If you already have an existing account with another Cat App, you can use the same account to sign in here.

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

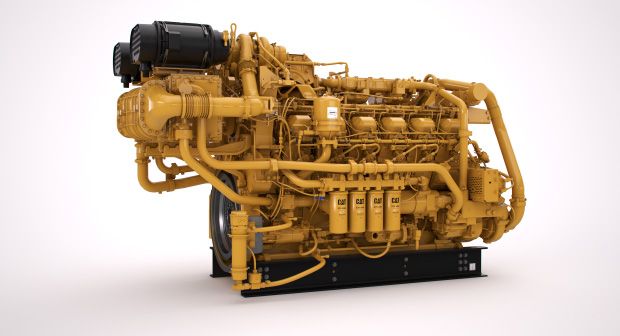

Transitioning Onshore Drilling Rigs to EPA Tier 4 Final Engines

A CLOSER LOOK AT 3512E TECHNOLOGY, INSTALLATION, PERFORMANCE AND MORE

Diesel engine manufacturers began preparing for U.S. EPA Non-Road Mobile Tier 4 emissions standards prior to 2011, the year OEMs were required to start complying with standards for engines rated at 750 hp and above. Between 2011 and 2017, most North American onshore drillers and OEMs took advantage of the EPA’s flexibility provisions, which allowed continued use of Tier 2 engines in new rigs in limited quantities. Now that this flexibility period has ended, onshore drillers and OEMs must make plans for implementing Tier 4 Final engines in new rigs.

The information below will help you compare the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine to the previous Tier 2 model, the 3512C, as you prepare to transition your rigs to meet emissions standards. In terms of overall performance, the 3512E meets or exceeds 3512C standards in nearly every category, delivering the same power over the same operating range.

EMISSIONS-REDUCTION TECHNOLOGIES

Controlling emissions from a diesel engine is a balancing act. Measures taken to reduce NOx often increase PM, HC and CO emissions and vice versa.

To meet both application requirements and customer needs, the Cat 3512E Tier 4 Final engine for land drilling uses an optimal combination of emissions-reduction technologies. It’s proven in the field to meet or exceed the reliability standards set by the 3512C without the burden of complex aftertreatment systems or secondary fluid requirements.

Exhaust Gas Recirculation to Reduce NOx

NOx typically forms at high combustion temperatures inside the engine cylinders. Exhaust Gas Recirculation (EGR) reduces the oxygen level and peak combustion temperature inside the cylinder, thereby reducing NOx formation. The 3512E’s NOx Reduction System (NRS) cools and meters the re-circulated exhaust gas.

High-Pressure Fuel Injection System to Reduce PM

PM generally forms due to an uneven air-fuel mixture and combustion inefficiencies within the cylinder. Two common technologies for PM reduction are high-pressure fuel injection and Diesel Particulate Filters (DPF), which filter PM from the exhaust stream. The 3512E uses a high-pressure fuel injection system to finely atomize the fuel mixture in the cylinder and minimize the formation of PM, thereby eliminating the need for a DPF.

Diesel Oxidation Catalyst to Reduce HC and CO

A compact, maintenance-free device that also offers additional exhaust sound attenuation, the 3512E’s Diesel Oxidation Catalyst (DOC) reduces HC and CO to CO2 and water vapor.

Eliminating the Challenges of Selective Catalytic Reduction

An alternative approach to meeting Tier 4 Final emissions standards, Selective Catalytic Reduction (SCR) is an aftertreatment technology that injects Diesel Exhaust Fluid (DEF) into the exhaust to reduce NOx to nitrogen and water vapor with the aid of a catalyst element. For land drilling, SCR technology poses significant challenges:

- The size and arrangement of the aftertreatment, DEF storage tanks, DEF pumping units and associated piping are prohibitive on a land drilling rig.

- Land drilling sites are typically in remote locations. Onsite storage and distribution of large quantities of DEF requires additional logistics and handling.

- DEF freezes at 12°F and shelf life decreases dramatically at temperatures above 90°F.

- DEF injection systems are sensitive to contamination, requiring special closed-loop storage and delivery systems and robust contamination control procedures to prevent equipment malfunctions.

- A loss of DEF or issues with the delivery system can trigger engine de-rates or shutdowns.

SYSTEM INSTALLATION

The 3512E fits into the same footprint as the 3512C, with the NRS and common rail fuel system components factory-installed. The most significant changes to 3512E installation relate to the exhaust and cooling system.

Exhaust System

The exhaust system includes a single DOC between the turbocharger outlet and muffler. The DOC can be mounted in a variety of locations and orientations to fit the design of the exhaust and roof structure with no effect on the overall size of the master skid.

