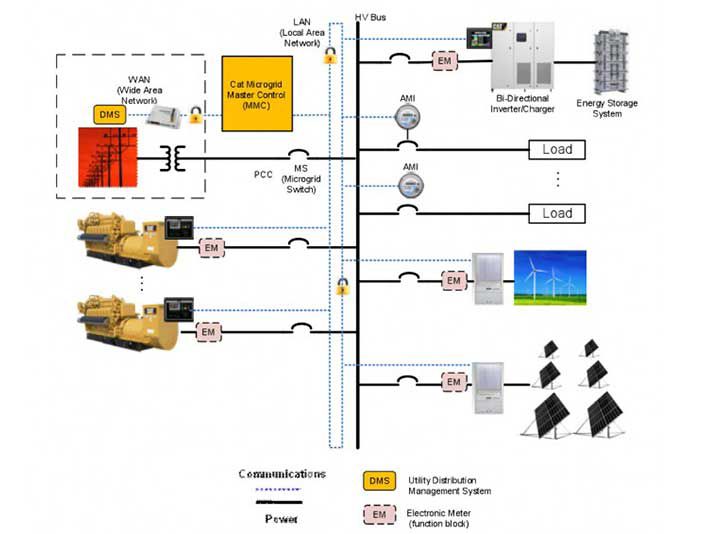

SYSTEM INTEGRATION

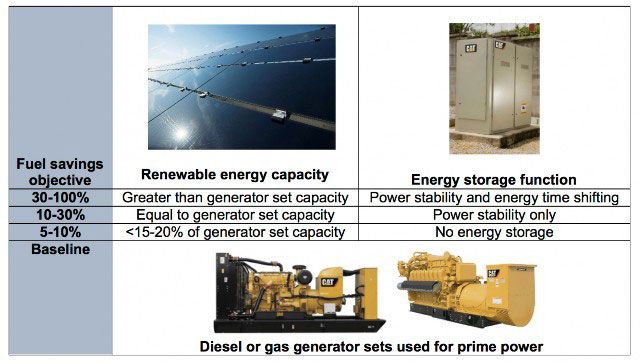

Control over a hybrid microgrid is simpler than controlling combined renewables and conventional generation in a major utility. On a utility grid with wholesale deployment of wind or solar energy, the intermittent nature of the renewables could make the grid unstable absent massive energy storage or spinning reserve.

On a microgrid, digital controls and smaller-scale energy storage enable consistent voltage and frequency with reliable kVAR control. In the event of a voltage dip, for example, the energy storage can rapidly feed energy back into the system to provide stability. Energy storage also supports the generator sets in accepting block loads without fluctuations in frequency. This capability makes it possible to deploy renewable resources in proportions far greater than a utility grid could support – up to and exceeding total system demand.

A successful hybrid microgrid deployment depends on a fully integrated system. Ideally, a single party assumes responsibility for designing the hybrid microgrid and supplying all major components – generator sets, solar photovoltaic panels or wind turbines, energy storage and controls. This party also assumes responsibility for commissioning and long-term maintenance.

Today, the major components are available as factory-built, factory-tested, containerized modules that can be shipped to the site and installed with plug-and-play simplicity. This minimizes on-site construction work and shortens lead times.

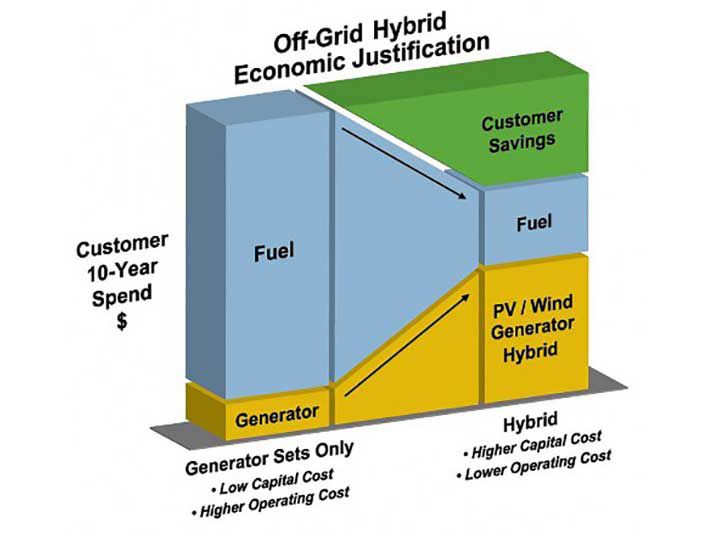

ANALYZING COSTS

The key question is determining whether a hybrid microgrid is appropriate to a given site. Analytical tools are available that make it relatively easy to check economic feasibility. An initial high-level analysis requires little more than basic information about these several factors:

- The load profile of the community or facility to be served

- The site latitude and longitude and historic solar and wind conditions

- The cost of fuel for the primary power unit generator sets

- The cost of capital

The results of this analysis will indicate whether a deeper investigation is warranted or whether the project should be abandoned. HOMER microgrid analysis software can be used to perform a much more rigorous analysis for making a final decision. This software simulates one year of system performance, uses site-specific solar and wind energy data, and predicts annual hours of operation and fuel use for generator sets. The resulting data can then be used to develop an operating protocol that enables financial optimization of the system.

