- VisionLink® provides actionable data insights for all assets - regardless of fleet size or equipment manufacturer.* Review equipment data from your desktop or mobile device to maximize uptime and optimize assets. Dashboards provide information such as hours, miles, location, idle time, and fuel utilization. Make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

- VisionLink® Productivity gathers and summarizes machine telematics and jobsite data from all your equipment – regardless of the manufacture.* View actionable information such as idle time, fuel burn, location, payload, load counts, total cycles, and more to improve machine efficiency, productivity, and utilization. Access data anywhere via a mobile, tablet, or desktop device - on or off the jobsite.

- Cat® Inspect is a mobile application that allows you to easily perform digital preventative maintenance (PM) checks, inspections, and daily walkarounds. Inspections can easily be integrated with other Cat data systems like VisionLink® so you can keep a close eye on your fleet.

- Remote Troubleshoot is a mobile application that allows your Cat dealer to perform diagnostic testing on your connected machine remotely to help ensure that issues are resolved quickly and with less downtime.

- Remote Flash is a mobile application that allows you to update onboard software without a technician being present, allowing you to initiate software updates when convenient, increasing your overall operating efficiency.

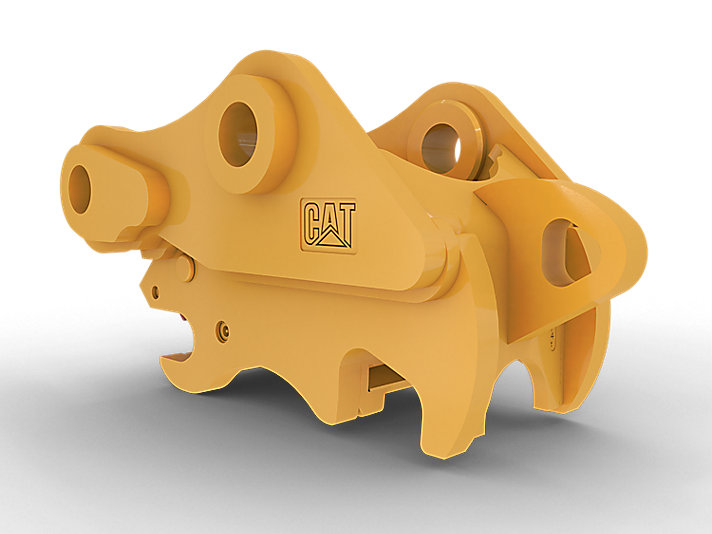

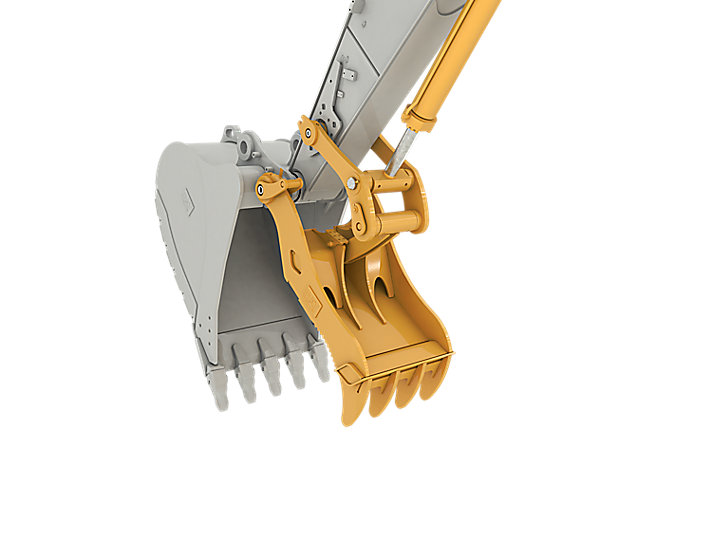

- The Cat PL161 attachment locator allows you to track attachments across all worksites, reduce the number of lost attachments, and plan for attachment maintenance and replacement. The work tool recognition feature automatically adjusts machine settings based on the selected tool.

* Data field availability can vary by equipment manufacturer.