Cat® helps power Poleset Equipment to new heights.

Poleset Equipment, a utility equipment manufacturing company based out of Western Pennsylvania, offers machines that make line work easier and safer. Setting poles for electric and utility lines in a mountainous region can be dangerous and difficult due to terrain and weather conditions, and the team has been tackling these difficult tasks since 1991. When the Poleset team became dissatisfied with the equipment on the market, they decided to make their own machines. Designed for the electrical utility distribution and sub-transmission sector, these machines provide accessibility and a safer way to work.

Poleset began designing machines in 2004: the Xtreme Polesetter II 47-ft Digger that drills pole holes and sets class 2 poles up to 80’ in height, and the 60-ft bucket that has the capability to angle around multiple powerlines to make line work safer. Both machines have the dielectric capability to work on energized power lines, eliminating the need to shut power off for repairs. Because of the considerable size of the machines and the scope of line work, most of their business is rental.

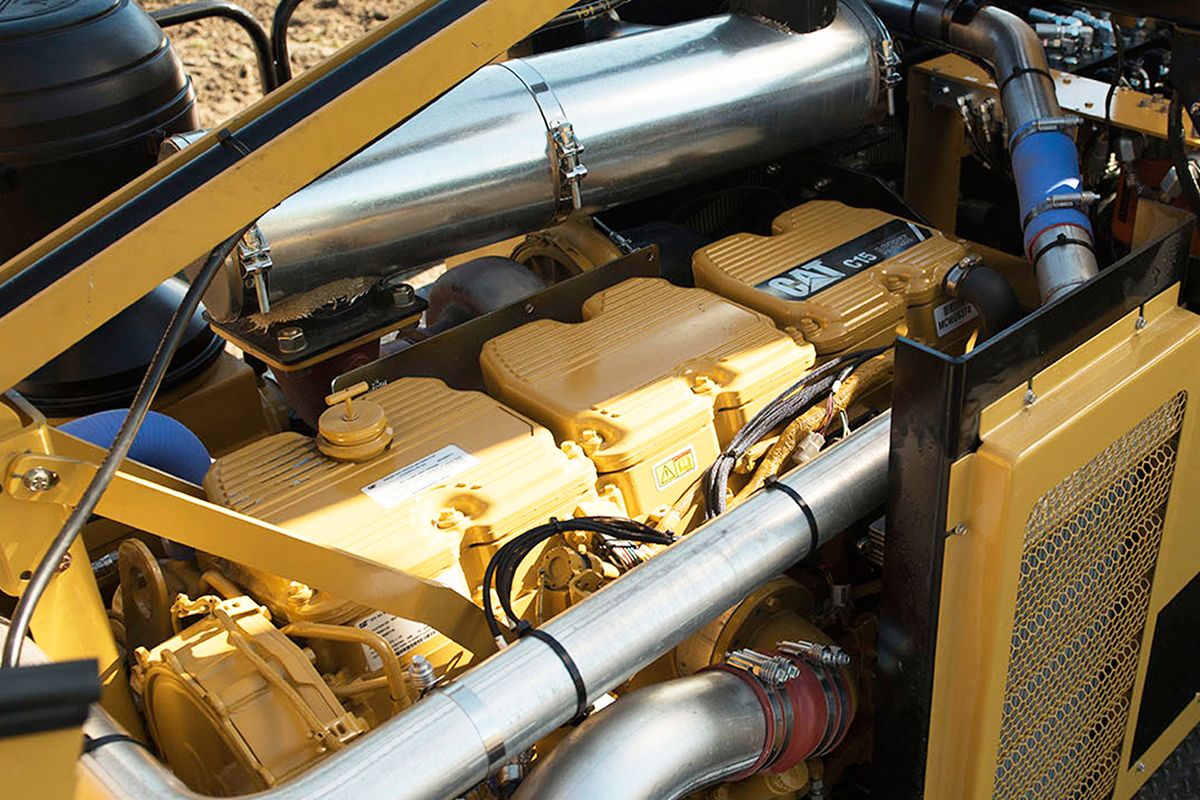

By 2006, Poleset updated their machines and switched to Cat® engines. The new configurations for both the Xtreme Polesetter II Digger and Bucket allowed the Cat C4.4 industrial power unit engine to be dropped directly into the machines, reducing time spent on installation and maintenance. Poleset can now rely on the durability and power of Cat engines, along with the unparalleled network of parts and service offered by Caterpillar.

