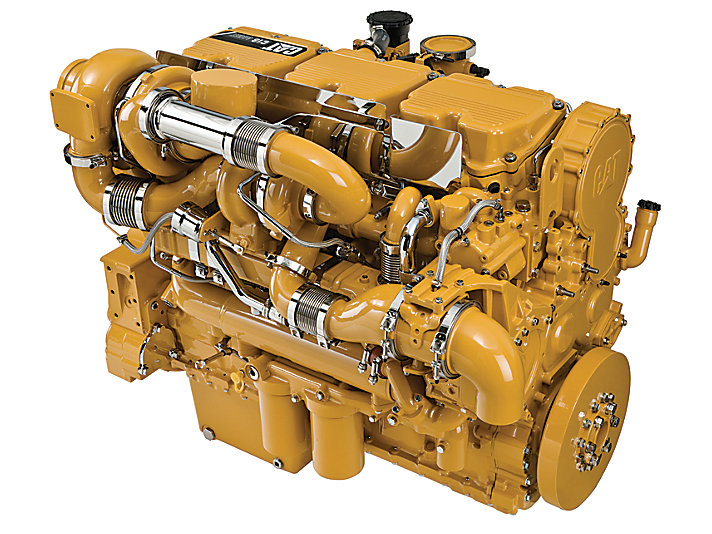

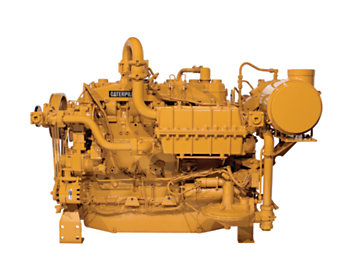

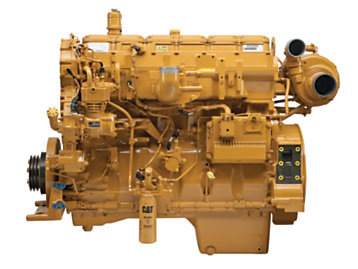

- Designed to meet U.S. EPA Tier 4 Final emissions requirements. - On-engine NOx reduction system with optimized piston, ring, liner, and fuel system configuration to reduce NOx while minimizing in-cylinder sooting- Aftertreatment features diesel oxidation catalyst- Meets Tier 4 Final emissions requirements four years early, achieving environmental benefits earlier than required

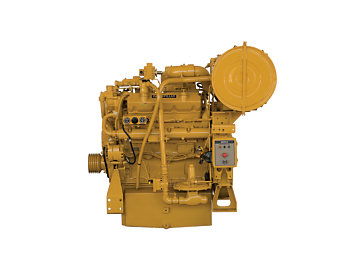

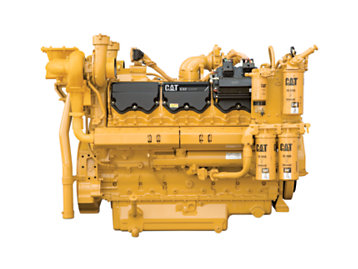

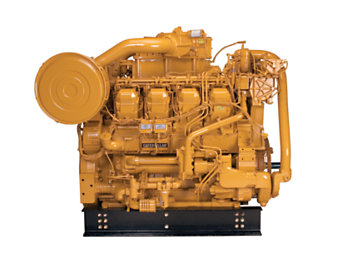

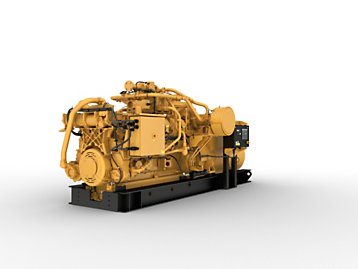

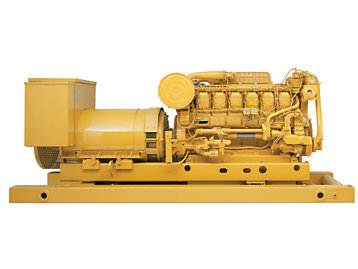

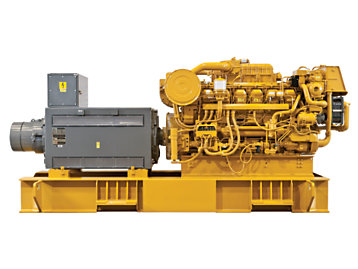

- Proven reliability and durability- Broad operating speed range- High power density- PTO drive options provide flexible access to auxiliary power for pumps and other needs

- Maintenance-free aftertreatment- Optimized fuel consumption- 250- to 500-hour oil change intervals enable low maintenance costs

