If you already have an existing account with another Cat App, you can use the same account to sign in here.

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

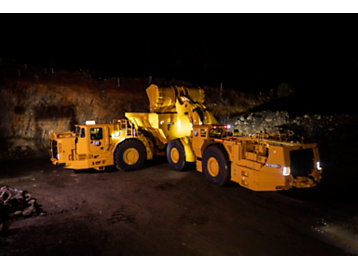

R2900 XE UNDERGROUND LOADER

The R2900 XE was built from the ground up for increased production. Its 18.5-tonne (20.4-ton) payload allows it to load Cat® AD63 trucks in 3 to 4 passes for maximum throughput.

Faster acceleration, instant machine response and higher speed on grade make for shorter cycle times, while greater breakout force and higher lifting height make digging and loading faster than ever.

REDUCED MAINTENANCE AND REPAIR

A number of features and improvements make the R2900 XE easier and less expensive to maintain, driving down cost per ton and keeping your machine hard at work instead of sitting in the shop.

- More durable powertrain requires less maintenance

- Stronger frame increases durability and extends life

- Traction control reduces tire spin, decreasing replacement times and costs

- Longer component lives and extended service intervals boost availability

The R2900 XE delivers a 20% increase in productivity thanks to a number of new and improved features. Smooth and quick machine responses are combined with improved digging and tramming performance. In addition, employing electric drive components reduces fuel burn and improves productivity.

CAT GROUND ENGAGING TOOLS (GET)

BOLT-ON HALF ARROW

Cat bolt-on half arrow (BOHA) GET can reduce changeout times while extending the life of traditional weld-on GET options — allowing the R2900 XE to perform even better in heavy, hard-digging rock conditions. BOHA GET are bolted onto the bucket instead of welded, shortening replacement time from as much as 40 hours to as little as one or two. And with no need for welding, they are easier to replace.

DURILOCK™

- Standard: wedge shape for general production and development

- Abrasion: contoured to put more material on the shroud base

- Penetration: less leading-edge material to easily penetrate dense material