If you already have an existing account with another Cat App, you can use the same account to sign in here.

One Account. All of Cat.

If you already have an existing account with another Cat App, you can use the same account to sign in here.

Account Information

Site Settings

Security Settings

Read Profile

Product Overview

Cat Engine Overview

Gallery

Related Profiles

Power Profile

CUSTOMER:

GeoQuip Power Systems/HPSI

PRODUCT:

HPSI Model 500 Vibratory Hammer

LOCATION:

Kansas City, Missouri

SCOPE OF ENGINE USE:

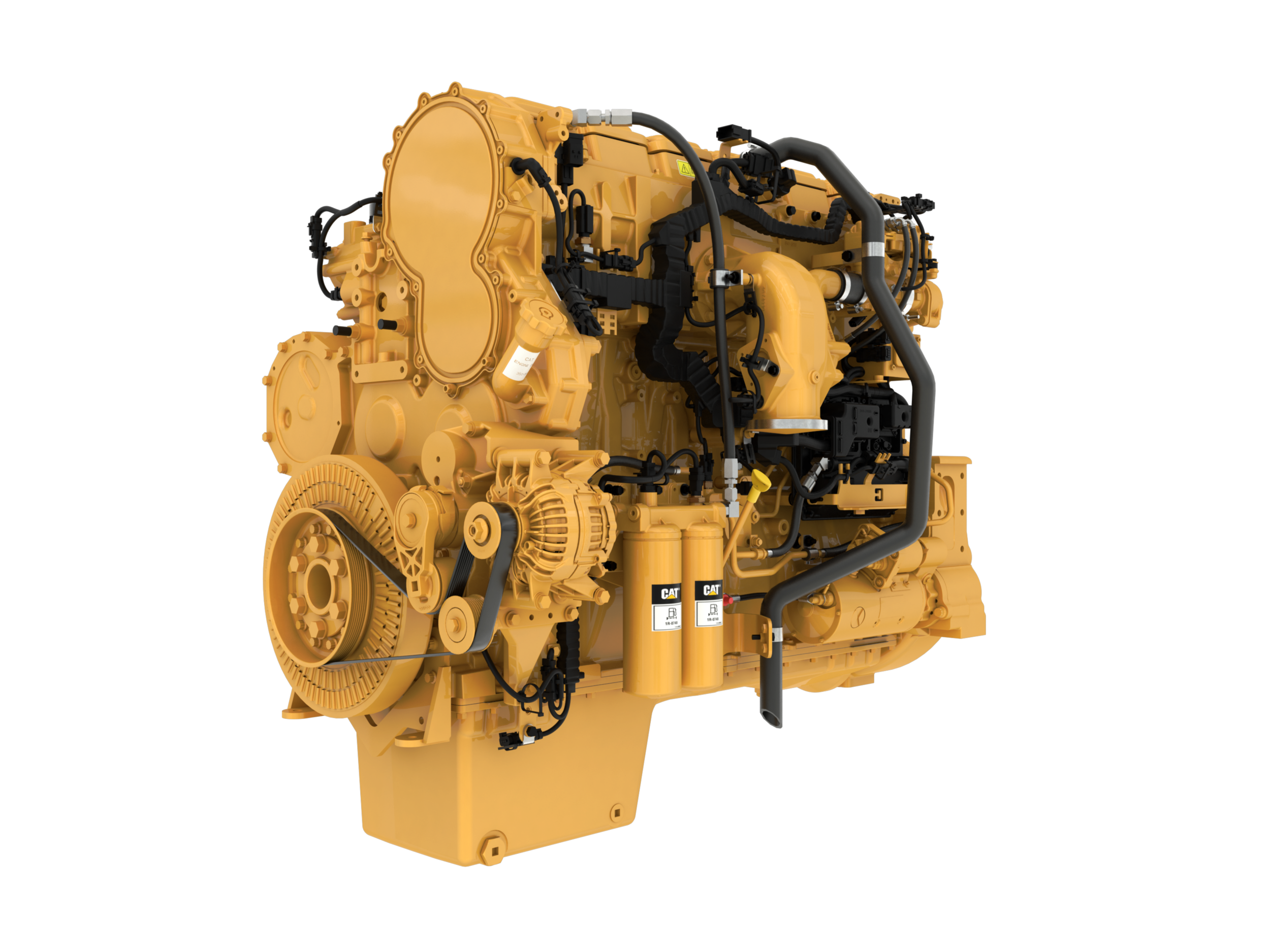

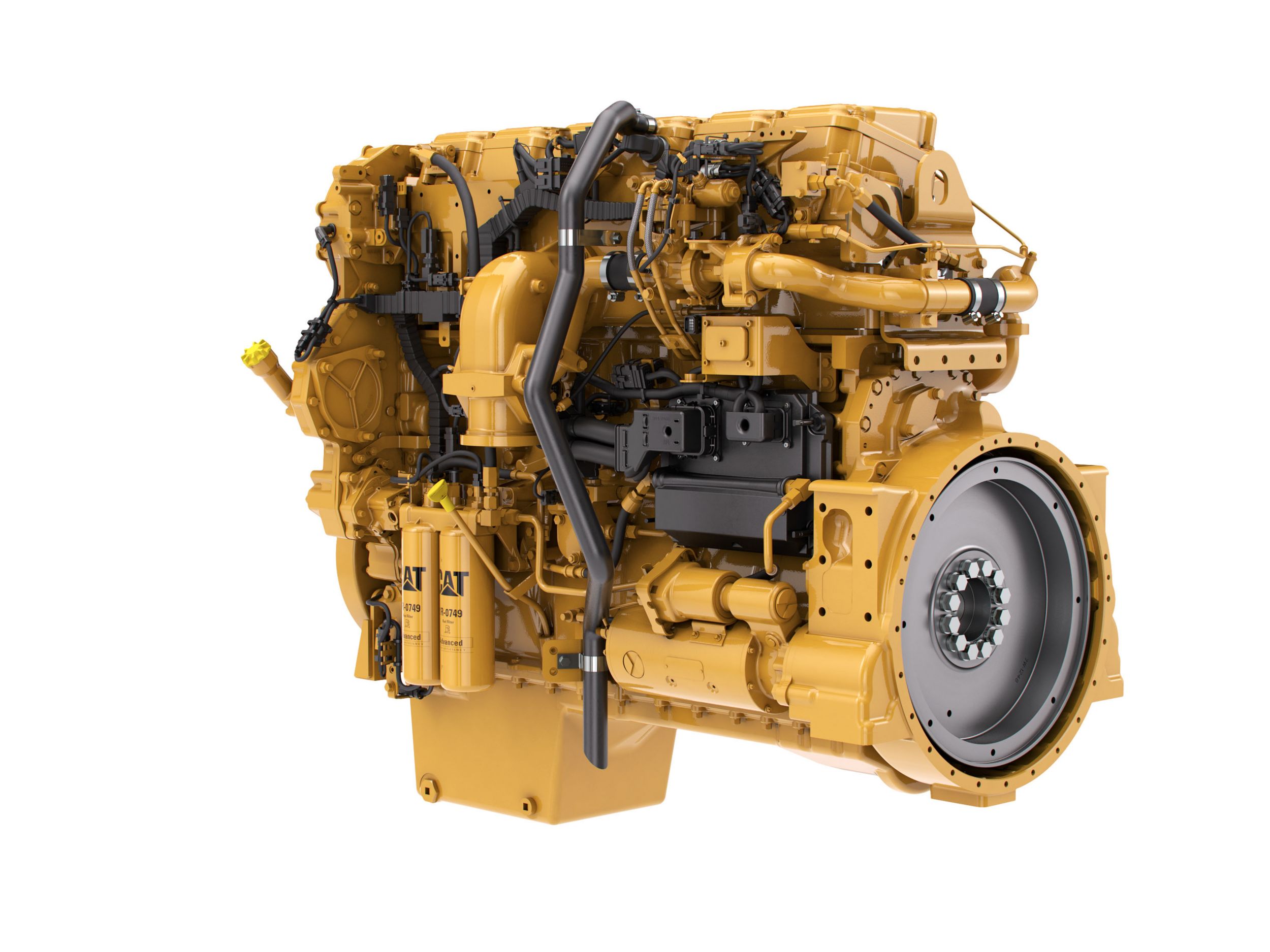

Cat® C18 Tier 4 Final, Stage V Industrial Engine

HPSI Model 500 Vibratory Pile Hammer From GeoQuip Power Systems

Across the United States, GeoQuip Power Systems/HPSI vibratory hammers do what only a select group of specialized equipment can: These crane-suspended machines drive or extract massive sheet piles, king piles and pipe piles for heavy civil and marine projects. The vibration liquified the soil to allow colossal piles in excess of 150 feet to easily plunge deep into the ground, creating deep and sturdy foundations for bridges, tunnels and other infrastructure.