Designed and built by people who know the work.

The company’s founder, Bruce Livingood, worked in the power line industry and faced the many obstacles involved with the job. Because of his firsthand experience, the equipment is designed with the unique needs of operators in mind. The company’s mission is to protect line workers and extend their careers.

For example, the Xtreme Digger II and Bucket II are both run by remote control. This allows companies to keep their operators at a safe working distance. Remote capabilities also keep their crew numbers down with fewer people needed to operate a machine.

“The person working the remote can walk around and see where they need to be—where to place the materials and drill the hole. Everyone is more aware of what’s going on.” – Bruce Livingood, Owner of Poleset Equipment

Through the years, modifications have been made to the Xtreme Polesetter fleet to improve functionality. The equipment can travel through heavy snow, ice and high winds. These modifications drastically improve efficiency and are made possible because Poleset professionals walked the walk. They used their machines in the field and realized what changes needed to be made.

The Xtreme Polesetter II Digger comes equipped with a 47-ft boom and a pin-on bucket that is engineered specifically to work electric lines. The Xtreme Polesetter II Digger is easy to transport, due to its compact frame, and is custom-equipped with a full capacity digger or outfitted with an insulated bucket, as needed.

The Xtreme Polesetter II is equipped with a 2000-lb. jib and can be used to set transformers. Because the Xtreme Bucket II has an articulating arm, it can be maneuvered around multiple power lines and make connections to the electrical apparatus easily.

A massive machine requires a lot of power.

Power line materials are heavy. Poles can be as high as 80 feet, weighing as much as 3,000 pounds. You have to have equipment that can handle these supplies. Both the Digger and Bucket weigh close to 30,000 pounds to ensure they have the ballast for the booms to handle lifting weights without tipping over. The machines can also pull skids and trailers full of heavy materials to and from jobsites. This saves utilities time and money, but all that force requires an exceptional engine.

