If you already have an existing account with another Cat App, you can use the same account to sign in here.

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

What to Know About Buying Rebuilt (or Refurbished) Heavy Equipment

Machine owners looking to save money often choose to buy heavy equipment that has been rebuilt (often referred to as refurbished). Should you? Here’s what to expect from a rebuilt machine versus buying new.

Estimated read time: 3-4 minutes

Machine owners looking to save money often choose to buy heavy equipment that has been rebuilt (often referred to as refurbished). Should you? Here’s what to expect from a rebuilt machine versus buying new.

HEAVY EQUIPMENT REFURBISHING VS. REBUILDING: WHAT’S THE DIFFERENCE?

Is a machine refurbishment the same as a machine rebuild? The two words often get used interchangeably. Both mean essentially the same thing: returning equipment at the end of its life expectancy to like new condition.

At Caterpillar, we use the term “rebuild” because that’s what our process entails. We take advantage of the extra life built into every Cat® product to rebuild equipment from the ground up. As a result, it performs like it did when it was new. In some cases, it performs better than new thanks to optional upgrades and enhancements.

The Cat Certified Rebuild Program includes machine, commercial engine, power train, hydraulic system and machine component rebuilds. Cat Certified Rebuild machines get a new product identification number (PIN) and a like new standard warranty on all replacement parts.

WHAT’S INCLUDED IN HEAVY EQUIPMENT REFURBISHING OR REBUILDING?

It depends. Not all construction equipment manufacturers follow the same steps. Nor do they hold a machine rebuild to the same standards. If you’re considering rebuilt or refurbished heavy equipment, make sure to ask about the process. That way, you can compare options to make the best decision.

For example, here’s a look at what every Cat Certified Rebuild machine must undergo:

Fluid analysis, visual inspections and a review of the machine’s service history

Disassembly and inspection of parts and components

Reconditioning work not included in a typical overhaul

Engineering updates introduced after the original manufacture date

Reassembly and automatic replacement of parts that don’t meet strict reusability standards

Comprehensive powertrain and performance testing

Repainting, new model identity graphics and a Cat Certified Rebuild decal

There’s a lot more involved in the Cat Certified Rebuild Program. Take a look at this article and brochure for additional details. You can also reach out to your local Cat dealer below.

