A ‘BEST IN BASIN’ COMMITMENT

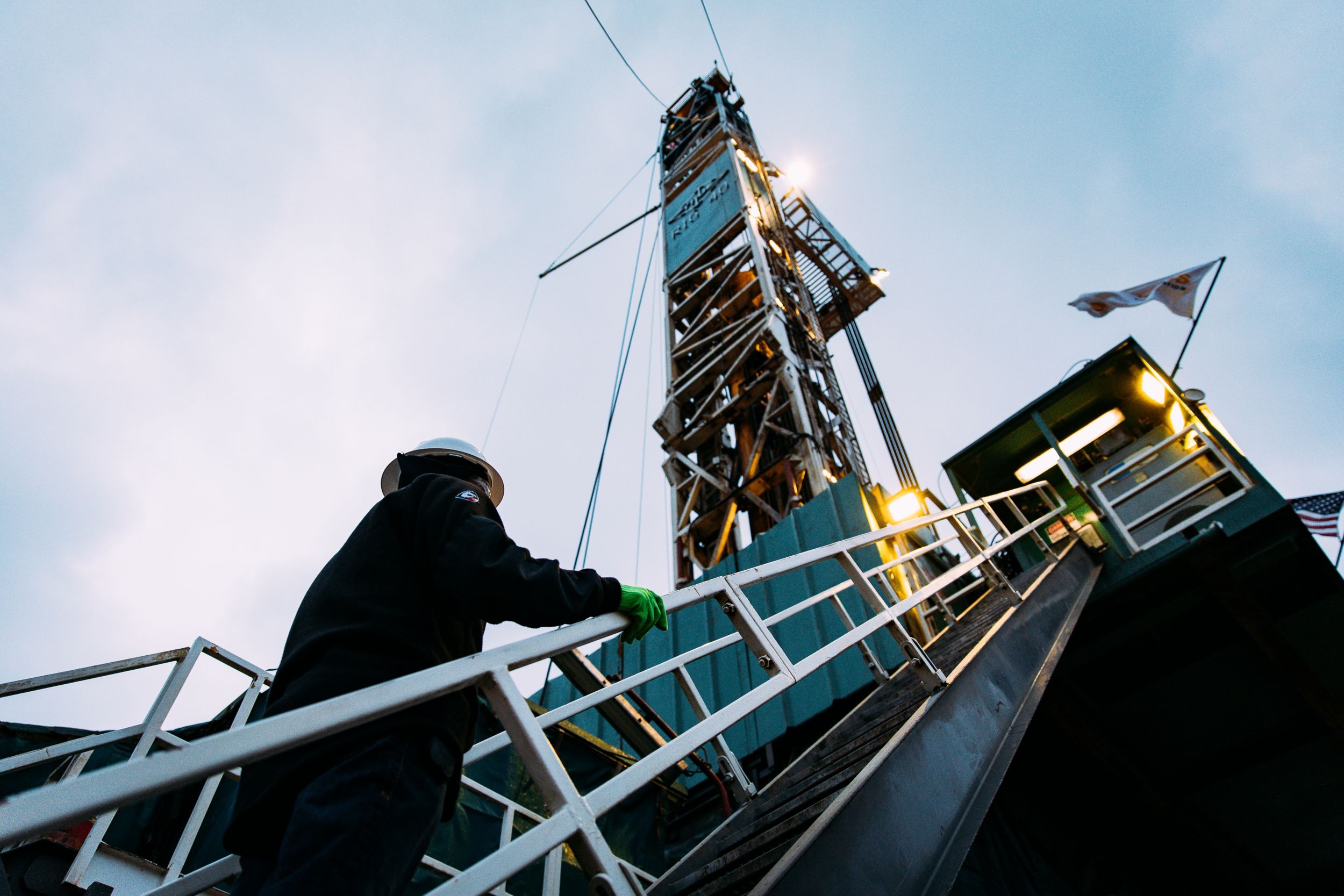

Enerplus, a leading E&P operator focused on the responsible development of high-quality crude oil and natural gas assets, is an innovator that challenges the status quo to embrace new approaches. Enerplus takes pride in being an early adopter of technologies that helps lower greenhouse gas (GHG) emissions in their operations while also cost effectively maximizing production, which ultimately supports their goal of attaining a 30% reduction in emissions intensity by 2030. Their objective to be ‘best in basin’ relies on adhering to three core principles: using the safest and best technology; operating the most productive wells; and having the strongest industry relationships.

Those industry relationships are key on a project. It takes more than teamwork – it takes common goals and a shared philosophy of embracing technology that is new and next, especially when striving to meet sustainability goals.

