A Legendary Legacy that Leads

- Founded in 1925, Caterpillar established the standard for tractors and construction equipment from the outset. Over the years, the company’s leaders have gained a great deal of knowledge about what works and what doesn’t. Caterpillar has grown alongside its customers, developing new products for hardworking individuals who want to push the limits. With that history comes innovation, change, creation, and learning. Caterpillar has partnerships across multiple industries and companies, continually developing and refining its understanding of how equipment should operate. Our commitment to designing and building the world’s best equipment is evident in every single product.

Machine Setup Simplification

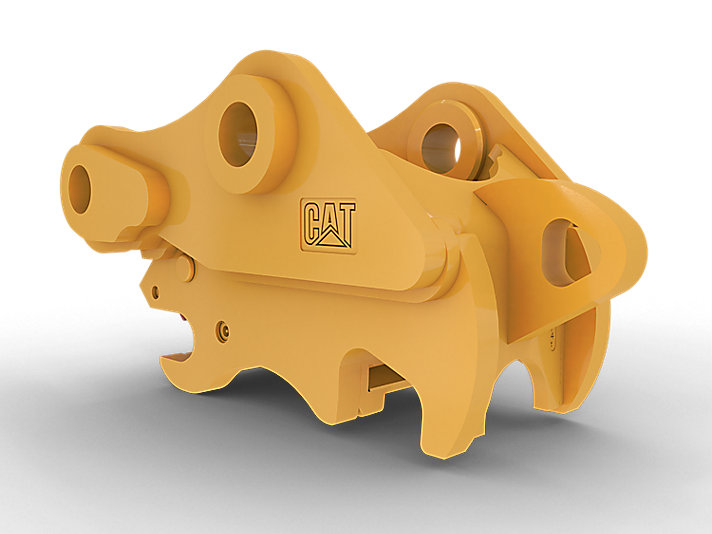

- At the touch of fingertips and navigating user-friendly icons, the latest operator oriented User Interface (UI) maximizes uptime and gets crews to work without delay. From re-ordering work tool lists to creating new work tool combinations as needed, operators can quickly set up machines and easily access information.

- The interface allows operators to maintain accuracy and makes the most of every second of their shift. Adding the ability to input couplers and attachments into the system makes setting up work tool combinations highly efficient by significantly reducing calibration time. It also eliminates the need to measure up again when changing Cat© work tool attachments and makes it manageable for a single person to check and adjust for bucket wear.

Cat Grade 3D Ready

- The Cat Grade 3D Ready option includes all the hardware required for the Grade with 3D system, installed and tested from the factory. This option provides an easier upgrade path for customers who want to add Grade with 3D after their initial purchase. To activate, contact your Cat Dealer to purchase the required 3D software licenses. Licenses can be installed remotely or manually loaded onto the machine.

Cat Payload and Advanced Payload

- Cat Payload provides operators with on-the-go weighing to help them hit load targets and avoid overloading, underloading, or misloading materials. Advanced Payload is a system upgrade that offers expanded features and capabilities, including custom tags, daily totals, and electronic ticketing. Combine Payload with VisionLink® Productivity* to analyze jobsites and individual assets for remote management of production targets and key metrics.

* VisionLink® subscription required.

Availability may vary by region, consult your Cat® Dealer for more details.

Build Number: 06D

- The latest operator oriented User Interface (UI) has been designed to maximize uptime by allowing operators to easily reorder work tool lists and quickly create new work tool combinations. It also eliminates the need to measure up again when changing Cat® work tool attachments and makes it manageable for a single person to check and adjust for bucket wear.

- Cat® Lift Assist helps avoid machine tipping. With visual and auditory alerts, operators will know if their load is within the excavator’s safe working range limits.

- Cat® 2D E-Fence restricts the front linkage from moving beyond operator-defined preset boundaries for the ceiling, floor, wall, swing, and cab. It helps operators avoid jobsite hazards such as traffic, keeps personnel safe, and helps you save on costly repairs, equipment downtime, and potential jobsite fines.

- Cat® Detect - People Detection for excavators is an intelligent vision camera system that can alert an operator when someone enters a machine’s hazard zone.*

- Cat® Grade with Assist helps operators stay on grade simply and effortlessly with semi-autonomous digging. It automates boom, stick, and bucket movements to deliver more accurate cuts with less effort.

