INCREASED PAYLOADAdditional counterweight improves stability without reducing ground clearance or departure angle to maximize performance.

LONG LIFE SAND AND GRAVEL BUCKETSPerformance Series Buckets deliver higher fill factors and better material retention for significant productivity and fuel efficiency improvements. The buckets feature a long floor, open throat, curved side bars and additional serviceable wear plates including corner guards.

PROTECT YOUR POWER TRAINIncrease your fording depths with optional elevated breathers. Remote mounted high on the machine for the front and rear axles and hydrostatic gear box. Allows settling pond clean out without contamination.

The Cat® C7.1 engine provides cleaner, quieter operation while delivering superior performance and durability through a high torque, low speed design. Caterpillar's exclusive Intelligent Power Management system monitors operator input and power availability to keep the machine working at peak efficiency and provide the operator with greater customization to suit their application.

A choice of Power Modes allows you to choose between maximum fuel efficiency or boosted power along with hydraulic speed.

STANDARD POWER MODE- Saves fuel and reduces cab sound levels

- Biggest gains are seen during load and carry, snow removal and roading applications

PERFORMANCE POWER MODE - Enabled at the push of a button (HP+), boosts engine power by up to 10% and engine speed by over 12%

- Increases hydraulic cycle times and productivity

Lock up and go with fully locking front differential axle that can be engaged on the move at full torque. Maximize your traction with optional Limited Slip Differential on the rear axle to keep you climbing.

A spacious, quiet and comfortable operator environment helps keep you relaxed and productive throughout the day. Experience superior all around visibility with single piece front windshield, redesigned linkage and clean hydraulic lines routing. Seat-mounted controls featuring low effort joystick for lift and tilt functions along with integrated Forward/Neutral/Reverse switch, differential lock trigger and optional third and fourth auxiliary functions.

- Automatic climate control with heated rear glass and external mirrors

- Information at a glance with large primary LCD display

- Heated and cooled seat option

- Optional Ride Control

- Exclusive electro-hydraulic cylinder snubbing

- An extra eye on the job site with optional integrated rear object detection and optional* rearview camera

*Standard in Europe.

The M Series Aggregate Handler will remember you and your personal settings with unique operator codes to make this machine truly yours and keep it secure.

Work as one with your machine by customizing your controls.

- Select your Power Train Mode

- Reduce tire wear using Rimpull

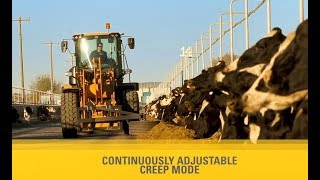

- Fine tune ground speed with Creeper Control

- Adjustable Electo-Hydraulic Controls

- Set Directional Shift Response based on job application

Get up and running quickly with ground level, daily service access and optional engine compartment lighting. Three large service doors can be opened and closed in any order to give full access to filters and service points. Extended service intervals on hydraulic and power train filters reduce service time and maximize uptime. Additional service features include:

- Product Link™ PRO standard with optional subscription to VisionLink®.

- Maintenance reminders through secondary display at scheduled intervals.

- Fit for Life Diesel Particulate Filter that is designed to exceed the engine overhaul life.

- Quick fuel filter service with Caterpillar's exclusive electric fuel priming pump.

- Jump start studs as standard equipment.

- Extended cleanouts with single plane cooling system and wide spaced 6 fans per inch coolers as standard.

- Integrated Autolube (optional) with adjustable greasing frequency.

With renowned Cat dealer support, rely on your Cat dealer to help you every step of the way with new or used machine sales, rental or rebuild options to meet your business needs.

Maximize your machine uptime with unsurpassed worldwide parts availability, trained technicians and customer support agreements.

Let us earn your business. Experience an M Series Small Wheel Loader and join the Caterpillar family.