Se connecter

Bienvenue! Connectez-vous pour personnaliser votre expérience sur Cat.com

Si vous possédez déjà un compte sur une autre application Cat, vous pouvez utiliser ce même compte pour ouvrir une session ici.

Effectuez l'enregistrement dès maintenant

Un seul compte. Pour tout Cat.

Votre compte Caterpillar est le seul compte à utiliser pour ouvrir une session dans les services et applications que nous offrons. Magasinez des pièces et des machines en ligne, gérez votre parc de véhicules, passez en mode mobile, et plus encore.

Informations sur le compte

Paramètres du chantier

Sécurité

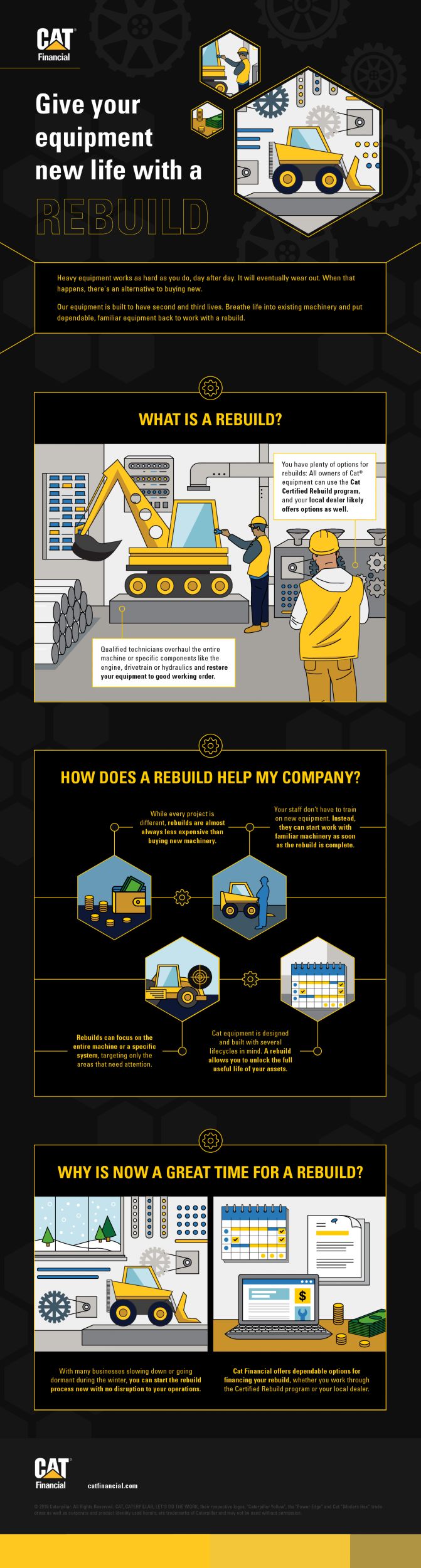

Extend the Life of Your Equipment with a Rebuild

THE COST-EFFECTIVE OPTIONS FOR REBUILDING YOUR CAT® MACHINE

On the job or at home, we're conditioned to view replacement as an alternative to repair. And while it might not make sense to repair inexpensive, readily available items like a blender, wall clock or keyboard, we can all agree that heavy equipment is different.

An equipment rebuild takes the special nature of heavy equipment into account. It recognizes the costs of owning and operating machinery and the value that a familiar, dependable asset brings to your business. When you opt for a rebuild, your business can greatly extend the useful life of equipment for a lower price than purchasing a new piece of equipment.

The approach of winter - a time when your business may operate on a reduced schedule - is a great time to start considering the benefits of an equipment rebuild. Whether you have a specific piece of equipment that's reaching the end of its overall lifecycle, want to improve a specific core system or simply learn about the available options, understanding the value of rebuilding your Cat® equipment helps you make more informed choices.

