With roots in the region dating back to its origin company’s first commercial natural gas well in 1878, EQT has grown to become the largest natural gas producer in the U.S. today, with 25.0 Tcfe of proved natural gas, natural gas liquids (NGLs), and crude oil reserves across approximately 2.0 million gross acres. EQT has a long-standing commitment to environmental, social, and governance ESG initiatives and is committed to responsibly developing its world-class assets. The company is on track to meet its previously announced targets to achieve net zero Scope 1 and 2 greenhouse gas (GHG) emissions in its production segment operations by or before 2025. For example, EQT recently announced the completion of a $28 million company-wide initiative to eliminate 100% of its natural gas-powered pneumatic devices from its production operations. As a result of this initiative, EQT has reduced its methane emissions by 70% and its annual carbon footprint by 305,614 metric tons of CO2e2 .

PROMISING PERFORMANCE OF HYDROGEN FUEL

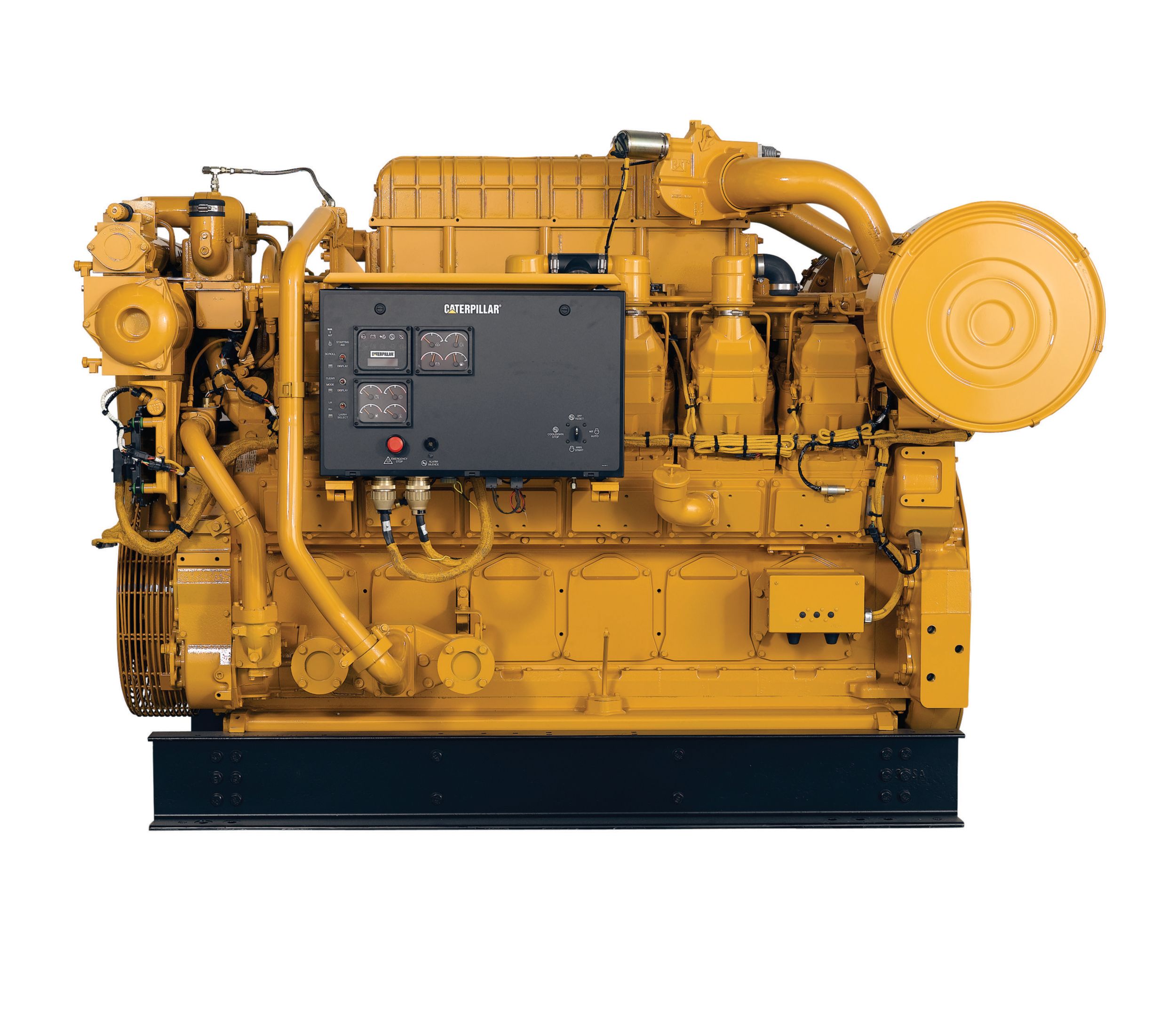

As part of these ongoing environmentally responsible initiatives, EQT sought to evaluate the performance of a land drilling power module fueled by varying blends of diesel, compressed natural gas (CNG) and hydrogen. Company engineers selected Caterpillar and Cleveland Brothers, the local Cat® dealer, to design and manage a bench test and three-week field demonstration of a 1 MW Cat 3512C land drilling module equipped with dynamic gas blending (DGB™) technology.

“For decades, we have relied on the reliability, durability and consistency of Cat power solutions throughout our production sites, which is why we selected Caterpillar and Cleveland Brothers to spearhead our initial hydrogen demonstration project on our journey toward a reduced carbon future,” said Jared Lowery -sr drilling team lead at EQT Corporation. Collaborating with Cleveland Brothers, Caterpillar performance engineers initially performed a 22-hour yard test at the dealer location in Hunker, Penn., to measure the response of the engine and various diesel and gas blends supplied by Certarus. These included 100% diesel, 30% diesel and 70% CNG, and 30% diesel with blends of hydrogen into CNG. The demonstration included a series of steady state test points and transient operational test points, including load steps, load sheds and gas shutoffs.

