Weights - Approximate

| Nominal Rated Payload | 160 ton (US) 145 t |

| Rated Gross Machine Weight | 550000 lb 249476 kg |

| Chassis Weight | 184791 lb 83820 kg |

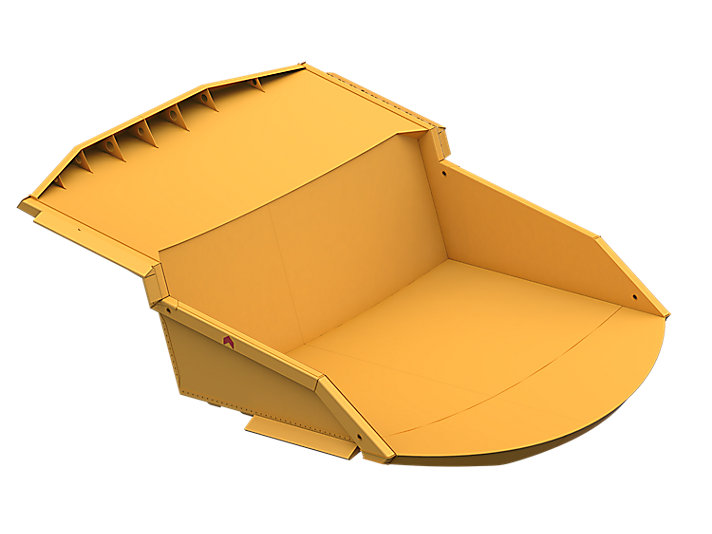

| Body Weight Range | HP (144 cyd): 20 917 kg (46,114 lb); HP Coal (192 cyd): 21 948 kg (48,387 lb); X body: 25 091 kg (55,316 lb); Dual Slope: 23 538 kg (51,892 lb); MSD II: 21 188 kg (46,712 lb); Gateless Coal (183 cyd): 24 019 kg (52,952 lb); Gateless Coal (217 cyd): 25 066 kg (55,261 lb); HP (144 cyd): 20 917 kg (46,114 lb); HP Coal (192 cyd): 21 948 kg (48,387 lb); X body: 25 091 kg (55,316 lb); Dual Slope: 23 538 kg (51,892 lb); MSD II: 21 188 kg (46,712 lb); Gateless Coal (183 cyd): 24 019 kg (52,952 lb); Gateless Coal (217 cyd): 25 066 kg (55,261 lb); |