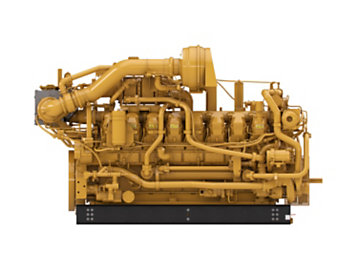

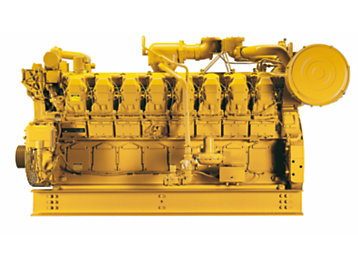

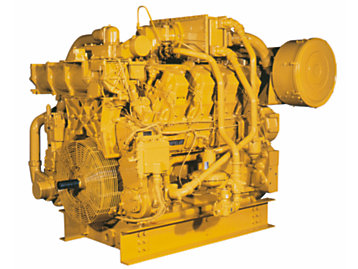

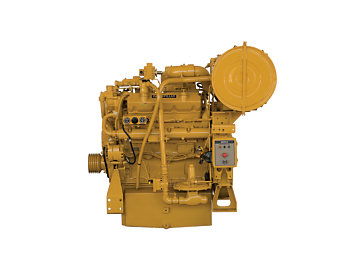

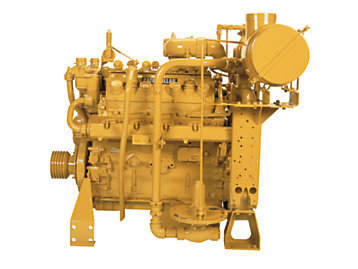

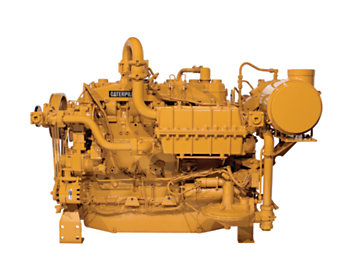

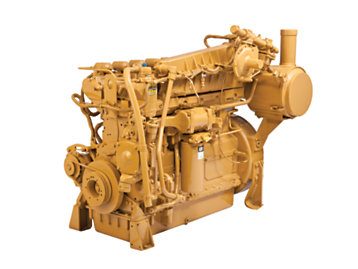

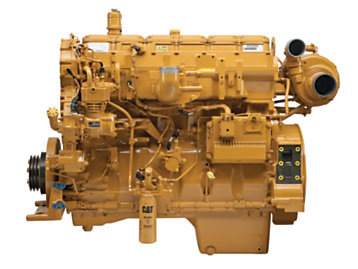

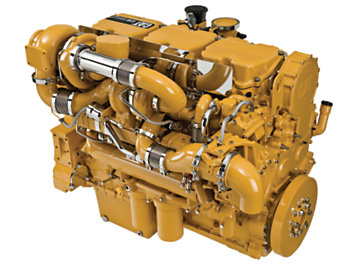

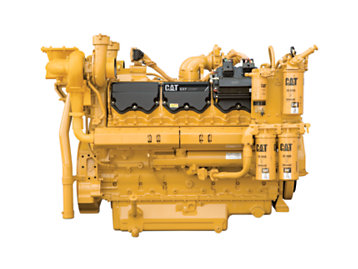

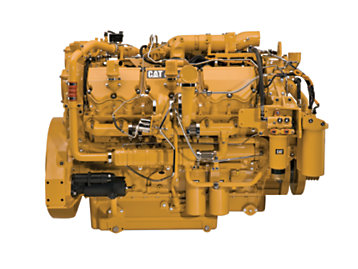

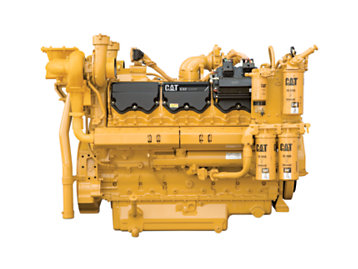

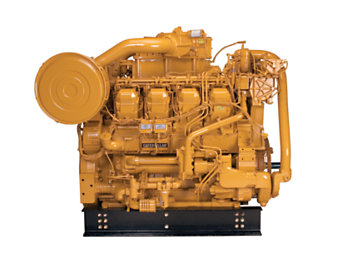

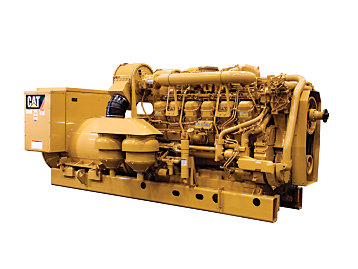

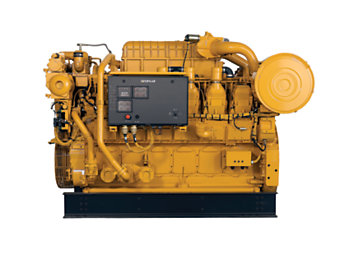

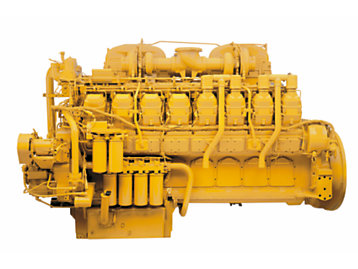

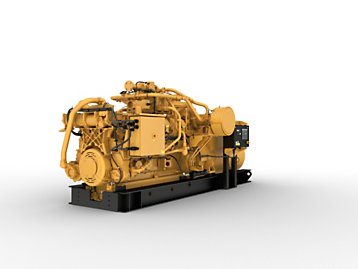

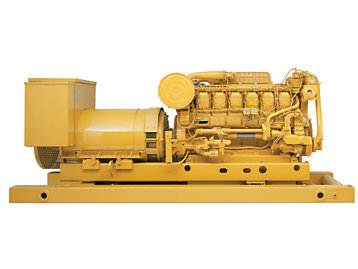

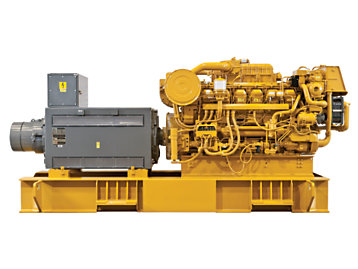

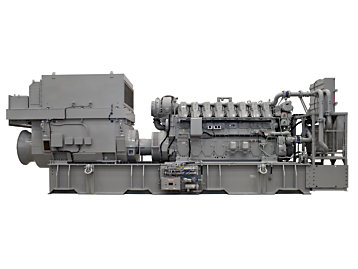

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

- More than 2,200 dealer outlets - Cat factory-trained dealer technicians service every aspect of your Cat petroleum product - Worldwide parts availability, service, and warranty - Preventive maintenance agreements available for repairbefore- failure opti

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

For all your petroleum power requirements, visit www.cat.com/oilandgas.