After the yard test confirmed the performance of the engine with the diesel/gas blends, EQT moved forward to a more rigorous field evaluation of the power module at its natural-gas production well in Waynesburg, Penn. Again, the performance of the engine and power module operating on multiple blends of diesel, CNG and hydrogen fuels was measured across a series of steady-state and transient operational test points.

After more than 350 hours of testing, engineers concluded that the power module operating on fuel blends including hydrogen experienced no negative impact on performance in a production environment, with no difference in transient response using the highest hydrogen blend. Additionally, the addition of hydrogen to the fuel mix resulted in a minimal impact on combustion and negligible change in engine efficiency, while peak cylinder pressure remained constant.

Engineers identified areas for future development, including the evaluation of the long-term effects of hydrogen combustion on engine components, acceptable hydrogen limits for broader deployment, hardware and software customization, and the identification of applicable regulatory certifications, and hydrogen fuel delivery and storage considerations.

“As an operator of choice focused on delivering long-term value for all our stakeholders, we have embraced our role as a catalyst for transforming technology, culture and environmental performance, and this demonstration project was an important step forward in understanding the viability of hydrogen as a fuel in a production environment,” Lowery added.

LEADING-EDGE SUPPORT FOR ALTERNATIVE FUELS IN POWER SYSTEMS

The demonstration project is the latest in a series of initiatives across the Caterpillar enterprise to develop and commercialize hydrogen-fueled power solutions. “Caterpillar is serving as a trailblazer in the use of hydrogen and other lower carbon fuels for power solutions across numerous markets and applications,” said Matt O’Sullivan - general manager Caterpillar Oil & Gas. “Our collaboration with EQT and Cleveland Brothers shows how we can support our customers in the energy markets by reducing their environmental impacts and helping them lead their industries in the energy transition.”