If you already have an existing account with another Cat App, you can use the same account to sign in here.

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

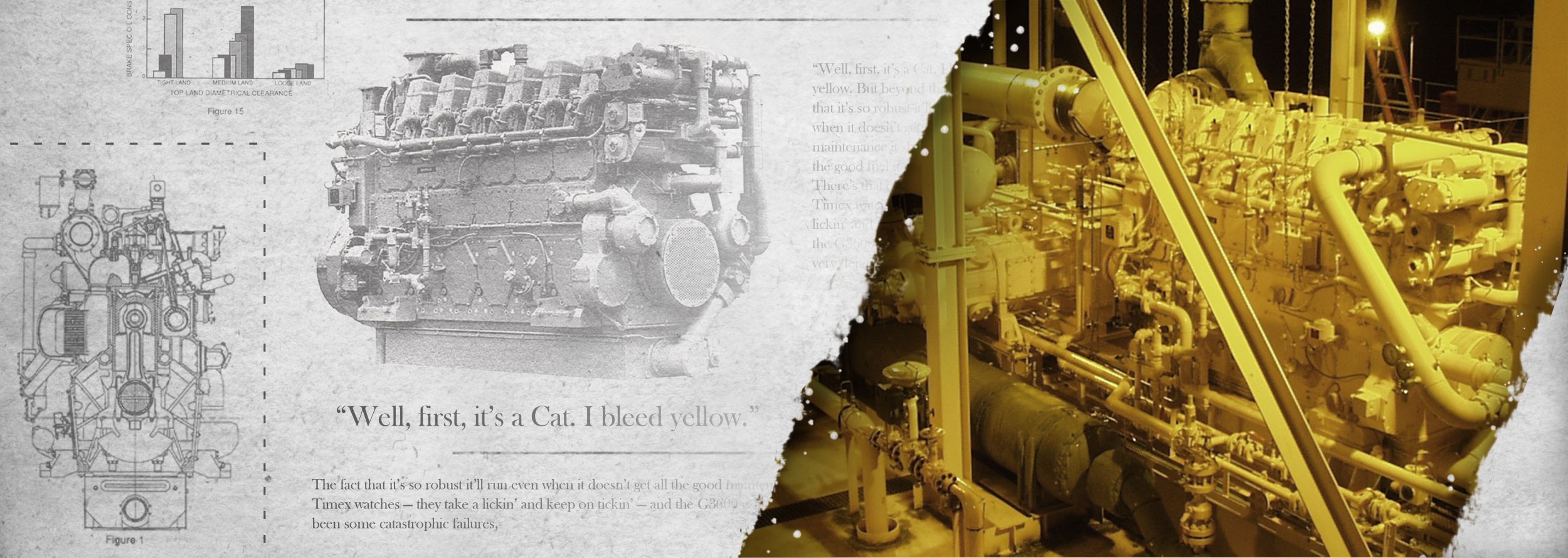

A MAN AND AN ENGINE CELEBRATE 30 YEARS IN GAS COMPRESSION

Most everyone in gas compression knows the Cat® G3600 engine platform, which is celebrating its 30th anniversary in 2021 — but not everyone has experienced it from both the customer side and the Caterpillar side. That makes Bobby Runnels’ perspective unique.

Bobby got his start in the industry in 1994 working for the company now known as Exterran, where he serviced G3600s and trained others to operate and maintain them. In 2009, he joined the Caterpillar Oil & Gas team and now serves as gas engine product support engineer and a Caterpillar Certified Training Instructor. We asked him to step back in his time machine to the launch of the G3600 in 1991.

Caterpillar Oil & Gas: Do you remember your first impressions of the G3600?

Bobby: I’d primarily worked on G3500 and smaller products before then, so it was much bigger than the typical Cat products I was accustomed to. The horsepower capability was pretty phenomenal — it didn’t have any competitors in its speed. There were other manufacturers who had similar product out there, but from a lean burn perspective, the G3600 had very few competitors. The emissions on the engine were cutting-edge quality at the time. Emissions reductions were a focus even back in the 1990s.