Founded in Kansas City, Missouri in 1980, the company originally focused on manufacturing custom hydraulic winches, power units and augers. After seeing a need in the market for a high-quality vibratory hammer, HPSI launched their first model in 1990. After adding vibratory hammers to its existing product lines, HPSI quickly established dominance in the marketplace.

If It’s Not Broke, Don’t Fix It

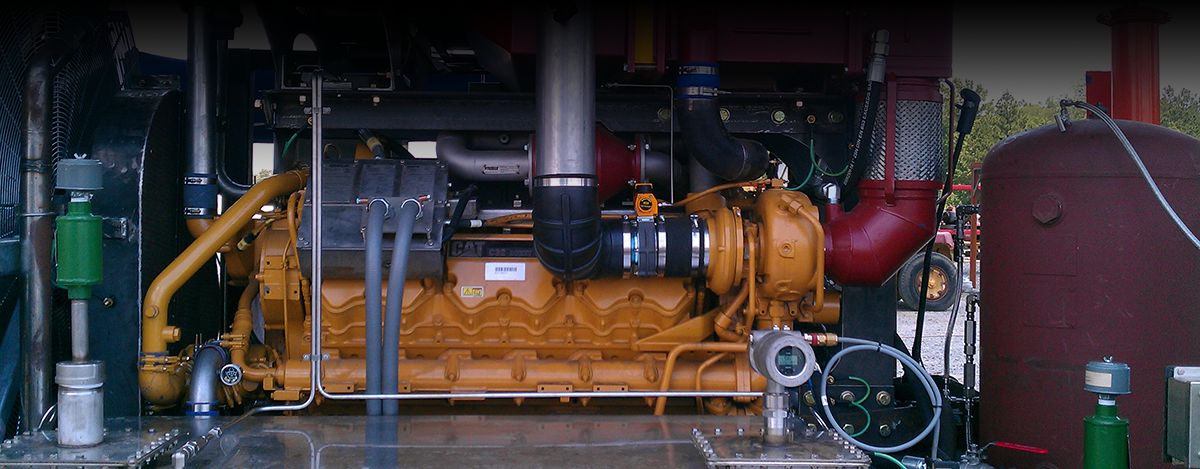

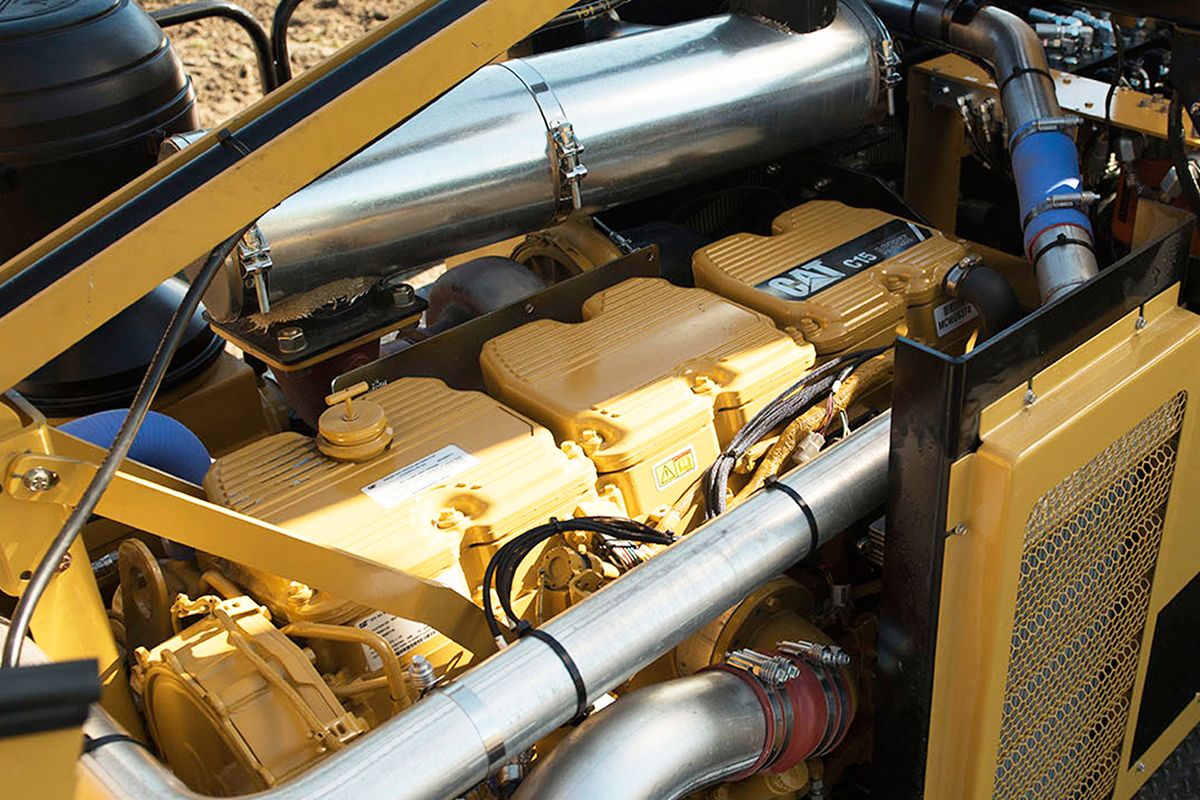

All of HPSI’s products are manufactured in the United States with Class A domestically sourced materials, including its flagship machine: the HPSI Model 500 Vibratory Sheeting Hammer. Recently, the team has upgraded the Model 500’s long-standing, industry-leading design for the modern age with a new digital display panel, custom integrated coolant system and power pack design changes for continued top performance.

“When the driving gets tough, you need to maintain drive pressure. By taking our original design and modernizing it, we’re still able to maintain hydraulic pressure and drive force better than our competitors, even with what appears to be a smaller hammer on paper.

Going Pound for Pound

While the Model 500 is designed to drive materials into soft soils, what lies below is often unknown. HPSI works with geotechnical engineers to mitigate potential piling problems before they arise by modifying attachments or building custom accessories that best prepares every customer for their unique project. From the type of crane being used on the job to the presence and depth of water (or lack thereof) on a jobsite, HPSI factors every variable into each custom solution. That level of customization sets HPSI apart.

“Our customers know that they need more than just a high-quality product; they need expert support to provide custom solutions. We’re willing to tackle these specific needs because we understand how unique the requirements for each project can be,” explained Martin Terwilliger, who is based out of the company’s Chesapeake, Virginia location.