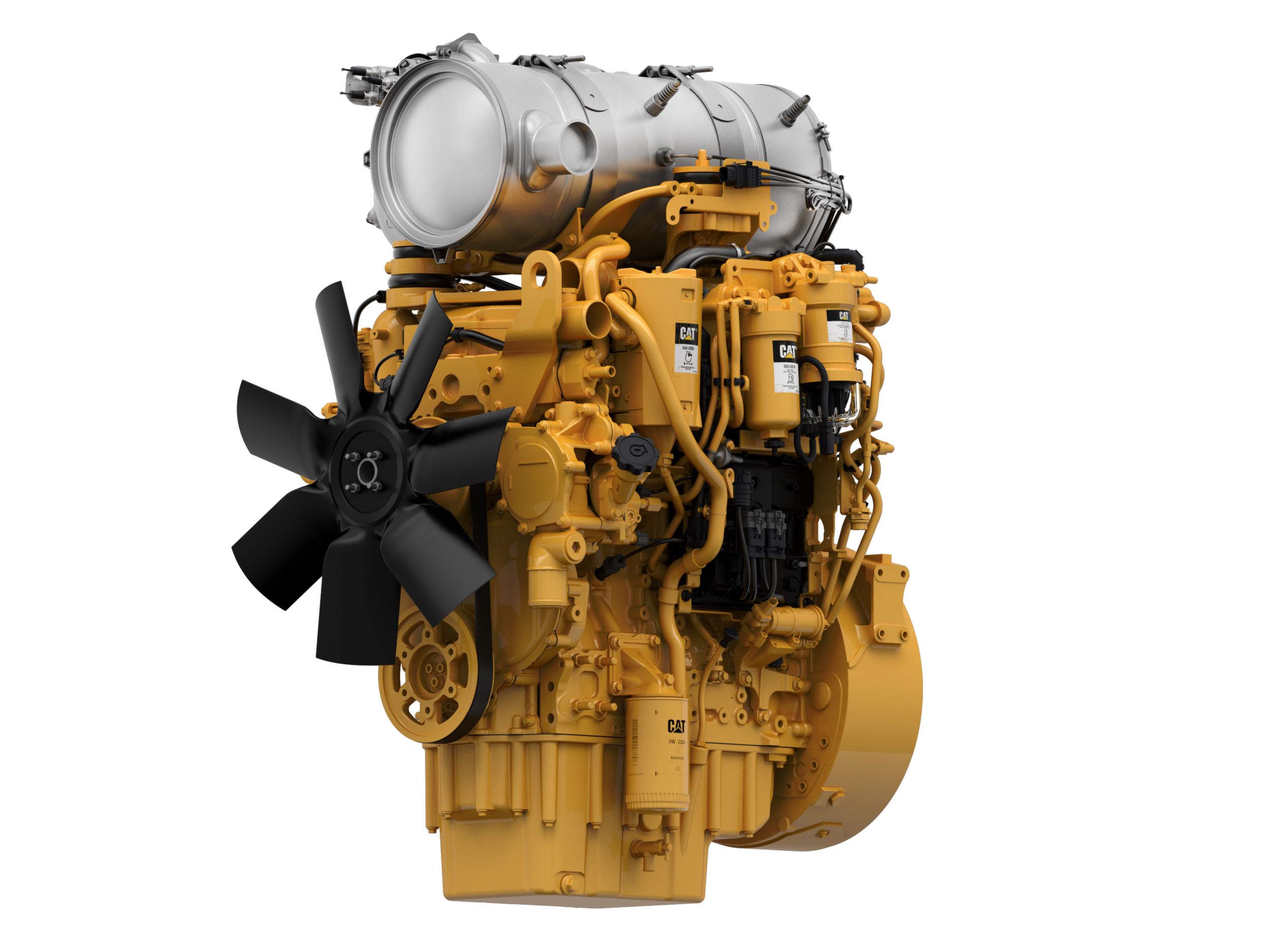

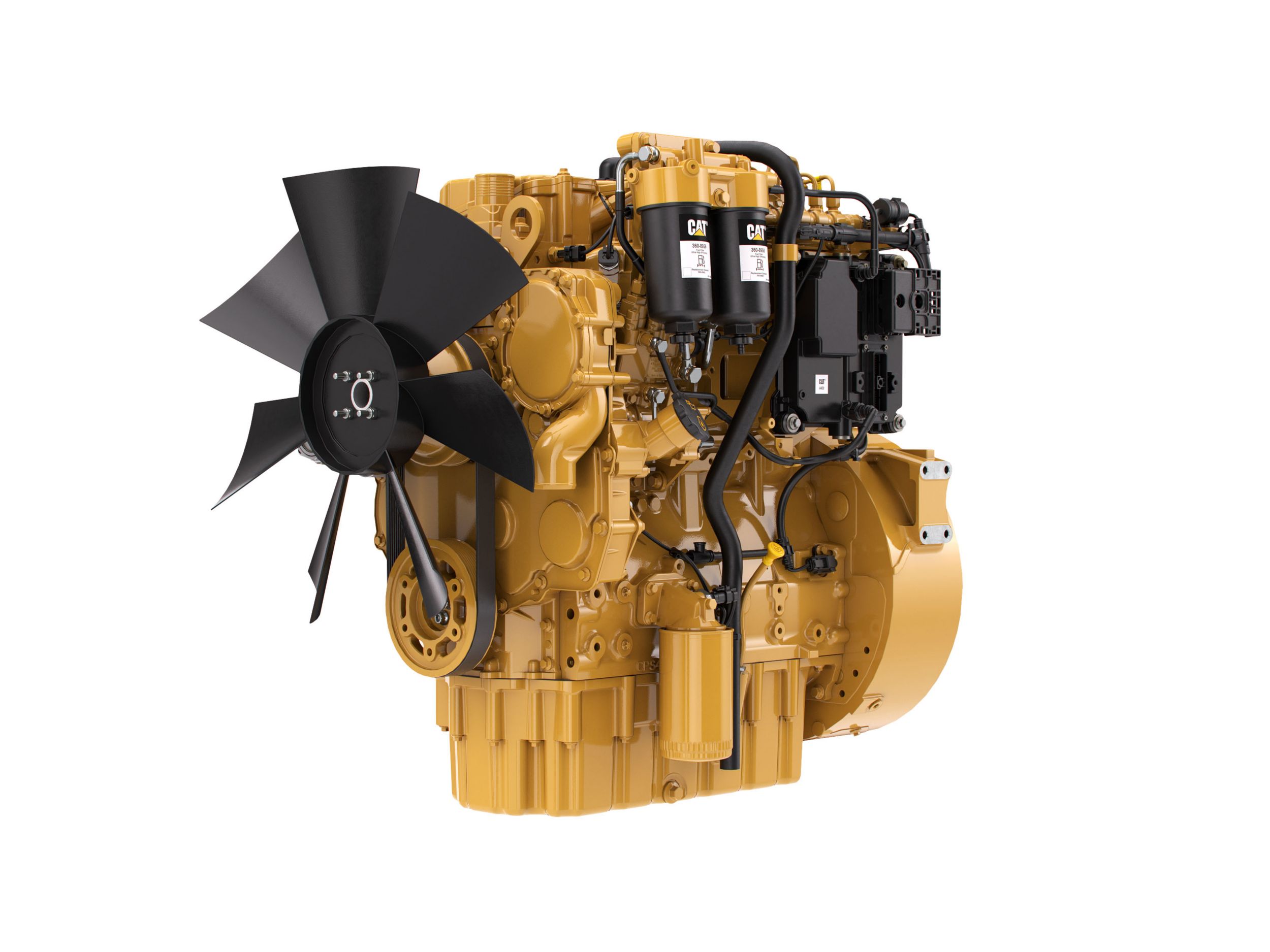

Poleset chose the Cat C4.4 industrial power unit (IPU) engine to handle the power requirements of both the Xtreme Bucket II and the Xtreme Polesetter II Digger. The engine is rated from 82-150 bkW (109-200 bhp) @ 2200 rpm.

“Sometimes when you get called out on storm trouble, it’s minus-five degrees and you need that engine to start up. The Cat C4.4 engines are small enough where we can put two batteries in them and they will start up whenever we need them.” – Max Livingood, Co-Owner of Poleset Equipment

Poleset worked directly with their Cat dealer, Cleveland Brothers, when developing their equipment to streamline engine integration. They tested the Cat C4.4 engine for heat range and power capability to make sure it was the right fit. It’s been close to 20 years, and they’ve stuck with the Cat C4.4.

“When you’re working in storm conditions, you might be away from your home or office for a month. You just can’t have equipment breaking down. A lot of people are depending on you to get the power back on.” – Bruce Livingood, Owner of Poleset Equipment

To ensure Poleset Equipment is more sustainable and compliant with emissions standards moving forward, they are upgrading to Stage V Cat engines in their machines. The upgrade to Stage V engines reduces emissions and allows Poleset to operate machinery in areas with stricter exhaust emission standards, such as Utah and California. Poleset has standardized to one single engine, the Cat C4.4, across all machines to improve efficiencies.

“Reliability, serviceability, the parts . . . we really need the type of support Caterpillar provides with their engines.” – Matt Dove, Vice President of Sales and Marketing, Poleset Equipment

Cat delivers long-term value.

It’s not just Cat engines that Poleset Equipment relies on. Competitors of Poleset use flex tracks or rubber tracks for their tracked utility equipment. Poleset uses Cat steel tracks for Xtreme Polesetter II machines because they have proven to be more reliable in extreme conditions.

“It’s been a huge competitive advantage for us to be able to ask potential clients: ‘How much does downtime and maintenance cost your company? What are your engine maintenance costs each year?’ It allows us to highlight the reliability of our track machines and potential cost savings, regardless of whether they own or rent track equipment,” says Dove.

Specialized machines for important work.

The Cat dealer network is spread across the map, meaning Poleset customers are never far away from help, when needed. Poleset runs its own operation, and it helps not to have to send their own techs out when repairs are needed. Rented machines usually take a beating, but Cat IPU engines are reliable and durable to handle the workload.

Power lines are vital for communities across the map. Whether a utility needs new lines installed or a storm wipes out a grid, people count on Poleset Equipment and Cat engines to work. Together, Cleveland Brothers Cat and Poleset are providing a valuable service.