Breaking down the rebuild process

Every rebuild is unique to the business and piece of equipment involved, but the major benefit of this process is a cost-effective alternative to buying new equipment. Because Cat machinery is designed with more than one functional lifecycle in mind, a rebuild can be an especially good decision in terms of both productivity and finances.

Your local Cat dealer works with certified technicians who have the know-how, skills and expertise to consistently and confidently rebuild your equipment. That's true whether it's an articulated truck, wheel loader, another type of Cat equipment or a major component of your Cat machine.

UNDERSTANDING THE CAT CERTIFIED REBUILD PROGRAM

Cat Certified Rebuilds are an effective option for rebuilding your machinery, offering an exceptionally high level of service and expertise for this detailed project. We offer five options designed to align with your specific objectives:

- Certified Rebuild: This option is the most extensive: a complete rebuild that covers the entire machine. Any worn or damaged parts are replaced while introducing critical engineering updates that further boost performance.

- Certified Hydraulic Rebuild: When the rest of your equipment is functioning properly, this option allows you to update and refresh the hydraulics - a key improvement for a variety of machines.

- Certified Power Train Rebuild: A power train rebuild covers everything from the radiator to wheels and sprockets, extending your machine's useful life and restoring performance.

- Certified Engine Rebuild: An engine rebuild maximizes your investment in the durability and performance you've come to expect from Cat equipment.

- Certified Machine Component Rebuild: This option focuses on restoring transmissions, torque converters, axle assemblies, final drives and similar components.

With support from the largest dealer and parts distribution network in the world and effective warranties and coverage designed with the needs of business owners in mind, you can be confident that your rebuild will significantly extend the lifecycle of your equipment. Caterpillar carefully engineers multiple lives into every piece of Cat equipment. The Certified Rebuild program allows you to take full advantage of this design specification.

10 REASONS TO CONSIDER A REBUILD RIGHT NOW

An equipment rebuild can be a great option for your business regardless of time of year. But the transition from fall to winter can offer some unique benefits in terms of rebuilding equipment that aren't available during the warmer times of the year, when many companies that use equipment have the heaviest workload. Let's look at 10 reasons why you should consider a rebuild option sooner than later:

- Put your rebuilt equipment to work as soon as possible: The sooner you start the rebuild process, the sooner certified technicians can do their jobs and return your equipment to you. That means it's back on the job quickly, ready to work on the next project.

- Take advantage of the slow season: If your business doesn't do as much work or takes a few months off during the winter, you can have your equipment rebuilt with minimum disruption to your operations.

- Consider your options: Not sure if your equipment needs a total rebuild or a more specific rebuild on a certain system? You can do the legwork, make your decision and contact your local Cat dealer to get your project started.

- Effectively utilize employee skills and experience: You know your staff are qualified to operate your current fleet of equipment. A rebuild means no downtime for training on new systems or adjustment periods before operators are ready to go to work.

- Budget better: Making a decision now allows you to make choices about budget needs and understand how a Certified Rebuild can save money versus buying new equipment.

- Plan farther out: Worried about downtime? An equipment rebuild allows you to make plans far into the future about resource allocation with the confidence that a thoroughly refurbished piece of equipment offers.

- Start a longer process: Does your business have several pieces of heavy equipment that are candidates for Certified Rebuilds? Start the first project now and see benefits as soon as your machinery is returned to you.

- Avoid a new equipment purchase: New equipment is undoubtedly effective, but can also be expensive. If your company isn't ready to take this step, a Certified Rebuild can be exactly what you need.

- Keep your workers happy: Allow your staff to do what they do best with the equipment that they're most comfortable using.

- Find effective financing options: Cat Financial offers financing that helps you budget for and realize the benefits of rebuilt equipment, helping to spread out the cost of the project.

Talk to your Cat dealer about our current offers that can help with your machine rebuild.

Additional Articles

Want more insights into equipment financing and protection, answers to common questions and tips for running a financially smart operation? Check out these articles.