A LEGACY OF LIQUID TRANSFER

How The New Cat® C13D Is Fueling A Family Business

Jeremy Puck has always been driven by innovation. Growing up in the 1980s, he watched his father launch Puck Enterprises, a custom manure and hay baling business housed on the Century farm in Manning, Iowa. When Jeremy fully joined the family business post-college, he spurred its growth into a full manufacturing facility so Puck could apply manure faster and more efficiently. Over the decades, Puck has grown globally from a barn with four employees to a team of 240, supplying manure application equipment to the majority of the Northeast of America and large parts of Eastern Europe.

“We’ve been a pioneer in trying to find new, innovative ways to get liquid to the field faster, safer and more efficiently,” says Jeremy Puck, now the President and CEO of Puck Enterprises.“ One of the key components to that is adding horsepower to the equation.”

Flowing forward

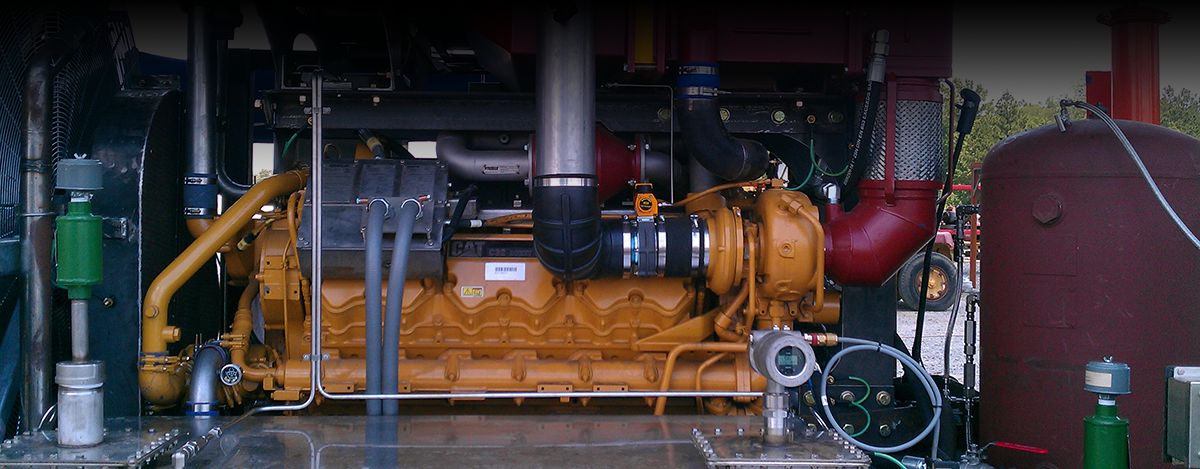

Puck first collaborated with Ziegler Cat in 2018 for help with transitioning their engines to Tier 4, Stage V. Currently, Puck uses multiple Cat® engines, ranging from the C4.4 on smaller agitation units to the C18 on their largest pumps. In 2017, they successfully utilized a C9.3B prototype for an entire winter in northern Alberta, running it in permafrost diamond mines that were -40 °F.

“Usually engines don’t survive there,” notes Jeremy Puck, President and CEO of Puck Enterprises.“ So, the fact that all the systems performed like they needed to really sold us.”

After the C9.3B exceeded expectations in Alberta, Jeremy kept his eye out for new pilot opportunities. When the new Cat C13D was ready to be tested in the field, he jumped at the chance.