- Cat® Grade with 2D for excavators is an indicate system that helps operators reach grade faster.* Select your target depth and slope and watch the Grade with 2D system use on-board processors and sensors to provide real-time guidance on the distance to grade.

- Cat® Grade with 3D for excavators helps operators grade more quickly, accurately, and efficiently, improving productivity.* It incorporates GNSS technology and RTK positioning guidance to streamline the grading process for complex designs commonly encountered on large infrastructure and commercial projects. This system allows operators to work confidently, eliminating guesswork while cutting and filling to precise specifications.

- The Cat® Grade 3D Ready option includes all the hardware required for the Grade with 3D system, installed and tested from the factory. Activation requires the purchase of additional 3D software licenses, contact your Cat Dealer for details.

- Upgrade to our dual antenna GNSS for maximum grading efficiency. The system lets you create and edit designs on the touchscreen monitor while you’re on the job, or you can have the plan design sent to the excavator to make your work easier. Plus, you get added benefits of avoidance zones, cut and fill mapping, lane guidance, and augmented reality along with advanced positioning capability.

- All Cat Grade systems are compatible with radios and base stations from Trimble, Topcon, and Leica. Already invested in a grade infrastructure? You can install grade systems from Trimble, Topcon, and Leica onto the machine.

- Cat® Payload provides operators with on-the-go weighing to help them hit load targets and avoid overloading, underloading, or misloading materials. Advanced Payload is a system upgrade that offers expanded features and capabilities, including custom tags, daily totals, and electronic ticketing. Combine Payload with VisionLink® Productivity** to analyze jobsites and individual assets for remote management of production targets and key metrics.

- Cat® Operator Coaching allows operators of all experience levels to take their efficiency and productivity to the next level. With tips and data at their fingertips, operators can track and improve their productivity through everyday work on the job site. Gain data-based insights towards operators and operations when you pair Operator Coaching with VisionLink® Productivity.** There are two coaching tip categories –

- Operational Efficiency Tips: Help operators stay at the top of their game by identifying areas to increase skill and efficiency, such as digging technique and idle times.

- Machine Health Tips: Some actions are inefficient and cause unnecessary wear and tear on the machine and its components. Following Machine Health Tips can help extend the life of the machine, improve digging technique, and reduce fuel waste.

*The system may not detect personnel in certain circumstances, such as fast swing speeds, people lying down or crouching, or when cameras are impaired by low light conditions (dusk, dawn, overcast), inclement weather (snow, rain, fog), or other similar conditions. For limitations of use, refer to the operation and maintenance manual.

** VisionLink® subscription required.

NOTE: Cat® Payload for excavators is not legal for trade. Availability may vary by region, consult your Cat Dealer for more details.

- The 350 uses a keyless push-button engine start. This adds security for the machine by using Operator ID codes to limit and track machine access. Codes can be entered manually via an optional Bluetooth key fob.

- Most machine settings can be controlled through the high-resolution touchscreen monitor. It offers several languages and is easy to reach from the seat – no twisting or turning.

- A second 254 mm (10 in) monitor is available for the Cat® Grade and Cat® Grade with 3D.

- Operating can be made easier with the touch of a joystick button. The joystick function can be customized through the monitor. The joystick pattern and response can be set to match operator preference. * All preferences are saved with the Operator ID and restored at login.

- Make moving the excavator much easier with Cat® Stick Steer. Push a button and use one hand to travel and turn instead of both hands or feet on levers or pedals.

- You can also add an auxiliary relay to power on or turn off a CB radio, beacon light, or other attachment so you don’t have to take your hands off the joysticks.

- Program up to four depth and slope offsets so you can easily get to grade without a grade checker – saving time and enhancing safety on the jobsite.

- Operator coaching is an in-cab system that recognizes specific opportunities for operators to be more productive and prevent unnecessary machine wear and tear.

- Not sure how a function works or how to maintain the excavator? Always have the operator’s manual at your fingertips on the touchscreen monitor.

- Use the in-monitor QR code to learn about machine and technology features through a full suite of “how-to” videos.

Not all features are available in all regions. Please check with your local Cat® dealer for specific offering availability in your area.