Weights - Approximate

| Nominal Rated Payload | 256 ton (US) 232 t |

| Rated Gross Machine Weight | 846240 lb 383848 kg |

| Chassis Weight | 268929 lb 120563 kg |

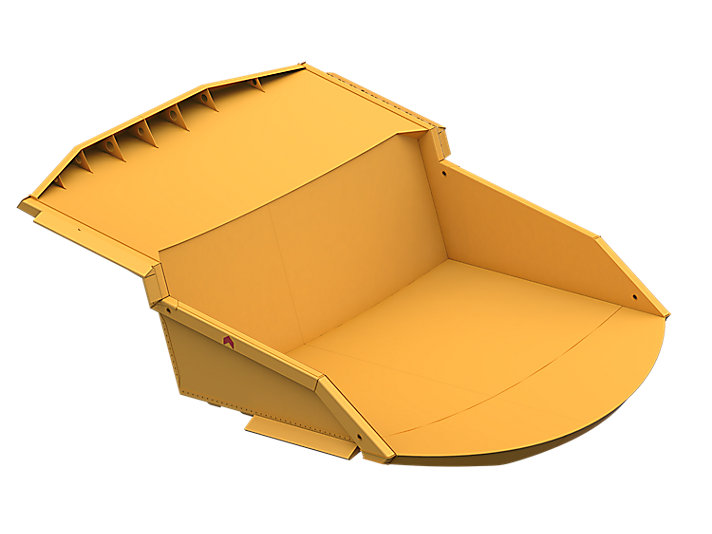

| Body Weight | 68564 lb 31100 kg |

| Note (1) | Consult your tire manufacturer for maximum tire load Consult your tire manufacturer for maximum tire load |

| Note (2) | Chassis weight with full fuel and fluids, standard & mandatory attachments, hoist, body mounting group, rims, and tires. Chassis weight with full fuel and fluids, standard & mandatory attachments, hoist, body mounting group, rims, and tires. |