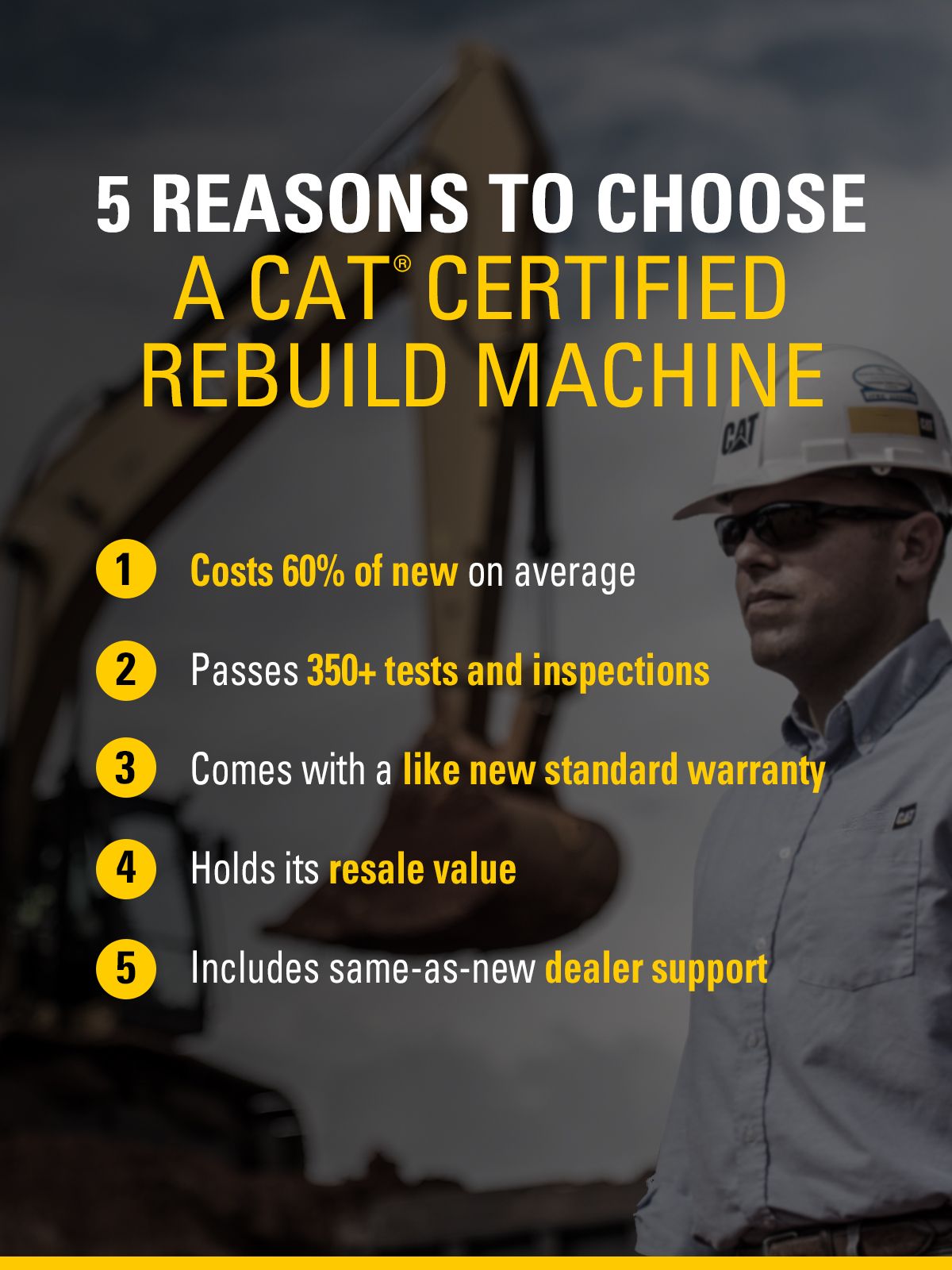

WHY CHOOSE A REBUILT MACHINE VS. A NEW ONE?

There are pros and cons to both options. The decision depends on multiple factors — including your budget, timeline and business goals. Many construction equipment owners choose rebuilt or refurbished heavy equipment for these reasons:

Cost: Machine rebuilds are usually priced at a fraction of the cost of buying new equipment. Every Cat machine is built for two or even three lives.

Timeframe: If supply chain issues are a challenge, it may be quicker to acquire a rebuilt machine rather than a new one.

Warranty: Coverage varies by manufacturer, but it can be quite comprehensive. Some companies also let you add extended protection to a rebuilt machine for peace of mind.

Resale value: Machines that are rebuilt to a strict set of standards tend to hold their resale value. Adding an ownership and maintenance plan — like a Customer Value Agreement — can help increase resale value.

Parts availability: With a rebuild, or refurbishment, it’s often easier to access spare parts and aftermarket kits to expand machine capabilities.

Upgrades: Some rebuilt machines include features and technologies that are upgraded to current standards. That’s a way to enhance productivity and efficiency without making an investment in new equipment.

Waste reduction: Heavy equipment rebuilding or refurbishing reuses some components. That helps extend the life of materials.

Support services: Depending on the rebuild supplier you choose, you may have access to like new support for your rebuilt equipment. Cat dealers offer maintenance plans, repair options, financing and more.

Want to take a deeper dive into the benefits of a machine rebuild vs. new equipment? Check out this comparison to review when you should consider repairing, rebuilding or replacing.

READY TO TAKE THE NEXT STEP?

Still debating whether a rebuilt machine or new equipment is your best option? Want to know more about the Cat Certified Rebuild Program? Get in touch with your local Cat dealer for advice, answers and rebuild expertise.

Related Stories

-

How to Assess the Health of Your Safety Management System

Hear from the General Manager of Caterpillar Safety Services about the steps you can take to ensure a healthy safety management system for your operation.

Learn More -

Drilling Into The Advantages Of Cat® Reman Engines

To save time and money, Keystone Drill Services uses Cat® Reman for compressor rebuilds.

GET THE STORY -

Exploring Electrification in the Oilfield

Electric fleets and natural gas-powered solutions are transforming wellsite services. As mobile power generation technology evolves, the oil and gas industry is exploring how to erect different types of microgrids that can be customized to their unique operational needs.

Learn More -

The Future of Gas Compression: LNG Offers Multiple Opportunities for Operators

As gas compression operators look to the future, liquefied natural gas (LNG) appears to have a bright outlook. Multiple major oil and gas companies have stated plans to increase investment in the LNG landscape – as LNG tends to emit less carbon dioxide (CO2) and particulate matter than conventional fuels – and it has a strong growth trajectory projected for the future.

Learn More