Cooling System

The NRS cools re-circulated exhaust air before returning it to the intake air stream, resulting in higher overall engine heat rejection. However, a new two-stage aftercooler on the 3512E offsets nearly all of the impact on the size of the radiator or cooler. Minor changes to fan designs and speed also minimize the effect on cooling system size.

FUEL CONSUMPTION

Though EGR technology is commonly thought to increase fuel consumption, the 3512E offers better fuel consumption than the 3512C. Comparing identical drilling load profiles, it consumes 2 percent less diesel. In addition, since there is no SCR system, there is no added fluid consumption or cost in the form of DEF or urea.

3512E engine controls use the same direct rack throttle controls as the 3512C with the capability to add Smart Engine Management System (Smart EMS). Smart EMS is a system-level integration that actively manages the number of engines online to match rig load demand, thereby keeping individual engines running at optimal loads where they are more fuel efficient. The included EMCP 4.4 control panel makes it possible to automate engine power management on a drilling rig, with field tests showing average fuel efficiency improvements of up to 10 percent and engine run time reductions of up to 25 percent.

OPERATIONS & MAINTENANCE

The 3512E maintains or improves on 3512C service intervals with the same maintenance procedures and scheduling. It also includes Product Link™ remote monitoring, making it possible to track productivity and engine health by engine, rig or fleet anywhere in the world.

|

3512C (Tier 2) |

3512E (Tier 4 Final) |

Fuel spec (sulfur ppm) |

500 ppm |

15 ppm (EU = 10 ppm) |

Required oil spec |

ECF-2 (CI-4) |

ECF-3 (CJ-4) (CK-4) (ACEA #9 or JAS DH-2 that meet CJ-4) |

Fuel consumption |

Base |

Reduced1 |

Control system |

ADEM A3 |

ADEM A5 |

Control panel |

Engine Instrument Panel |

EMCP 4.4 with Product Link |

Closed crankcase ventilation |

None available |

Optional |

Service intervals (air, oil, fuel)2 |

250, 500, 1000 hours |

250, 500, 1000 hours |

Valve lash |

4000 hours |

4000 hours |

Alternator |

Tensioning required |

Auto tensioning |

Published overhaul life3 |

11,000/22,000/33,000 hours |

16,500/33,000 hours |

1 Application specific. 2 Targets based on maintenance practices and location. 3 Depends on operation and maintenance practices.

Related Articles

-

Cat Smart EMS

What if you could reduce runtime on your drilling rig engines up to 25 percent, cut fuel consumption up to 10 percent and increase gas consumption as well — without sacrificing power and productivity? With Smart EMS, you can.

Learn More -

EGR Fact VS. Fiction

Let’s get to the truth about land drilling engines featuring Exhaust Gas Recirculation (EGR) technology — specifically the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine.

Learn More -

EGR Fact VS. Fiction

Let’s get to the truth about land drilling engines featuring Exhaust Gas Recirculation (EGR) technology — specifically the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine.

Learn More -

EMCP 4.4

If you’re still using EIP (Electronic Instrument Panel) to monitor your rig’s engines, it’s time for an upgrade. This easy-to-use control panel, proven in the electric power industry, simplifies diagnostics and troubleshooting.

Learn More -

EMCP 4.4

If you’re still using EIP (Electronic Instrument Panel) to monitor your rig’s engines, it’s time for an upgrade. This easy-to-use control panel, proven in the electric power industry, simplifies diagnostics and troubleshooting.

Learn More -

Emissions Acronyms, Decoded

It’s not easy to remember all the acronyms associated with U.S. EPA Tier 4 Final emissions standards for land drilling rigs. Use this simple guide to keep the terminology straight.

Learn More -

Emissions Acronyms, Decoded

It’s not easy to remember all the acronyms associated with U.S. EPA Tier 4 Final emissions standards for land drilling rigs. Use this simple guide to keep the terminology straight.

Learn More -

Transitioning Onshore Drilling Rigs to EPA Tier 4 Final Engines

Use this white paper to compare the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine to the previous Tier 2 model, the 3512C, as you prepare to transition your rigs to meet emissions standards.

Learn More -

Why EGR for Land Drilling?

Both Exhaust Gas Recirculation (EGR) and Selective Catalytic Reduction (SCR) have their strengths when it comes to emissions reduction, but when you look at the facts, EGR is the clear winner on land.

Learn More -

Why EGR for Land Drilling?

Both Exhaust Gas Recirculation (EGR) and Selective Catalytic Reduction (SCR) have their strengths when it comes to emissions reduction, but when you look at the facts, EGR is the clear winner on land.

Learn More -

You asked, We Delivered

Land drilling customers told us they had five big requirements for Tier 4 Final engines — here’s how the 3512E delivers on all of them.

Learn More -

You asked, We Delivered

Land drilling customers told us they had five big requirements for Tier 4 Final engines — here’s how the 3512E delivers on all of them.

Learn More