Weights - Approximate

| Nominal Rated Payload | 213 ton (US) 193 t |

| Rated Gross Machine Weight | 715,000 lb 324,318 kg |

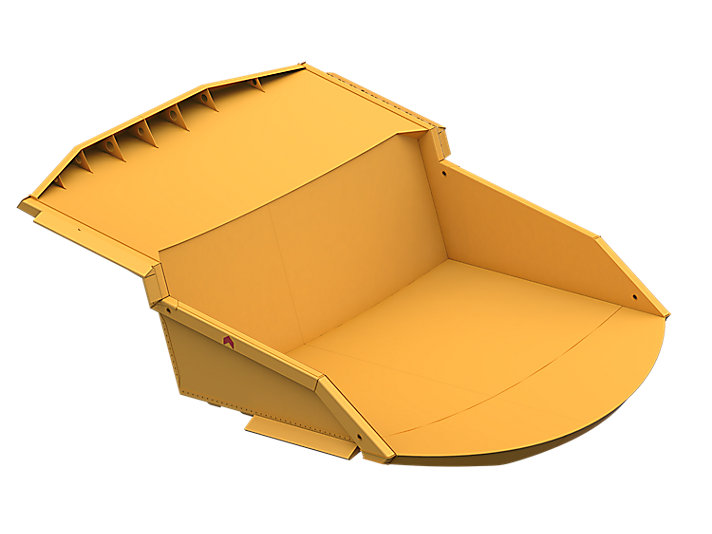

| Body Weight | 60,406 lb 27,400 kg |

| Note (1) | Consult your tire manufacturer for maximum tire load Consult your tire manufacturer for maximum tire load |

| Note (2) | Chassis weight with full fuel and fluids, standard and mandatory attachments, hoist, body mounting group, rims, and tires. Chassis weight with full fuel and fluids, standard and mandatory attachments, hoist, body mounting group, rims, and tires. |