Houston, Texas - For decades, Caterpillar Oil & Gas has powered the gas compression industry with industry-leading gas-fuelled engines, including the legendary Cat® G3500 and G3600 product platforms. Built using the proven Cat diesel designs, Cat gas-fuelled engines have stood up to the most demanding natural gas applications for more than fifty years, delivering legendary reliability and durability. The Cat G3600 engine family alone has logged over 140 million hours of operating hours around the world.

Cat new product introductions for the industry have been strategically designed to broaden the product portfolio where customers have requested additional capability from the reliable Cat horsepower. As customer needs have become more complex, the Cat solutions have been specifically engineered to address needs across the upstream, midstream and downstream operations, including increased fuel flexibility, efficiency and higher power density.

In recent years, Caterpillar has invested heavily in its gas compression engine line-up with the launch of the G3500B, CG137 and G3300B series engines. These product updates have increased each engine’s performance in areas critical to delivering value to customers. Power increases, electronic controls, and emission performance have all been enhanced through these efforts. Additionally, to help customers manage their Cat fleet more efficiently and maximize operations, Product Link™, the flagship telematics solution from Caterpillar, is now standard for the G3500B and G3600 engines.

Further product enhancements are continuing. In March 2015, Caterpillar released the latest version of its G3600 engine. The G3600 A4 provides users with an increase of over 5.5% in horsepower rating and allows for operation over the broad range of fuels found in today’s compression applications. Further horsepower increases are possible when operators take advantage of the engine’s ambient temperature capability that allows more horsepower to be available from the G3600 A4 seasonally or daily when local temperatures are below summer highs. The G3600 A4 delivers reliable in-cylinder NOx emissions control at 0.5g/BHP-Hr. Additional emission capability is planned to be released later this year, when a 0.3g/BHP-HR NOx rating will become available. The 40% NOx emissions reduction will be accomplished with only an engine software update, allowing a significant reduction in emissions from the factory or later in the field when needed.

Future product updates will include a G3516 TA engine capable of meeting 0.15g/BHP-Hr with a customer provided three way catalyst. The new engine will be rated at 1,380 hp, the same as today’s G3516B. First production deliveries of the G3516 TA will be in late 2015.

While the rugged Cat engines have been racking up operating hours at global gas compression sites, the gas compression industry has evolved with more stringent local emissions regulations impacting operations. Dave Dunlevy, Caterpillar Oil & Gas general manager noted, “We’ve seen a trend towards the utilization of electric motors and drives in gas compression applications as shale gas proximity to areas serviced by utility power has grown.

