LOWERING YOUR FUEL COSTS

- We've designed our trucks to use less fuel, which reduces engine emissions and carbon footprint, and there is zero fuel burn during retarding.

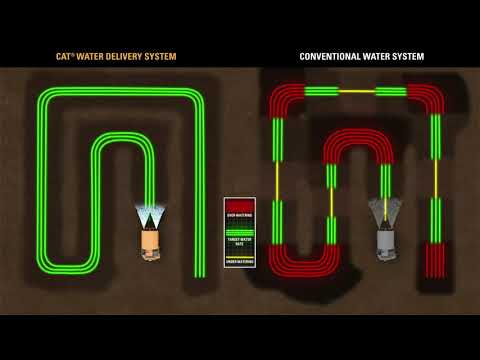

WATER DELIVERY SYSTEM:

- The water cannon operates at idle, which reduces fuel consumption during cannon operation by up to 50%.

*Results shown from Cat WDS cannon output. Testing was conducted at the Caterpillar Tucson Proving Ground with data captured from a production study. Results may vary.

CONNECT WITH CAT® MINESTAR™

- Cat MineStar for water uses cloud-based connectivity through cellular and WiFi connection to collect and manage data at any job site.

- We offer two levels of connectivity (Basic & Premium*) to meet any customer need using Cat MineStar.

- Water Solutions data can help ensure customers are meeting regulatory requirements.

- View maps and dashboards of your operation to see how much your trucks are watering, where they are located, how much fuel they are using, and more.

BASIC CONNECTIVITY: EQUIPMENT TRACKING

“I need to know where my truck is located and when it’s watering.”

Basic Connectivity* automates fundamental data collection, eliminating paper recording by the operator.

- Near-real-time and historical reporting.

- Truck location and utilization data: routes, starts and stops.

- Fuel and water level.

- Whether or not the truck is spraying water.

- Water Delivery System utilization (auto vs. manual mode).

*Based on equipment connectivity via WiFi or cellular data. Basic Connectivity Package comes standard with a 6-month complimentary service-based offering.

PREMIUM CONNECTIVITY: EQUIPMENT TRACKING + PRODUCTION RECORDING

“I need to understand fuel utilization, water cycle duration, and how much water the truck is using.”

Premium Connectivity* offers a comprehensive reporting package with data and detailed reports o help mine managers and operators improve watering techniques and efficiency.

- Water usage by truck/fill station.

- Volume of water output over time and area covered.

- Water distribution rate, water delivery system

- setting by location, truck, and conditions.

- Activity breakdown including time and distance.

- (watering, not watering, stopped, etc.)

- View and export at least 6 weeks of historical data.

*Based on equipment connectivity via WiFi or cellular data.