DOING THE HARD WORK - TOGETHER

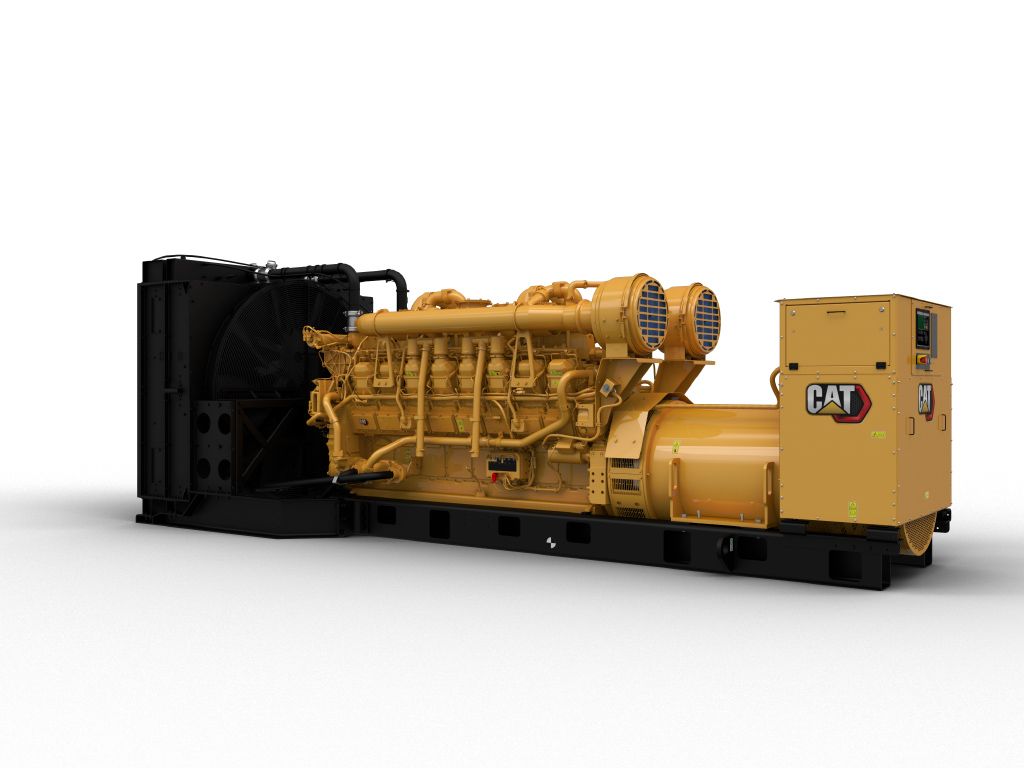

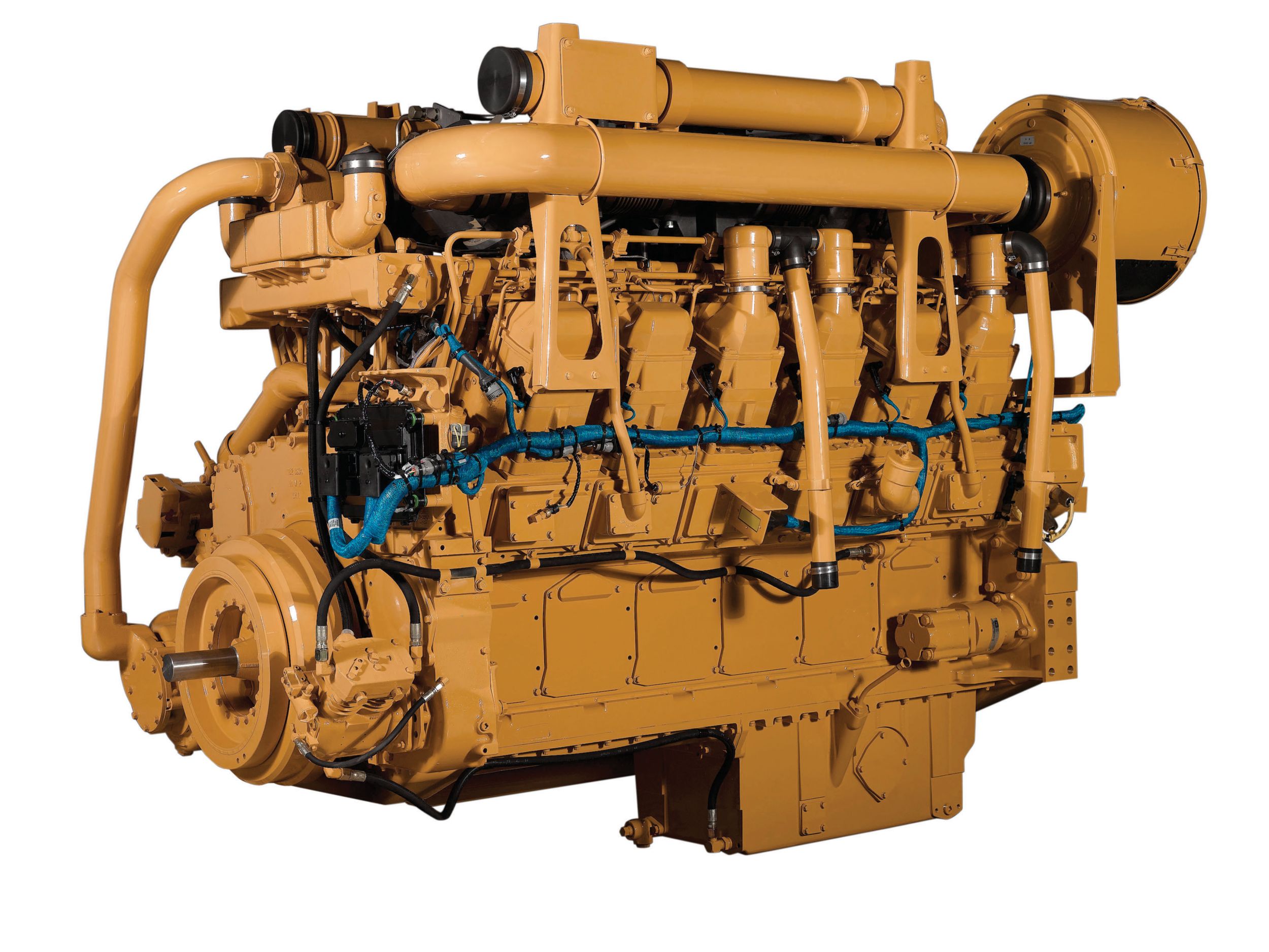

A theme that has underpinned True Drilling over its 75 years is its focus on being best in class; not the largest. The company takes a long-term view and prioritizes relationships and teamwork. True Drilling has used Cat® machinery from day one. Today, their equipment includes C32 and C3512 engines. Their current fleet of gensets operate in the harsh extremes of the Rockies on a 24/7 continuous duty.

“Cat equipment is so dependable we can essentially set it and forget it,” commented Bill DeGraeve, True Drilling’s director of drilling.

When Enerplus, a long-standing customer, approached True Drilling to help identify a way to reduce their emissions profile and operating costs, the driller engaged Wyoming Machinery Company; a Cat dealer they’ve trusted for more than 25 years.

Wyoming Machinery Company has helped pioneer the new Cat Hybrid Energy Storage Solution, having installed a majority of the first solutions in the field. They’ve made significant investments in engineering and development teams to support a continuous improvement approach that keeps pace with the industry’s changes. Wyoming Machinery Company quickly recognized the Cat Hybrid Energy Storage Solution would perfectly meet Enerplus’ demands to lower emissions, maximize uptime, limit operating expenses and optimize existing equipment.

