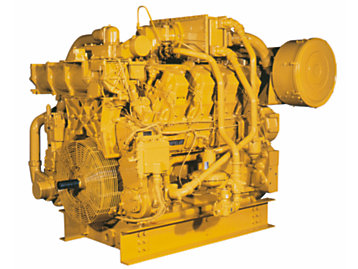

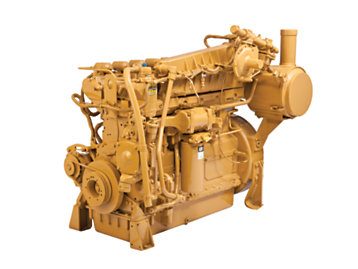

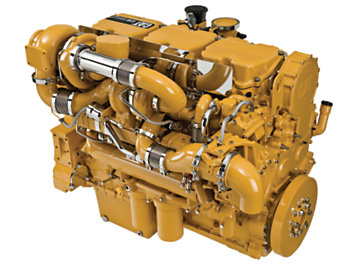

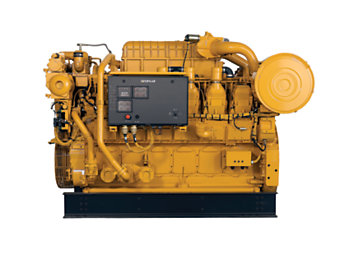

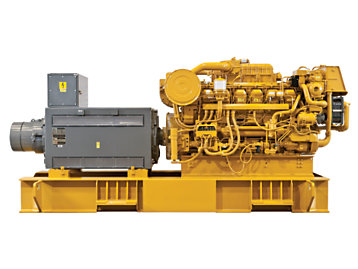

Separate Circuit Aftercooler (SCAC) and Air-to-Air-Aftercooler (ATAAC)

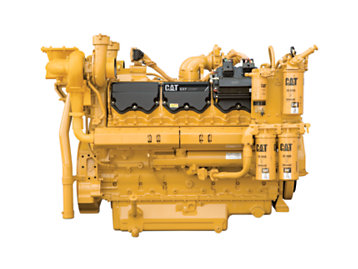

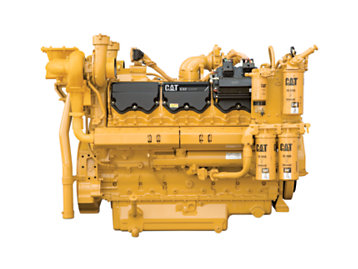

Integrates with engine, aftertreatment, heavy-duty air cleaners, residential grade mufflers available in stainless or carbon steel

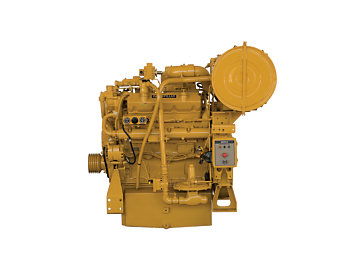

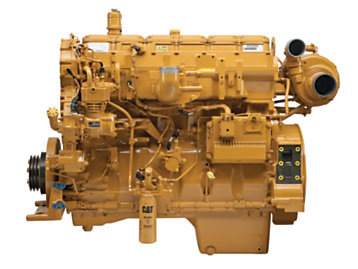

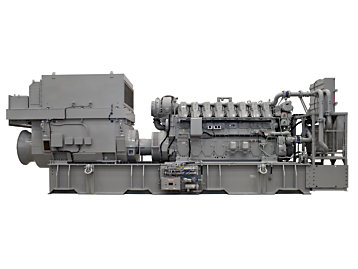

ADEM A6 DGB based controls seamlessly integrated with A5 engine management system.

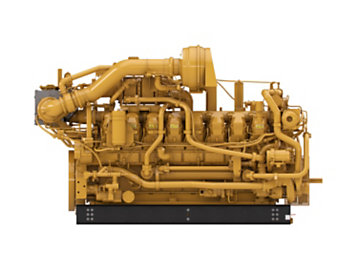

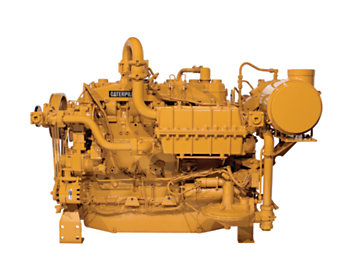

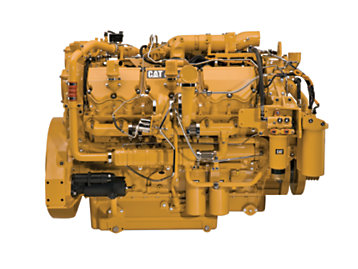

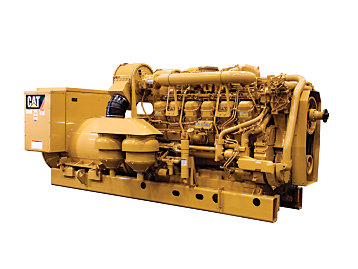

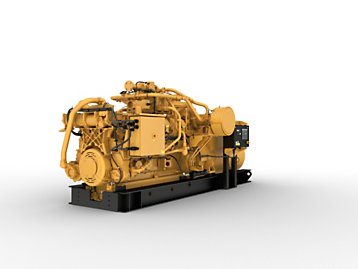

For any petroleum application, trust Caterpillar to meet your exact needs with a factory custom package. Cat engines, generators, enclosures, controlsCustom Packaging , radiators, transmissions – anything your project requires – can be custom designed and matched to create a one-of-a kind solution. Custom packages are globally supported and are covered by a one-year warranty after startup.