Caterpillar Oil & Gas: What was the biggest improvement you saw in the G3600 over time?

Bobby: The development of the A3 controls strategy was one of the biggest steps forward. The original controls system was called ESS, and it was really cumbersome. Electronic controls were still really new on gas engines then, and at that point the G3600 was the most technical engine on the market from a controls standpoint. It required a greater level of understanding to be a technician on this engine. When Caterpillar introduced the A3, that completely changed what the tech’s capability needed to be — it simplified things and made the engine much easier to work on. Runtime and reliability improved.

“WITH THE A4 CONTROL SYSTEM, CLEANER EMISSIONS RATINGS AND A WIDER RANGE OF FUEL CAPABILITY, THE G3600 IS FAR SUPERIOR TO ANYTHING ELSE ON THE MARKET TODAY.”

Caterpillar Oil & Gas: You were working at Caterpillar when the successor to the A3, the A4, was introduced. What can you tell us about what drove that change?

Bobby: Emissions and fuel flexibility. We weren’t losing sales on the A3, but we were looking to go even lower on emissions and have an even more up-to-date controller. Technology moves on and controllers become outdated. It’s just like your laptop — that old IBM ThinkPad you used to use is long gone. With the A4 control system, cleaner emissions ratings and a wider range of fuel capability, the G3600 is far superior to anything else on the market today.

Caterpillar Oil & Gas: What was your most interesting G3600 experience back in your days as a technician?

Bobby: We had a customer in the Gulf of Mexico working in a competitive zone. They had two G3608s driving gas compressors. Anytime those engines went down, they projected that they lost $1 million an hour. If they couldn’t get them back online within 20 minutes, they would call Exterran, ask where I was and send a chopper to come and get me. Typically, I could diagnose most things once I got on site and have them back online in an hour if we had the parts. This was back in the early days of the G3600 when it still had the ESS controls system.

Caterpillar Oil & Gas: You’ve seen big changes in technology and connectivity since the G3600 was introduced in the early 1990s. Do you think that will ever replace the need for a technician on site?

Bobby: I always see there being a need for a more advanced technician who can read the 0s and 1s and understand what they’re telling him. Some of that is becoming automated through tools like Remote Fleet Vision and other technologies that can diagnose what’s going on with an engine, but you still have to rely on the skill set that the human being brings to the game.

Caterpillar Oil & Gas: What do you think has been your biggest influence on the development of the G3600 over the years?

Bobby: Probably teaching others about it. In my later years at Exterran, I was a training instructor showing technicians how to work on the engine. Coming from there to Caterpillar, I still try to keep teaching people the correct way to do things, although not formally. I get a lot of calls from technicians — many I’ve known for a number of years.

Our thanks to Bobby for sharing his G3600 memories — and for continuing to share his expertise with others in the field today.

Related Articles

-

Q&A with G3600 Sweepstakes Winner Caleb Upchurch

Meet the April winner of our G3600 30th Anniversary Sweepstakes and find out about his experiences with “Wally” and other Cat® G3600 gas engines.

Learn More -

The Best Engines In Gas Compression

Al Hunt stopped counting after visiting 100+ sites to commission G3600 engines. Walk down memory lane as this retired dealer employee celebrates 30 years of the G3600.

Learn More -

Early Days of the G3600

Just two years after its launch, the new Cat® G3600 engine platform was already making its mark. Check out the highlights from this internal status report.

Learn More -

30 Years of Milestones

Take a look at some of the key milestones in technology, entertainment and business that have taken place since the launch of the Cat® G3600 platform in 1991.

Learn More -

30 Years By The Numbers

Take a look at this infographic to see what 30 years of performance looks like for Cat® G3600 gas compression engines.

Learn More