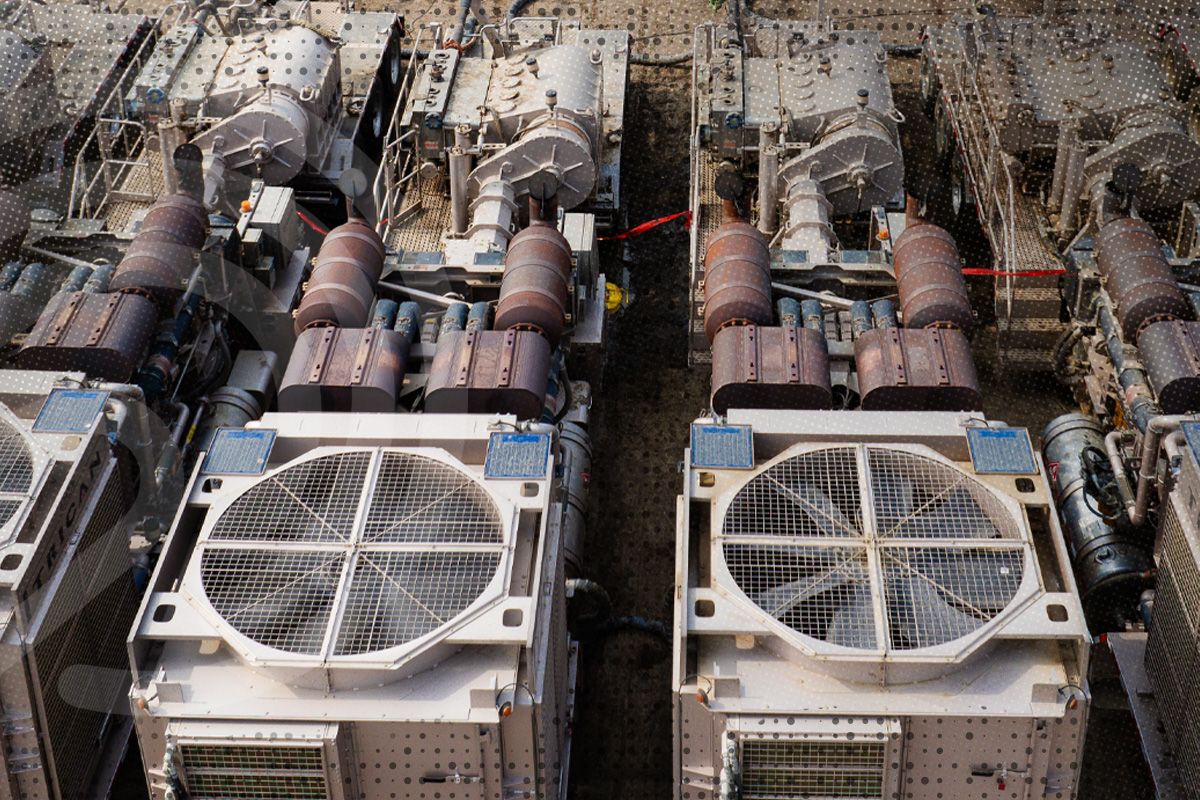

The Hybrid Energy Storage Solution is a custom-designed battery storage system that can be combined with with natural gas, diesel or blended fuel (DGB) engines and stores excess power from the job site so that it can be discharged as needed. When combined with a natural gas genset, the transient response is even faster than in traditional diesel-only rigs. The technology is an important advancement for the drilling industry as it gives drillers maximum fuel flexibility while ensuring critical transient response capability. This eliminates the need for a redundant engine (even at high altitudes), and reduces runtime hours and emissions.

The three companies collaborated to install the leading-edge technology and ensure True Drilling and Enerplus reaped all its benefits. Caterpillar engineers also joined the teams on-site to share learnings about the new technology and fine-tune the Hybrid Energy Storage Solution for the project’s needs.

The customizable solution provided to True Drilling equipped their rig with a combination of key technological shifts to reduce greenhouse gas (GHG), nitrogen oxide (NOx) and particulate matter emissions*:

- Cat Hybrid Energy Storage Solution

- Cat DGB engines operating with compressed natural gas (CNG), equipped with

- Cat Smart Engine Management System (Smart EMS)

DEPENDABLE INNOVATION AND SUSTAINABILITY IMPACT

The diligent efforts of Enerplus, True Drilling, Wyoming Machinery Company and Caterpillar paid off as the technology reduced diesel use and emissions. The companies solidified their trailblazer reputations with the successful installation and early adoption of the Cat Hybrid Energy Storage Solution in the field.

With the Hybrid Energy Storage Solution, True Drilling went from four gensets to three and reduced daily engine hours by 1/3, with a corresponding reduction in diesel consumption and emissions. The technology provides Enerplus and True Drilling the most efficient platform to redeploy the produced natural gas. It maintains their uptime which is important, as downtime costs thousands of dollars per hour. With unwavering support through a collaboration of Cat dealers, Enerplus and True Drilling were able to maintain optimal system performance as the rig moved to the next site. This level of mobility, an important consideration when selecting the solution, proved advantageous for both True Drilling and Enerplus.

“The Hybrid Energy Storage Solution helps fulfill our goals of improving capital efficiency, reducing emissions, driving the evolution of technology and effectively managing the resource through the reduction in flaring.” said Terry Eichinger, vice president, drilling, completions and operations support for Enerplus.

The Hybrid Energy Storage Solution reduced True Drilling’s startup times, as they simply flip a switch and the system is energized. Additionally, they observed that the hybrid technology can reduce costs significantly by curbing peak power load per day.

“With the Hybrid Energy Storage Solution, we can give operators consistent drilling performance time, drill farther faster and increase safety,” added DeGraeve.

The oil and gas industry is more dynamic than ever. As companies seek to advance sustainability while improving costs and ensuring performance, new ways of thinking – and operating – will be necessary. Collaborative relationships and field-proven technological advances will service all oil and gas companies well as they face the future.

“As E&P’s and drillers strive to lower their emissions and maintain the performance they’re accustomed to, the Hybrid Energy Storage Solution is a gamechanger,” commented Lukas Munsell, director of power systems at Wyoming Machinery Company.