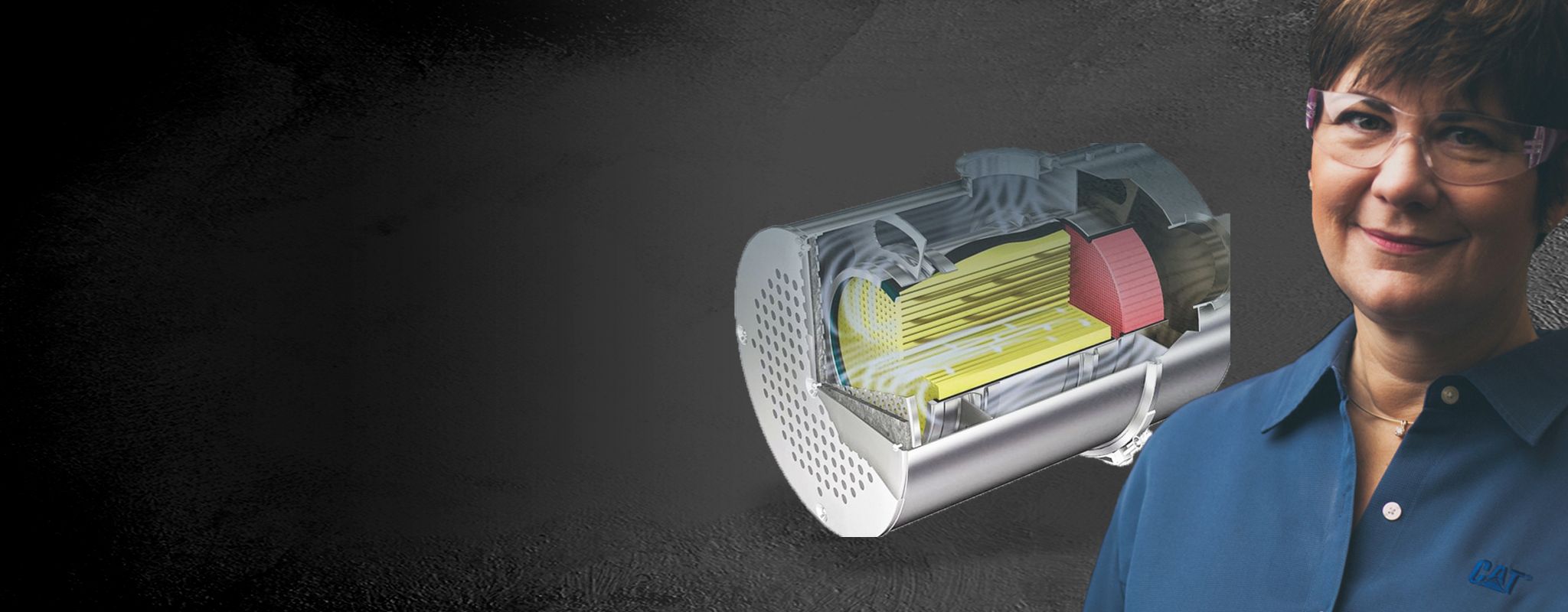

Deepen your DPF Knowledge

If you haven’t already, you’re going to be hearing a lot about DPFs (diesel particulate filters) as emissions standards evolve. EU Stage V emissions standards are driving the use of these aftertreatment devices, and with many engine manufacturers aiming to offer one common platform globally, you’ll find them used in more than just European markets. When you’re evaluating DPFs for your application, here are three things to keep in mind:

Not All Regeneration Systems are Created Equal

DPFs capture and store carbon and soot to reduce particulate matter emissions. The trapped material must be emptied or burned off periodically to “regenerate” the filter. That regeneration process may differ from engine manufacturer to engine manufacturer — so be sure to ask about these factors:

- Load requirements or limitations: Does the engine need to operate at or above a certain load for regeneration to work properly? If so, your customers, particularly those working in “light” applications, may be forced to buy a load bank — which could double the cost of the engine.

- Operator involvement: What responsibility, if any, does the operator have for making sure regeneration happens when and as it should?

- System life: Is the regeneration system designed to last for the life of the engine? If not, consider the downtime, costs and inconvenience associated with replacement.

Choose a System That Favors Operators

A shortage of well-trained, experienced equipment operators is presenting big challenges across industries these days. Don’t let DPF regeneration add to a machine’s complexity. Instead:

- Look for systems that are “transparent”: That means regeneration happens in the background with no operator interaction. Ideally, there should be no buttons to push, no switches to throw and definitely no need to park the machine to take action.

- Make sure the system can regenerate in any environment: Some systems require operators to take different actions in certain applications, such as working inside a flour mill or in a corn field where temperatures can’t get too hot. That can be confusing for the operator and potentially dangerous.

Telematics, Genuine Parts and Fluids Matter

Engine manufacturers will tell you ALWAYS to follow guidelines set forth in the operation and maintenance manual. But the addition of aftertreatment systems makes even the most durable engines more sensitive to abusive operation or missed maintenance. That's why it's critical to make sure your customers know the following:

- Saving a couple dollars buying a cheaper off-brand isn’t worth the risk of damaging an expensive regeneration system. Sticking to a service schedule is critical, too. Having access to a dealer network with fast parts availability and plenty of service shops and trucks makes a big difference in ensuring the right maintenance gets done at the right time.

Buy genuine oil, filters and parts

- When engines are connected to a telematics system, your customers (and their dealers) can keep an eye out for operator abuse and keep preventive maintenance on track. Spotting problems before they turn into failures saves money and downtime.

Take advantage of telematics