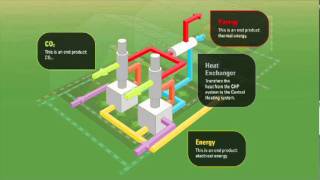

Combined heat and power systems provide a profitable and sustainable solution for greenhouses. By generating thermal energy and electrical energy simultaneously, a CHP system can yield a fuel efficiency rate over 90% versus the typical boiler efficiency of 40-50%. Typical payback on these systems is less than 3-4 years.

Any Cat natural gas-fueled engine can be configured specifically for applications involving heat recovery. The engine drives a Cat commercial greenhouses generator to produce electricity, while jacket water and/or exhaust cooling circuits are fed through heat exchangers to transfer the waste heat from the engine to a hot water holding tank. That hot water is stored and used to keep the greenhouse warm. Oxidation catalysts can be used to remove carbon monoxide, and a urea-based SCR system is employed to reduce NOx to just a few parts per million. The result is an exhaust gas so clean it is piped to the greenhouse plants' roots as a fertilizer, boosting farmers' yields.

Since sizing based on heat load is the key driver, the electricity produced at a greenhouse often exceeds the local demand. Many countries throughout Europe incentivize high-efficiency electric power generation via production credits and most electricity produced is exported to the local grid. In other parts of the world, grid unreliability and pure economics are driving greenhouse agriculture toward similar solutions.

Caterpillar provides customized CHP package proposals, including the required mechanical equipment and controls to capture and transfer the engine thermal energy to a greenhouse facility. In addition, Caterpillar offers the required exhaust emissions aftertreatment, utility grade paralleling switchgear, and controls to sell excess electricity generated to the local electric grid.

The total energy cost savings of such systems can more than offset the total owning and operating costs, delivering a payback in as little as two to three years, depending on local energy pricing and policies.

Seacliff collects vegetable and animal waste from nearby farms and greenhouses, generating enough biogas to fuel a power plant designed and supplied by the local Cat® Dealer, Toromont Cat Power Systems. The facility can currently process up to 40,000 metric tons of organic waste per year, which will increase to 100,000 metric tons once Phase II is complete. At that time, Seacliff will have the largest energy producing anaerobic digester in North America.

Learn MoreDue to the technology being used for abundant production in greenhouses, AS Grüne Fee Eesti is a major consumer of electric power in Southern Estonia. The Cat G3516A generator sets produce 75% of the required power to manage the greenhouse. The generator sets run parallel with the grid, and AS Grüne Fee Eesti purchases 25% of their required Power generation from the local utility.

Learn MoreProducing reliable power from 830 to 1250 ekW at 60 Hz, our C32 diesel generator sets are made to meet your mission critical, continuous, standby and prime applications. We've designed each to ISO 8528-5 transient response requirements and to accept 100% rated load in one step. Generator sets range from low fuel consumption systems to EPA Stationary Emergency (Tier 2) certification.

Learn MoreFrom natural gas-fueled combined heat and power (CHP) systems and emergency power for facilities, to renewable biogas energy to support the local grid, or electricity generated from coal mine gases, Caterpillar has a wide range of reliable gas power solutions.

Learn More