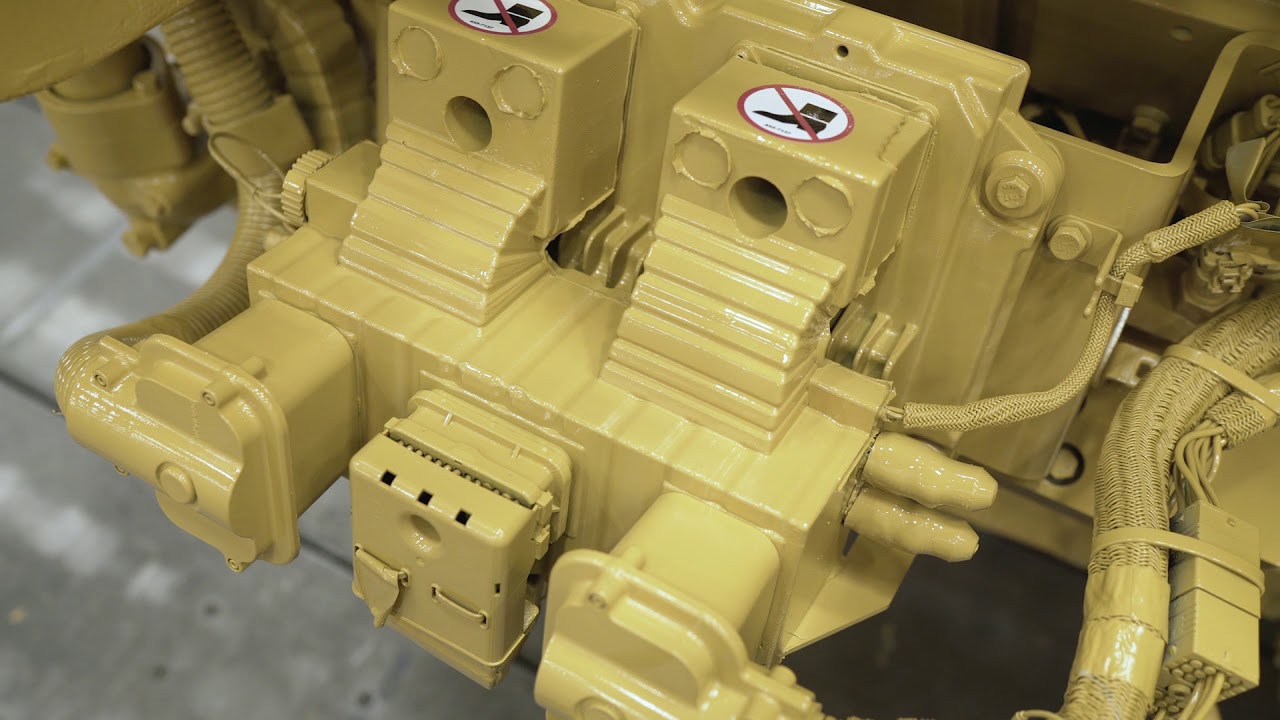

Large variety of factory-installed engine attachments reduces packaging time

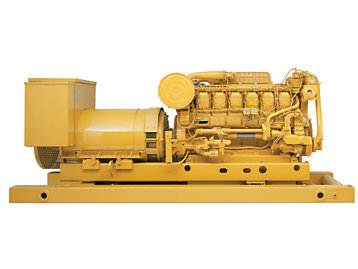

Every engine is full-load tested with diesel fuel and with natural gas to ensure proper engine performance.

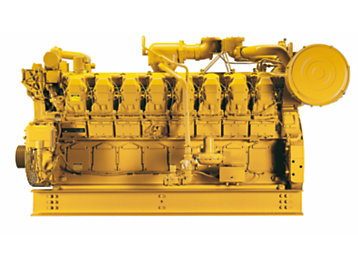

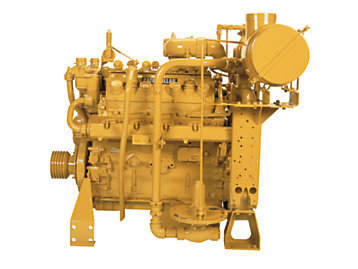

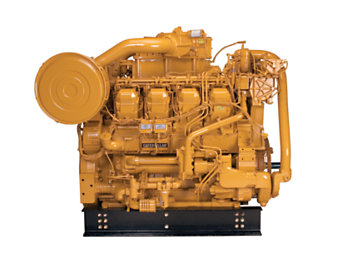

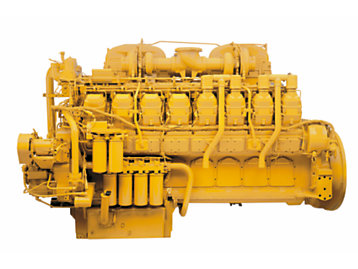

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

- Cast engine blocks, heads, cylinder liners, front and flywheel housings

- Machine critical components

- Assemble complete engine