Marine Asset Intelligence Detects and Engine Imbalance

What Happened?

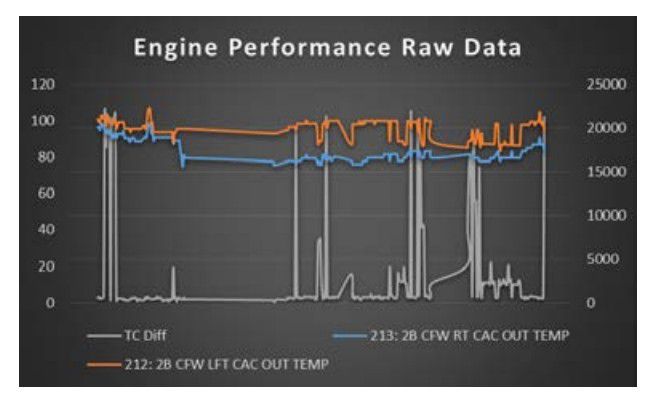

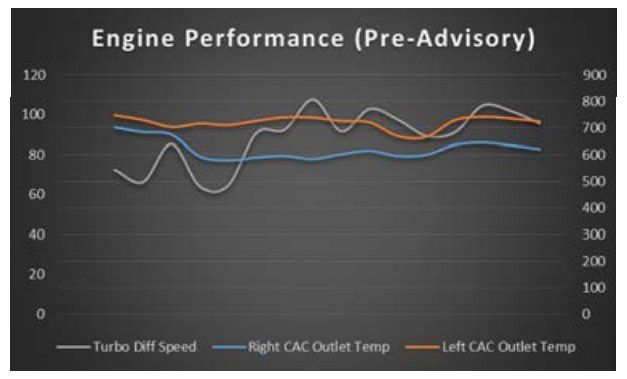

Marine Asset Intelligence uses advanced analytics to qualify raw data into actionable information. Hundreds of thousands of raw data values for each asset are evaluated against a tailored set of rules and intelligently converted into much smaller representative sets of data. Algorithms then determine whether the criteria is met for a fault condition to exist, all without a human in the loop. An MAI Fleet Advisor was notified by the system of an out-of-specification differential speed between the right and left turbochargers on a propulsion diesel engine, resulting in an engine imbalance.

What Was the Underlying Cause?

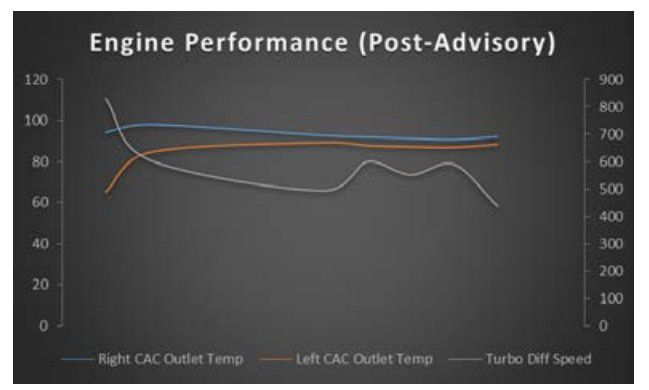

The automated analytics revealed that the right charge air cooler outlet temperature was significantly lower than the left cooler outlet temperature and lower than the acceptable operating limit for that machine state, combined with a large differential between the left and right turbochargers. The charge air cooler functions to provide cooler, denser air to the engine to maximize engine efficiency. Lower air cooler outlet temperature resulted in warmer, less dense air entering the intake manifold. The fuel injection system compensated for the warmer combustion air by reducing fuel and air input, resulting in a lower right turbocharger speed and a greater differential speed between the right and left turbochargers. The root cause for the low charge air cooler outlet temperature was determined to be reduced heat transfer across the cooler due to dirty cooling tube surfaces. An advisory identifying the problem and recommending OEM-approved maintenance procedures were provided to the vessel chief engineer.

What Was the Value to the Customer?

An engine imbalance causes uneven wear across combustion banks, resulting in premature failure of parts and an unplanned top end overhaul. For this engine, the cost of the overhaul would have been $87,500 per cylinder, for a total unplanned maintenance action of $1.4 million. In addition, the imbalance, if left uncorrected, would result in an increase in fuel consumption of 20%, costing the customer an additional $8,500 per day to run that engine.