When you buy Cat® equipment, you get more than the machine. You’re also getting the support of a best-in-class dealer network backed by a range of flexible solutions, technology, tools, and more.

When you work with your local Cat dealer, you'll be supported by one of the industry's most extensive, knowledgeable dealer networks. Comprised of 160 independent dealers, the Cat Dealer Network serves 197 countries with thousands of branches around the globe.

It’s more uptime, cost-saving service and repair options, quality parts, and precision components. It’s all about support built around your success.

Ask your Cat dealer today about the many services that help you do your work your way.

- The importance of buying genuine Cat parts.

- Designed by Caterpillar engineers to the exact specs of your Cat equipment.

- Rigorously tested to ensure maximum performance.

- Covered by a 12-month warranty.

- Cat Inspect – Work made easy.

- Record real-time inspection data.

- Simplify inspections and reporting.

- Easy-to-read results all in one place.

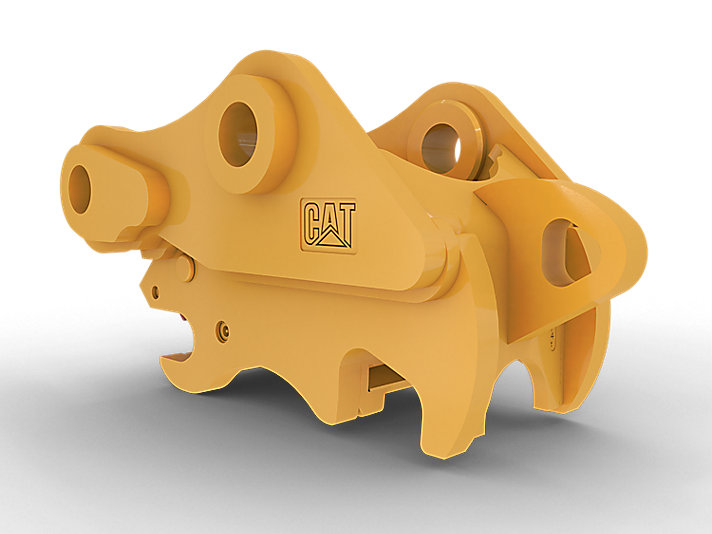

- Cat Ground Engaging Tools (GET) – Longer wear. More work.

- GET for every machine and application.

- Tools to extend life and track GET lifecycles.

- Bucket rebuild options for optimal performance.

- Cat Hydraulic Components – Durability quality you can work with.

- Flexible options – New, reman, exchange, rebuild or repair.

- Expert diagnostics, testing, and contamination control.

- Buy in-store, online, or on your mobile device.

- Cat Hose Service – Fast, safe—to get you back to work.

- Hoses and couplings for most makes and models.

- OEM database ensures an exact fit.

- Industry-best tooling, training, and assembly standards.

- Cat Certified Rebuild – An investment that works. Again, and again.

- Better-than-when-new performance at a fraction of the cost.

- Performance, safety, and technology upgrades and enhancements.

- Full warranty coverage, Customer Value Agreement, and special financing.

- Cat Remote Services – Work done in a flash.

- Cut downtime for updates and service.

- Install the latest machine software remotely.

- Troubleshoot issues before a technician arrives.

24/7 Expert Support

Get industry-leading support for any question or problem you have 24 hours a day, 7 days a week, 365 days a year.

CALL US

We’re available 24/7 at

Toll Free:

1-888-228-1460

Direct:

1-513-830-1806

SMS:

+13098656129

Learn more at

https://parts.cat.com/

- The Cat® C13 engine meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

- The 352 UHD emits up to 31% less CO2 than the 345C.*

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels*** up to: 20% biodiesel FAME (fatty acid methyl ester)** or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Auto engine speed control reduces unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- Cat Scheduled Oil Sampling (S•O•S℠) Services helps reveal excessive wear, contaminated fluids or other “unseen” issues that can shorten component life. In many cases, you can extend oil and coolant change intervals by using fluid monitoring. Consult your Cat dealer or the machine's operation and maintenance manual for more information.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- Cat Grade technologies combine advanced guidance with optional automated machine control helping you reach grading targets while reducing fuel burn and greenhouse gas emissions by improving efficiency, job site productivity, and accuracy.

- Cat® Payload for excavators provides on-the-go material weighing which helps reduce fuel burn by improving loading efficiency, job site productivity, and eliminating trips to the scale.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

*All comparisons to 345C. Productivity, fuel, and CO2 emissions vary by application. CO2 emissions calculations based on a reference work cycle using 2.2 U.S. gallons per hour of #2 U.S. diesel fuel based. Applies IPCC2006 methodology using U.S. EPA Emissions Hub emission factors. Includes DEF (diesel exhaust fluid) related CO2. Fuel measurements are at 15°C. Estimated average fuel consumption improvements are based on tests or Product Link™

data where available. Productivity improvements are based on test data.

**Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).

***Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.