CASE STUDY: TROPICAL ISLAND

A power company serving a tropical island wanted a hybrid microgrid with photovoltaic energy and a diesel-fueled generation system to help reduce its costs.

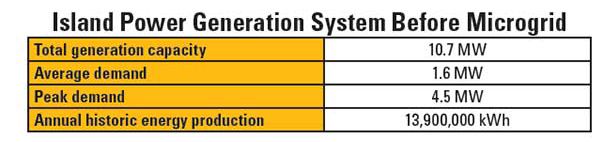

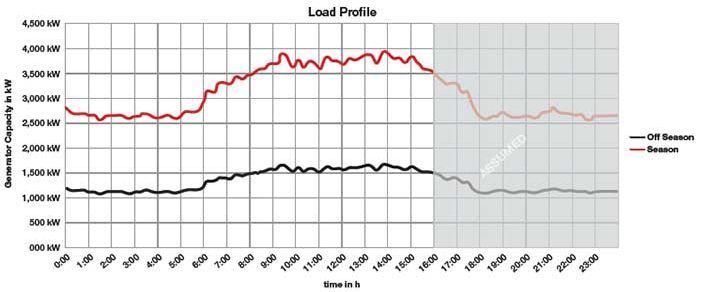

The existing power generation equipment consisted of generator sets, fueled by No. 2 diesel distillate, supplied by Caterpillar. Table 2 presents a summary of the generating system, while Figure 4 shows the daily load profile.

Evaluating renewable energy

To identify the optimal system design for the island’s needs, planners used the NASA EOSWEB database for global solar irradiation data, combined with the HOMER software tool. This enabled engineers to generate an estimate of the performance of a microgrid system incorporating renewable energy. The NASA data estimated the average annual solar irradiation to be 5.32 kWh/m2/day.

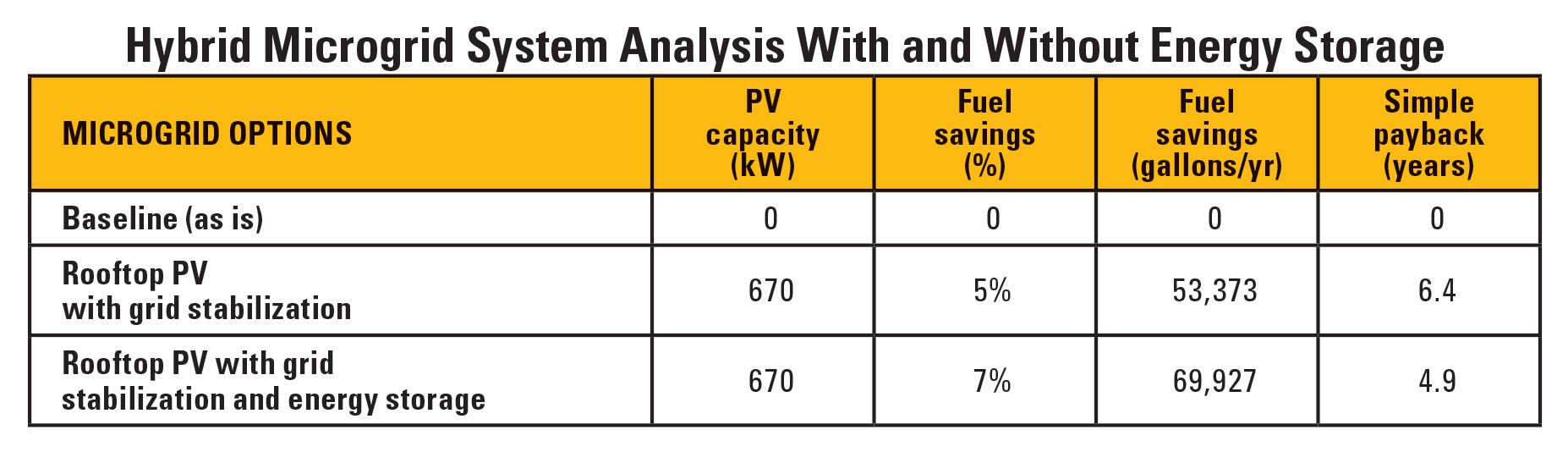

The analysis evaluated the site with a 670 kW solar photovoltaic system distributed over various rooftops. Table 3 shows the system analysis offered with and without energy storage to illustrate the financial benefits of energy storage systems.

The analysis results showed a six-year payback simply from combining photovoltaic with the diesel. The payback fell below five years with the integration of a 250 kW energy storage system, even though that system would result in a higher total capital expense.

