- Reach up to 20 m (65’6”) with a 3300 kg (7,275 lb) demolition tool.

- Whatever your demolition task, Cat® offers a complete range of tools ready for work. Each Cat demolition attachment is designed as an extension of the machine to help you get the job done safely, quickly, and profitably.

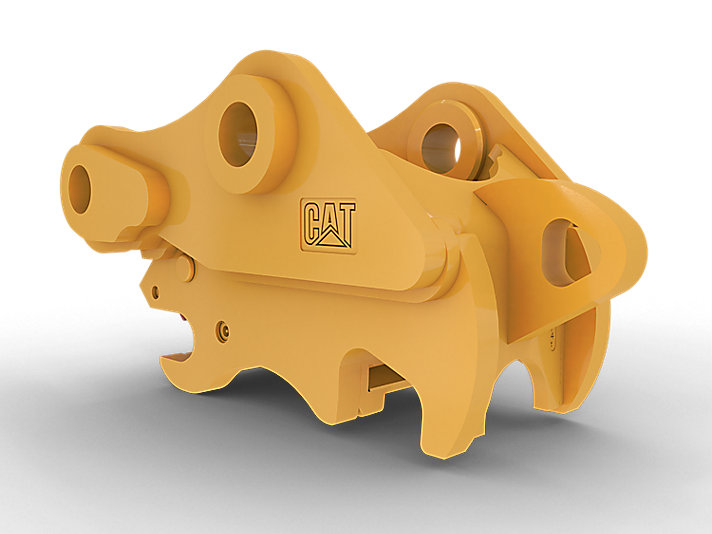

- Our one-stop-shop attachment lineup includes all-purpose buckets, mechanical quick couplers, hydraulic quick couplers, full hydraulic quick couplers, scrap shears, multi-processors, pulverizers, crushers, demolition and sorting grabs, contractor grapples, hammers, and rotary cutters.*

- The Cat® PL161 attachment locator allows you to track attachments across all worksites, reduce the number of lost attachments, and plan for attachment maintenance and replacement. The work tool recognition feature automatically adjusts machine settings based on the selected tool.

- The Cat active stability monitoring system continuously informs operators of the work tool's position within the safe working range and warns when the stability limit is approaching.

- Choose your undercarriage—a 3 m (3'10") transportation width with fixed or hydraulic variable gauge undercarriage or a 3.4 m (11'3") wide for extended stability on the job.

- Standard rearview and right-hand side view cameras give clear views on the monitor.

- The C7.1 engine can run on biodiesel up to B20 and meets EU Stage V, U.S. EPA Tier 4 Final, and Japan 2014 emission standards.

- Match the excavator to the job with three power modes – Power, Smart, and ECO. Smart mode automatically matches engine and hydraulic power to working requirements, providing maximum power when needed and reducing power when it isn’t to help save fuel.

- The high-efficiency hydraulic reversing fan cools the engine on demand to help reduce fuel consumption.

- Cat technologies increase operating efficiency to lower operator fatigue, operating costs, and fuel consumption.

*Not all attachments are available in all regions. Contact your Cat dealer for more information.

When you buy Cat® equipment, you get more than the machine. You’re also getting the support of a best-in-class dealer network backed by a range of flexible solutions, technology, tools, and more.

When you work with your local Cat dealer, you'll be supported by one of the industry's most extensive, knowledgeable dealer networks. Comprised of 160 independent dealers, the Cat Dealer Network serves 197 countries with thousands of branches around the globe.

It’s more uptime, cost-saving service and repair options, quality parts, and precision components. It’s all about support built around your success.

Ask your Cat dealer today about the many services that help you do your work your way.

- The importance of buying genuine Cat parts.

- Designed by Caterpillar engineers to the exact specs of your Cat equipment.

- Rigorously tested to ensure maximum performance.

- Covered by a 12-month warranty.

- Cat Inspect – Work made easy.

- Record real-time inspection data.

- Simplify inspections and reporting.

- Easy-to-read results all in one place.

- Cat Ground Engaging Tools (GET) – Longer wear. More work.

- GET for every machine and application.

- Tools to extend life and track GET lifecycles.

- Bucket rebuild options for optimal performance.

- Cat Hydraulic Components – Durability quality you can work with.

- Flexible options – New, reman, exchange, rebuild or repair.

- Expert diagnostics, testing, and contamination control.

- Buy in-store, online, or on your mobile device.

- Cat Hose Service – Fast, safe—to get you back to work.

- Hoses and couplings for most makes and models.

- OEM database ensures an exact fit.

- Industry-best tooling, training, and assembly standards.

- Cat Certified Rebuild – An investment that works. Again, and again.

- Better-than-when-new performance at a fraction of the cost.

- Performance, safety, and technology upgrades and enhancements.

- Full warranty coverage, Customer Value Agreement, and special financing.

- Cat Remote Services – Work done in a flash.

- Cut downtime for updates and service.

- Install the latest machine software remotely.

- Troubleshoot issues before a technician arrives.

Learn more at

https://parts.cat.com/

- The Cat® C7.1 TTA engine meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Auto Engine Speed Control helps reduce unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- Cat Grade technologies combine advanced guidance with optional automated machine control helping you reach grading targets while reducing fuel burn and greenhouse gas emissions by improving efficiency, job site productivity, and accuracy.

- Cat® Payload for excavators provides on-the-go material weighing which helps reduce fuel burn by improving loading efficiency, job site productivity, and eliminating trips to the scale.

- Cat® 2D E-fence keeps the front linkage within a predefined work area to avoid hazards such as traffic - not only helping keep personnel safe but also helps you avoid repairs, downtime, and costly job site fines.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

*Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).

**Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels

.