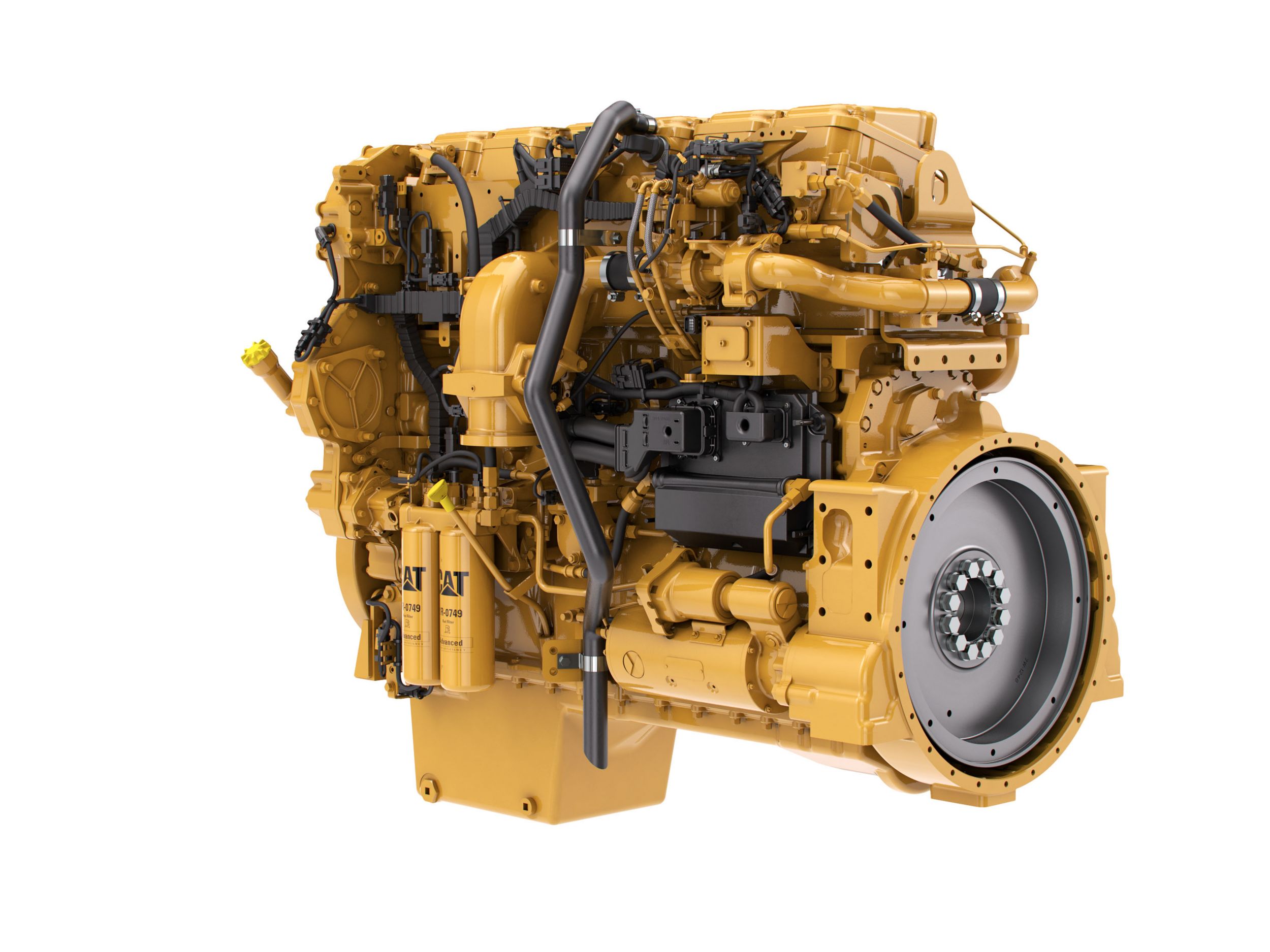

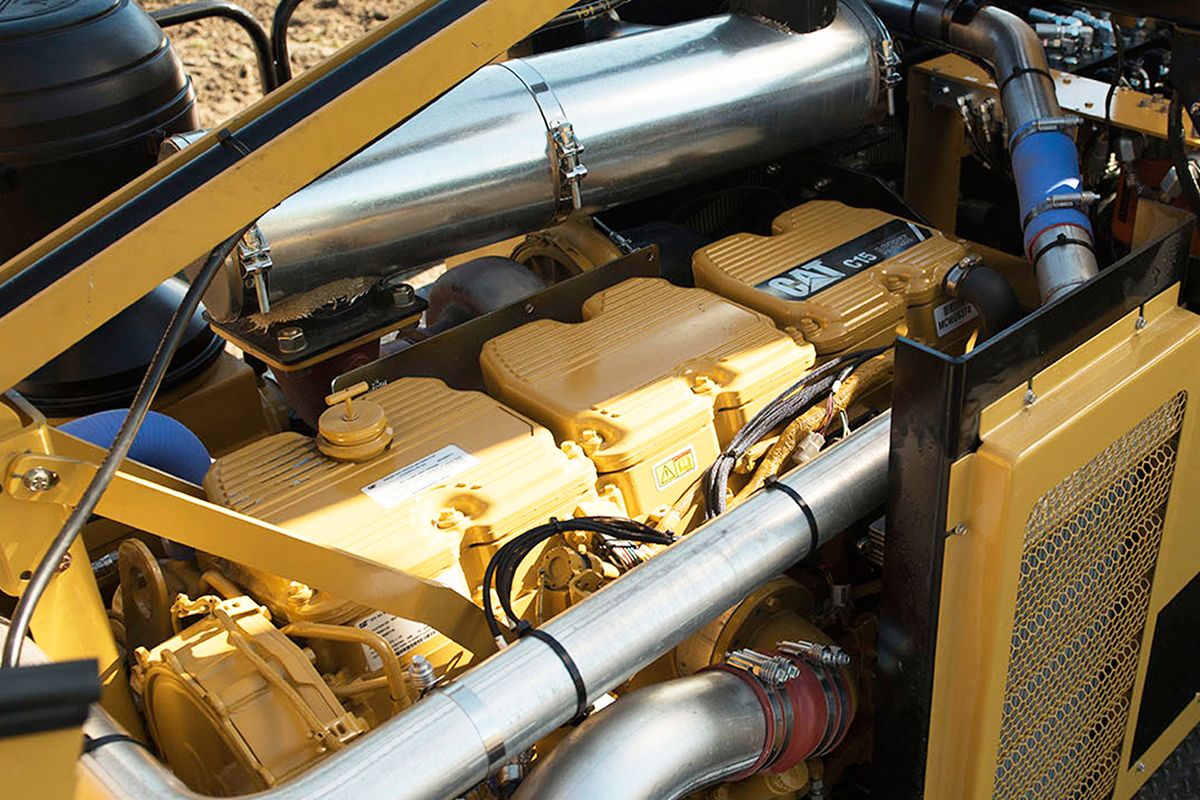

“It was absolutely no surprise to me that the C13D was going to power our 6880 pump trailer with rear PTO drive,” says Kyle Kirchhoff, a product manager at Puck. “We are driven by innovation and love to be on the cutting edge of what's next. The C13D brings an opportunity to increase our horsepower and keep the same vehicle size in that small and compact package.”