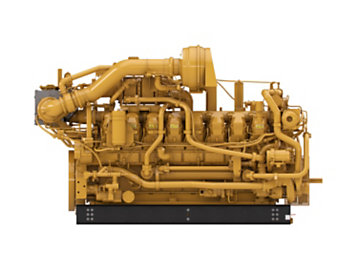

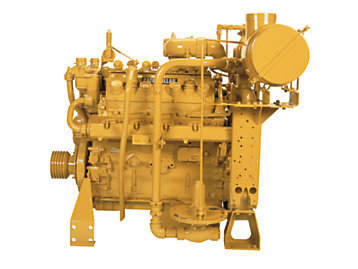

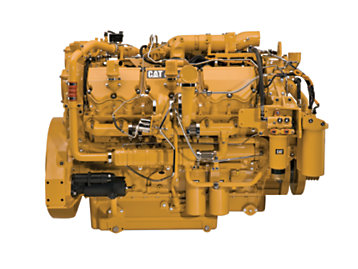

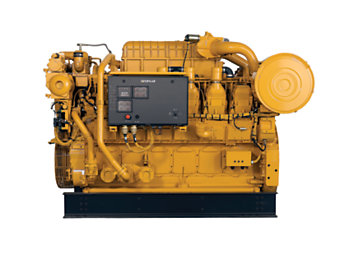

ADEM A4 control system providing integrated ignition, speed governing, protection, and controls, including detonationsensitive variable ignition timing. ADEM A4 has improved: user interface, display system, shutdown controls, and system diagnostics.

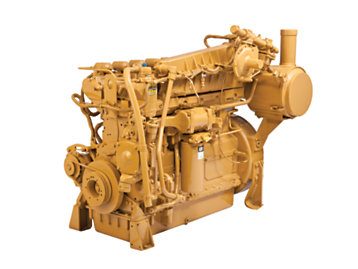

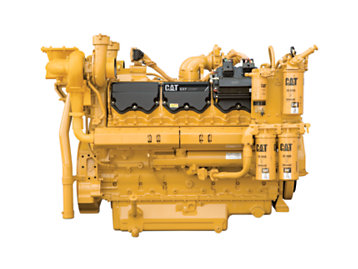

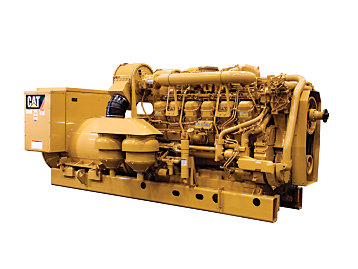

For any petroleum application, trust Caterpillar to meet your exact needs with a factory custom package. Cat engines, generators, enclosures, controls, radiators, transmissions, aftertreatment solutions — anything your project requires — can be custom designed and matched to create a one-of-a kind solution. Custom packages are globally supported and are covered by a one-year warranty after startup.

Requires Ultra Low Sulfur Diesel (ULSD) containing a maximum of 15 ppm sulfur, and new oil formulations to support the new technology. Designed to accommodate B20 biofuel.

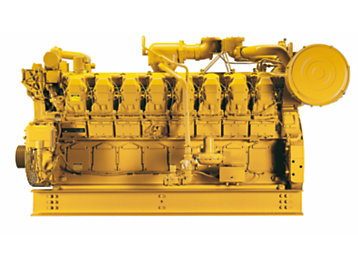

- Caterpillar has a full line of engine-transmission packages that can be fully integrated with your axle, hydraulics, and operator interface.- C18 ACERT™ Caterpillar optimized transmission matches: CX35-P800

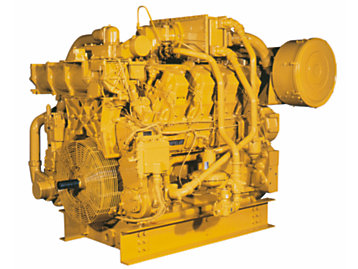

- More than 2,200 dealer outlets- Cat factory-trained dealer technicians service every aspect of your petroleum engine- Cat parts and labor warranty- Preventive maintenance agreements available for repair-beforefailure options- S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine:- Internal engine component condition- Presence of unwanted fluids- Presence of combustion by-products- Site-specific oil change interval

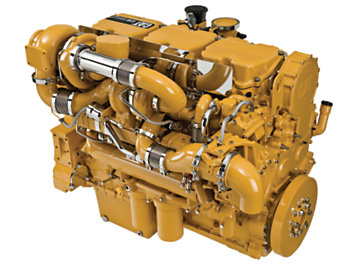

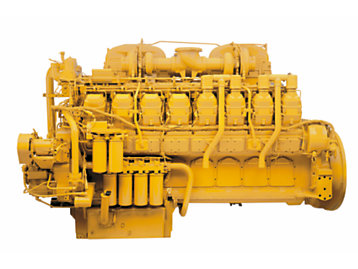

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.- Cast engine blocks, heads, cylinder liners, and flywheel housings- Machine critical components- Assemble complete engine

For all your petroleum power requirements, visit www.cat.com/oilandgas.