Flex sought reliable, efficient energy to power multiple facilities in Guadalajara and Tijuana. Working with Cat dealer Tracsa Energia, Flex commissioned three cogeneration plants at its facilities in Mexico to produce power and air conditioning.

Learn MoreWhen Nexperia Philippines, Inc. began to worry about the damage a prolonged power outage could do to the materials in its warehouse, it looked to Cat® dealer Monark Equipment Corporation to install and commission two Cat C13 diesel generator sets to deliver reliable power to its facilities.

Learn MoreBased in Kosów Lacki, Poland, the Zakrzewscy Meat Processing Plant sought a new energy source after electricity prices on the Polish energy market skyrocketed. Working with local Cat® dealer Eneria Cat, Zakrzewscy installed a Cat generator set and combined heat and power system to insulate the plant from unstable utility costs.

Learn MoreFinding reliable and cost-effective interim power solution in a developing area with an equally developing grid was the challenge. The solution – a Cat genset providing prime power for the whole facility, with a planned conversion to standby use when the power grid stabilizes.

Learn MoreWith the rise of the Internet, demand for newsprint has decreased and many mills have closed down. See how an onsite power plant using Cat® G16CM34 generator set power helps one paper mill continue to thrive in a declining industry.

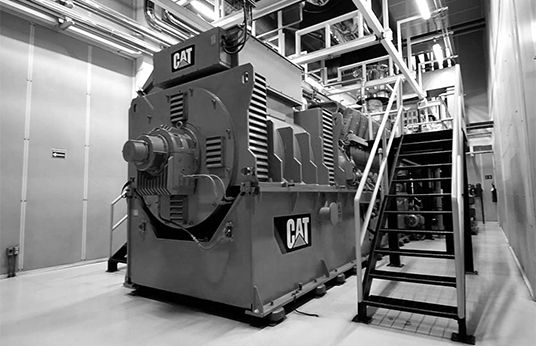

Learn MoreMexico’s largest integrated steelmaking company produces 5 million metric tons of liquid steel annually for hot- and cold-rolled coil. Their challenge was met through Cat CG260-16 gas powered engines.

Learn MoreCompany officials determined they could reduce electrical costs by producing their own power during evening hours rather than relying on the utility companies. In 2009, Conduspar installed a Cat® 3412 diesel generator set devoted to standby power for a copper oven used in the process of melting and extruding copper into wire. Later, the company added two Cat C32 ACERT™ diesel generator sets to supply standby power for overall factory operations. These three generator sets also allow Conduspar to engage in peak shaving activities during evening hours when power is most expensive.

Learn MoreThe Endurance Facility started as a concrete pad with a basic enclosure for a pre-production C175-16 3MW diesel generator set. In 2011, it grew to include a then pre-production G3520E generator set and then - prototype G3516H genset - both powered by natural gas. The facility also includes a pre-engineered structure that houses the entire electrical and mechanical infrastructure required to tie the gensets into LEC’s electric utility feed.

Learn MoreGZBC has completed testing of the Cat generator sets and is in the process of completing their phased integration into the power supply of the brewery. Caterpillar and CEL were able to design the CCHP system and its installation to meet the customer's unique demands. The new generator sets make use of the plant's recovered biogas to generate power and would transfer waste heat into a cooling source.

Learn MoreKyocera uses the waste heat from its cogeneration facility to feed the chillers that air condition the plant. Beyond power consumption considerations, the plant requires low humidity and an optimum furnace temperature range for the manufacture of its ceramic packages and other sensitive products. Originally, Tanaka investigated the possibility of using turbines for cogeneration; however, diesel generators proved to be a better match for Kyocera's chilled water needs.

Learn MorePlainville Electrical Products Company (PEPCO) has been designing and manufacturing electrical control systems and distribution panels for commercial and shipboard use since 1922. Many of these systems have been installed on U.S. Navy ships and large yachts. PEPCO has also designed a number of power management and generator control systems for utility applications. With experience in the utility market and extensive knowledge of control systems design, the PEPCO engineering team combined these areas of expertise to create a cogeneration plant that would be ideal for manufacturing and commercial facilities, including hotels, hospitals, data centers and other facilities with large heat loads. The waste heat from the generator powers two absorption chillers. These combination chiller/heater units provide 95 percent of the facility’s heating and cooling needs. By harnessing this waste heat, the system efficiency is increased from 35 percent to about 70 percent.

Learn MoreWith the largest and most modern freeze-drying capabilities in Brazil, Liotécnica depends on a consistent flow of power to maintain its perfected freeze-drying methods. With attractive equipment financing options available from Cat® Financial, the company decided to purchase two diesel generator sets for reliable standby power and peak load shaving.

Learn MoreThe Kalasin Starch factory uses the fruit of the tapioca plant to produce starch for food and medical products. The organic waste generated from the starch production process is channeled to an anaerobic digester, where it generates methane gas that will be used to fuel the Caterpillar gas generator. Approximately 12,000 Nm3 of digester gas is generated daily and will be fed to the gas generator for power generation. The power generated from the biogas-fueled generator will be sufficient to meet the entire power requirement of the plant.

Learn More