Setting The New standard

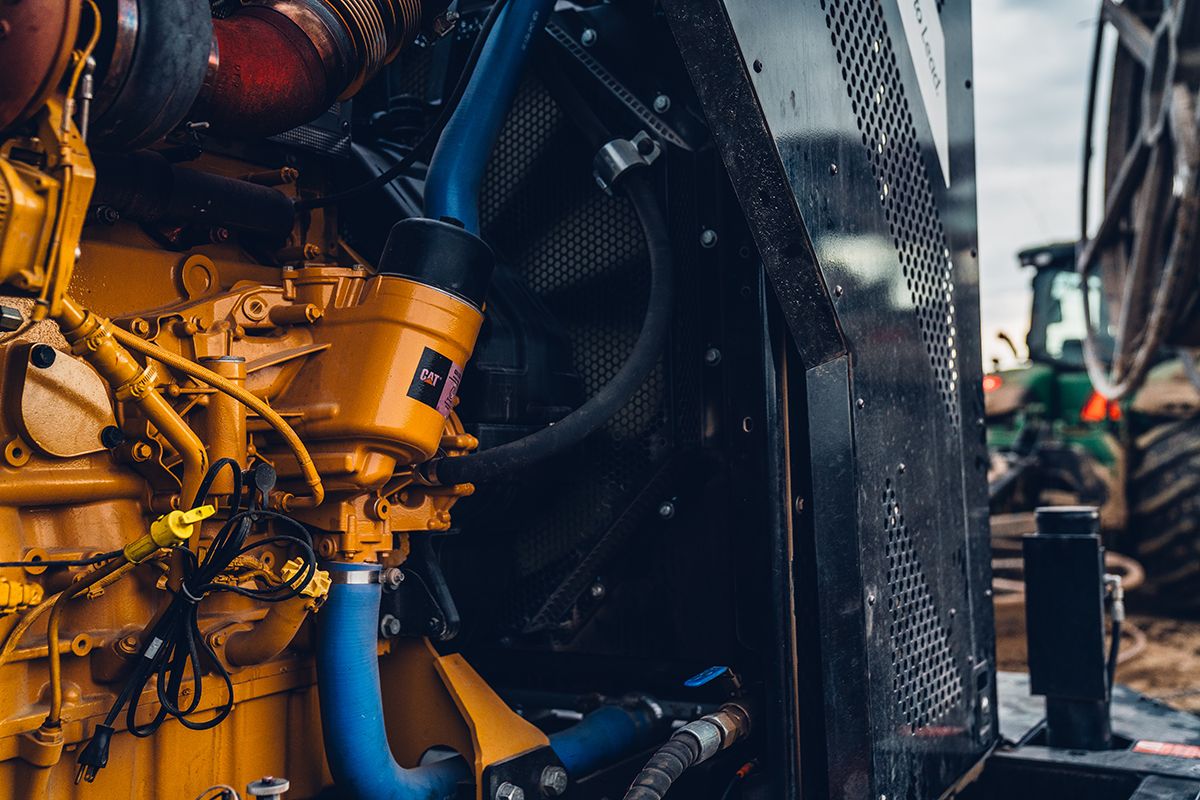

Puck has been operating the C13D on an 8,500-cow dairy farm near Manning, Iowa. The engine powers the 6880 pump trailer, which pulls millions of gallons of manure out of the lagoon and into three miles of pumps, eventually injecting the manure into the ground as fertilizer for the following year’s crops. Puck has been running the engine at 80% load, which allows them to pump more than 4,000 gallons per minute.

“More power means more manure moved,” explains Allen Chen, Caterpillar’s marketing manager for the C13D. “The C13D boasts about 20% more reliable power1 and low-speed torque compared to their current engine, the Cat C13B. More power means more pumping—thus, more productivity, and therefore, more money in their customers’ pockets.”

Moving gallons efficiently is essential in the manure business because the window of opportunity is so short. Puck’s spring season is only 30 days, and fall fertilizing is lucky to hit 90 days—and that’s the entire year’s worth of opportunity to gather revenue.

The extended service intervals on the C13D are also an important factor for Puck. After years of 100-hour service intervals, they’re experiencing 10 times that with the C13D—a “humongous difference for the customer,” according to Jeremy. “Being able to stretch to 1,000-hour service intervals is a direct savings for both us and them, since now we don’t even have to do an oil change in-season.”

The C13D also boasts three decibels of noise reduction,2 smooth cold-starting and a compact package that drops into existing C13B systems. That’s helpful for Puck, as the 13-liter is currently their most popular package.

“One of the biggest takeaways I want a customer to have when they see the C13D is that it's a simpler engine,” says Allen. “It's easy to work with. It's more accessible. It's more serviceable. All of that translates to something people want to work with.”

“Collaboration is the key to innovation.”

The C13D isn’t the only thing people want to work with, as the relationship between Puck and Ziegler is also highly important to each of them.

“The dealer support for our customers is huge,” says Kyle. “If these pumps go down for whatever reason, it's not just a small event; it's a big deal. The amount of revenue loss per minute, per hour, when you're pumping liquid manure adds up very quickly. So, having a dealer support network that can get you up and running quickly is very, very important.”

“Collaboration is the key to innovation,” Jeremy adds, “and it’s a two-way trust thing. The relationship with Caterpillar has been very easy. They’re our preferred partner in engines.”

“It’s not just supplying engines, as people might think,” says Leonard Pipho, sales engineer at Ziegler. “It’s parts. It’s service. It’s a partnership. I see a long-standing relationship with Puck; they’ve got a lot of really interesting stuff in the pipeline.”

Generations of expertise

After the increased flow rates they’ve seen with the C13D, Jeremy is exploring water-transfer systems and industrial firefighting applications. This engine will be a key player in the large water-movement projects on the horizon, which, like all of Puck’s ventures, will greatly benefit the town of Manning.

“It's probably been the most rewarding part of growing a business—seeing the impact that we've made back to the town,” Jeremy says. Allen agrees. “The fact that they rely on us to give them the power that they need to maintain this farm…it's very rewarding. It's very impactful to see the C13D in action, moving the earth and doing value-added work in this world.”

1More power and torque based on product testing of C13B and C13D in lab development and testing conditions. Power & Torque measured as outputs via dynamometer testing and verified by mathematical calculations. Test conducted by Caterpillar at Technical Center L in 2024.

23 dB noise reduction based on product testing of C13B and C13D in lab development and testing conditions. dB “noise” measured as sound pressure and verified via a set number of microphones placed around a running engine within a semi-anechoic chamber. C13B tests were conducted by Caterpillar at Technical Center L in 2020, and C13D tests were conducted at the same location in December of 2023, with the differences being mathematically calculated in 2023.