The system demonstrates the value of the microgrid concept in combining the benefits and offsetting the limitations of both renewable and conventional power generation. The system with integrated energy storage delivers rapid economic benefits along with enhanced power system stability and availability.

The system includes rooftop-mounted photovoltaic panels, since ground space was too scarce and too valuable for that purpose. It includes 2,316 solar modules and the racking structure needed to roof-mount the panels in various locations. String inverters are also included.

The energy storage system consists of one Cat® BDP250 bidirectional energy storage inverter and two strings of batteries. The inverter interacts with the power system frequency and voltage to add power when it is needed to compensate for energy fluctuations. The grid stabilization effect of integrating energy storage helps the overall power plant maintain system frequency and voltage in a narrower control band.

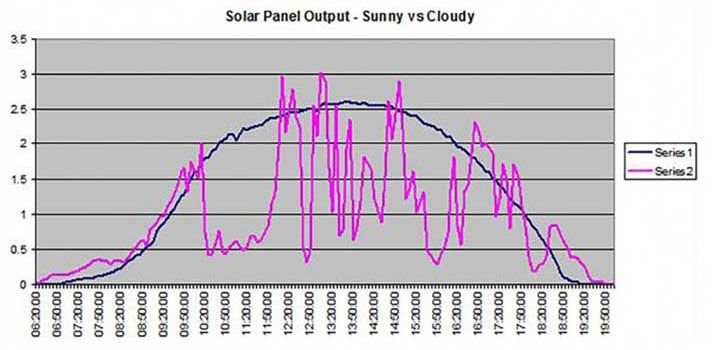

The system readily compensates for fluctuations in output from the solar panels. Figure 5 compares solar photovoltaic output for the array on a clear day and a cloudy day. During cloudy periods, solar energy generation can vary from 50 to 100 percent of the array capacity over short periods of 10 seconds or less. A sharp drop in photovoltaic output causes a sharp rise in the power required from the diesel generator sets. This causes a drop in system frequency and voltage as the diesel generators respond to the load.

The benefit of energy storage is demonstrated when the bus frequency dips. The energy storage inverter outputs power to assist the generator set in responding to the transient, thus reducing the magnitude of frequency and voltage dips. The energy storage inverter can provide 250 kW continuously, up to the storage capacity of the battery. In transient operation, the inverter has higher power capability – 150 percent for 30 seconds or 200 percent for 3 seconds. The battery capacity in this example can power the inverter for 10 minutes at 250 kW.

An additional benefit of the energy storage inverter is the overall improvement in diesel power efficiency. The energy storage system can supply operating reserve or spinning reserve for the power plant. As the power plant load rises, additional generator sets are usually started when the operating load reaches 80 to 90 percent of the running generator sets’ capacity. This provides extra capacity to respond to transient loads. Using the stored energy as operating reserve allows the system operator to wait to dispatch additional generator sets until the power system load is 95 to 100 percent of the running units’ capacity. The overall average load of the diesel generator sets is therefore higher, resulting in higher overall power plant efficiency.

The Cat microgrid control system can be used with or without energy storage in an existing power plant to control the network and integrate with all energy sources to provide coordinated control of the diesel generator sets, wind power energy sources, energy storage and photovoltaic panels. This is important because high reliance on renewable generation may cause voltage on some power feeder circuits to rise. The microgrid controls automatically adjust to maintain system voltage and power quality within specifications. The controller monitors generator set operation and maintains minimum load levels on the diesel generator sets in response to set points determined by the operator.

Where fuel consumption information is available, the microgrid controller can be used to dispatch the most efficient generator set or a combination of generator sets for a particular operating mode.

CONCLUSION

One way to simplify a project is to select a partner with deep experience in power systems, specifically hybrid microgrids. This partner should demonstrate experience in installing and integrating these systems and employ locally based service technicians who can provide support ranging from basic planned maintenance to comprehensive long-term service agreements. The ideal organization should be qualified to manage whole-project engineering, procurement and construction, while supplying all major components and ancillary equipment.

Another strong attribute is diverse financing capability with experienced, hands-on knowledge of the special needs of power projects. This can include the capability to provide financing beyond generating equipment to include the entire power infrastructure, along with offering flexible programs to suit specific needs. Project construction financing is especially helpful, providing a bridge loan while the project is being built and not yet producing cash flow. It then converts to long-term financing when the project is substantially complete.

The low and declining cost of solar photovoltaic and wind energy opens new possibilities for clean, reliable and affordable electric power in hybrid microgrid configurations. Microgrids can be quickly and cost-effectively implemented in remote locations beyond the reach of the utility grid or where the grid is unstable. These are opportune times to investigate the hybrid microgrid concept as an alternative to conventional power generation.

About the Authors

Francois-Xavier Saury is Microgrid Business Development Manager for Europe, Africa, the Middle East and the Commonwealth of Independent States with Caterpillar Inc. and is based in Geneva, Switzerland.

Craig Tomlinson is Product Support Readiness Manager with the Microgrid Team in the Electric Power Division Of Caterpillar Inc. and is based on Houston, Texas.