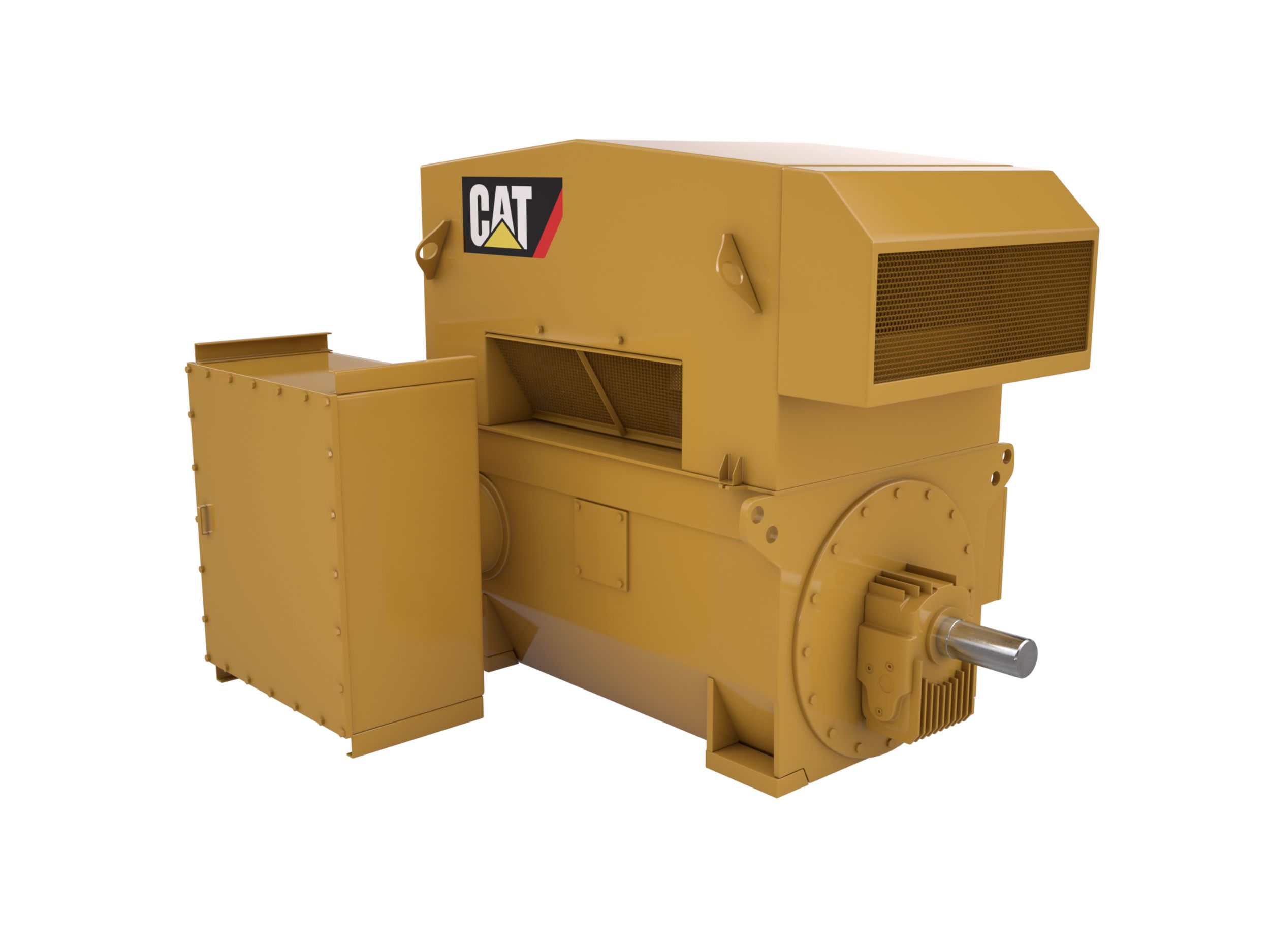

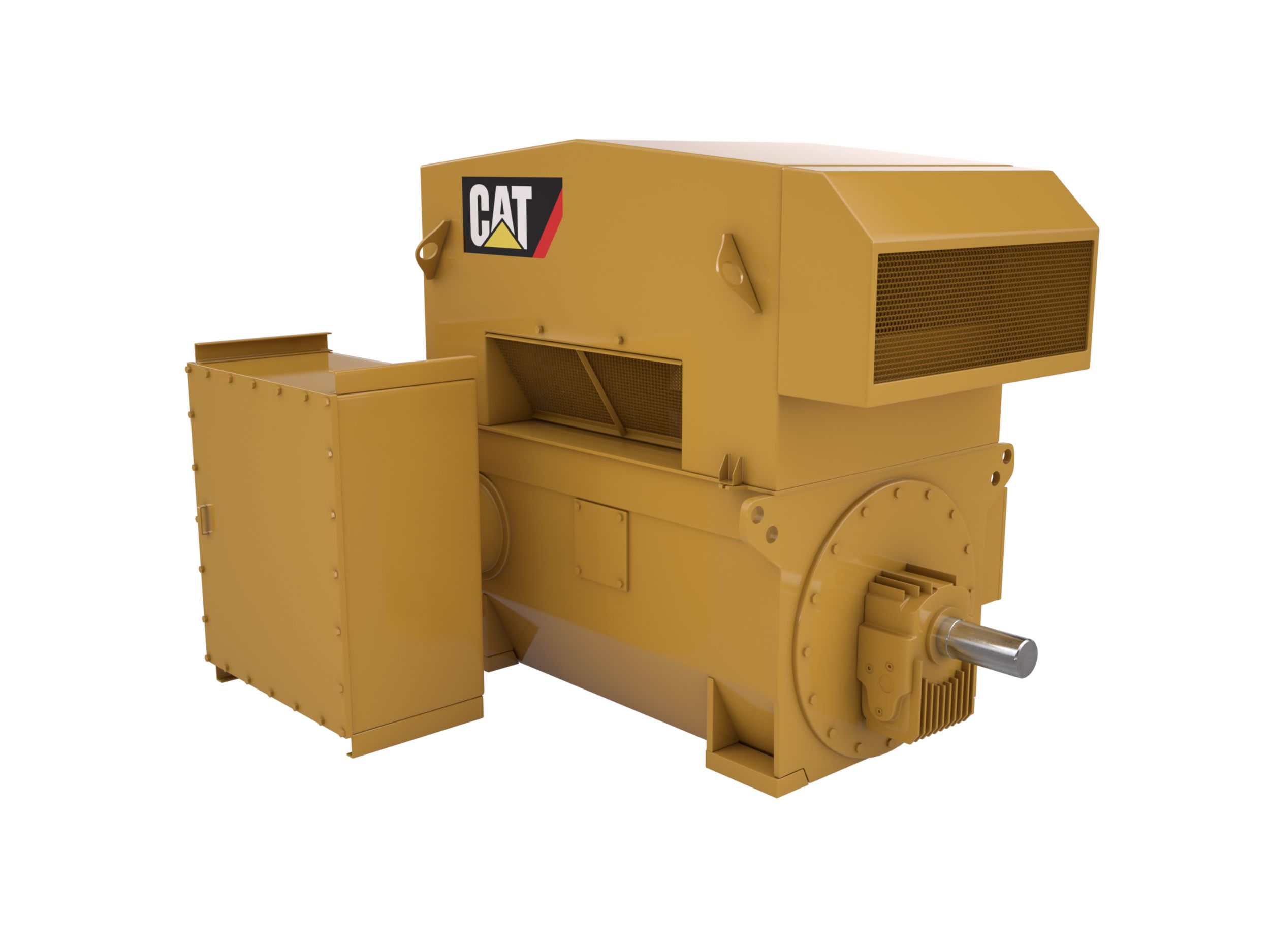

To help customers achieve success in varied operations, Caterpillar Oil & Gas is launching Cat® electric motors and variable frequency drives for the gas compression. The new electric motors and drives will complement Caterpillar’s existing product portfolio of gas compression reciprocating engines designed for the gas compression industry. The motors will be purpose-built for gas compression applications and be available as standard products in power ratings ranging from 1,500 – 5,000 hp with paired drives for the offered ratings. The new products will be sold and supported exclusively through the global Cat dealer network and the motor products will begin to become available for order during the third quarter of 2015 with the drives becoming available in 2016.

Cat electric motors and variable frequency drives will be assembled in global locations. As a single-source supplier, Cat Dealers will work with both OEMs and end users to engineer ideal prime power solutions, simplifying their electric power conversion needs for this market.

“In recent years, we have strategically evolved our product and service portfolio to enable us to offer more to our customers, including well-stimulation pumps for the well service market and components & solutions for hazardous locations. With this announcement, Caterpillar Oil & Gas and Cat dealers will be a single source supplier of prime movers, including our existing gas-fuelled engines and the new portfolio of electric motors and drives,” Dunlevy stated. “We recognize the need for our customers to incorporate a range of prime movers in gas compression applications and believe Caterpillar will become the industry’s choice for electric motors and drives, when Cat engines will not fit the application.”

For up to the minute information on Caterpillar Oil & Gas, follow us on Facebook: http://www.facebook.com/caterpillaroilandgas & Twitter: http://www.twitter.com/catoilandgas. For more information on the comprehensive gas compression solutions Caterpillar offers, please visit catoilandgasinfo.com .