Hammering Out the Details with Cat Dealer Support

HPSI has always relied on Cat® engines for its products. Carter Machinery was chosen to develop several of the Model 500’s new features, including its upgraded power pack. The machine is built around its Cat C18 industrial diesel engine, which reaches up to 755 horsepower. The engine also meets Tier 4 Final and EU Stage V emissions standards. Both engineering teams strategically chose a larger engine to pack in the necessary power to generate the 180 tons of dynamic force that the Model 500 is capable of – that’s enough force to shake about 50 vehicles!

“A lot of our competitors provide underpowered engines that make their hammers less effective, especially in difficult driving conditions. The higher horsepower and torque we realize from using Cat engines allows our hammers to provide peak performance on the pile,” said Terwilliger.

Caterpillar will be there through every shake, rattle and ram for dedicated service. Any and all engine maintenance needs are backed by the nationwide Cat dealer network, keeping these vibratory hammers piling on with confidence.

-

Caterpillar Jobsite & Equipment Safety Offerings

Learn about Caterpillar’s free safety resources, including safety consulting and education services, for technicians, operators, and other jobsite workers.

Learn More -

Financing & Insurance

At Cat our finance and insurance representatives can provide the best solution for your business. Find out how our representatives can help you get the most out of your investment, whether you need to finance construction equipment, a boat with a Cat engine or a power supply backed by a Cat generator.

Learn More -

Job Site Solutions

Caterpillar's Job Site Solutions Fleet Management team can partner with you to help manage equipment from acquisition and fleet maintenance, to productivity and operator efficiency, to resale and disposal, freeing you to run and operate your fleet with less worry and more efficiency.

Learn More

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.